Method for erecting girder of suspension bridge by double-hoisting hydraulic NC (numerical control) cable crane

A technology of suspension bridges and cranes, applied in the construction of suspension bridge main girders and the field of suspension bridge main girder erection equipment, which can solve the problems of inability to solve the needs of bridge erection construction, difficult to ensure the safety of girder sections, and short hoisting section lengths, etc. Achieve excellent performance, improve worker proficiency, and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

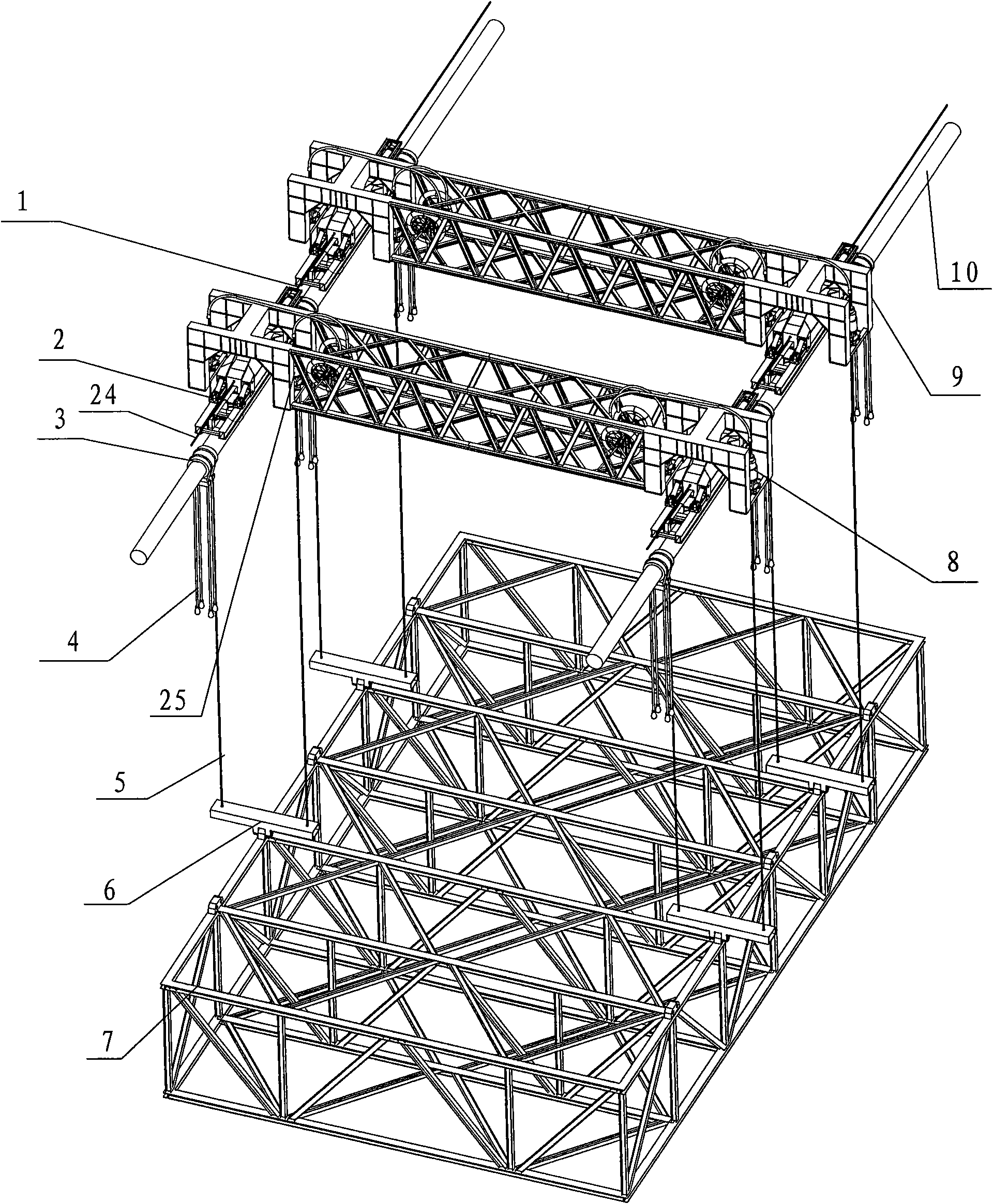

[0050] A double-machine double-hanging hydraulic numerical control cable spanning crane, including 2 sets of cable spanning cranes and control systems. The cable crane comprises a transverse truss girder 9, two sets of walking-type load-carrying devices 2 installed at both ends of the transverse truss girder 9, four parts of a hydraulic lifting device 8 and a spreader shoulder pole 6 (see figure 1 );

[0051] The main girder 9 of the transverse truss is formed by connecting the two ends of the truss 22 welded by H-shaped steel to the double-door-shaped load beam 23, and the space of the truss is used to place the take-up reel 26, the hydraulic pump station, the main console and the construction personnel. Work platform; The top of double-door glyph load beam 23 is provided with bearing pin 15 (referring to Figure 5 );

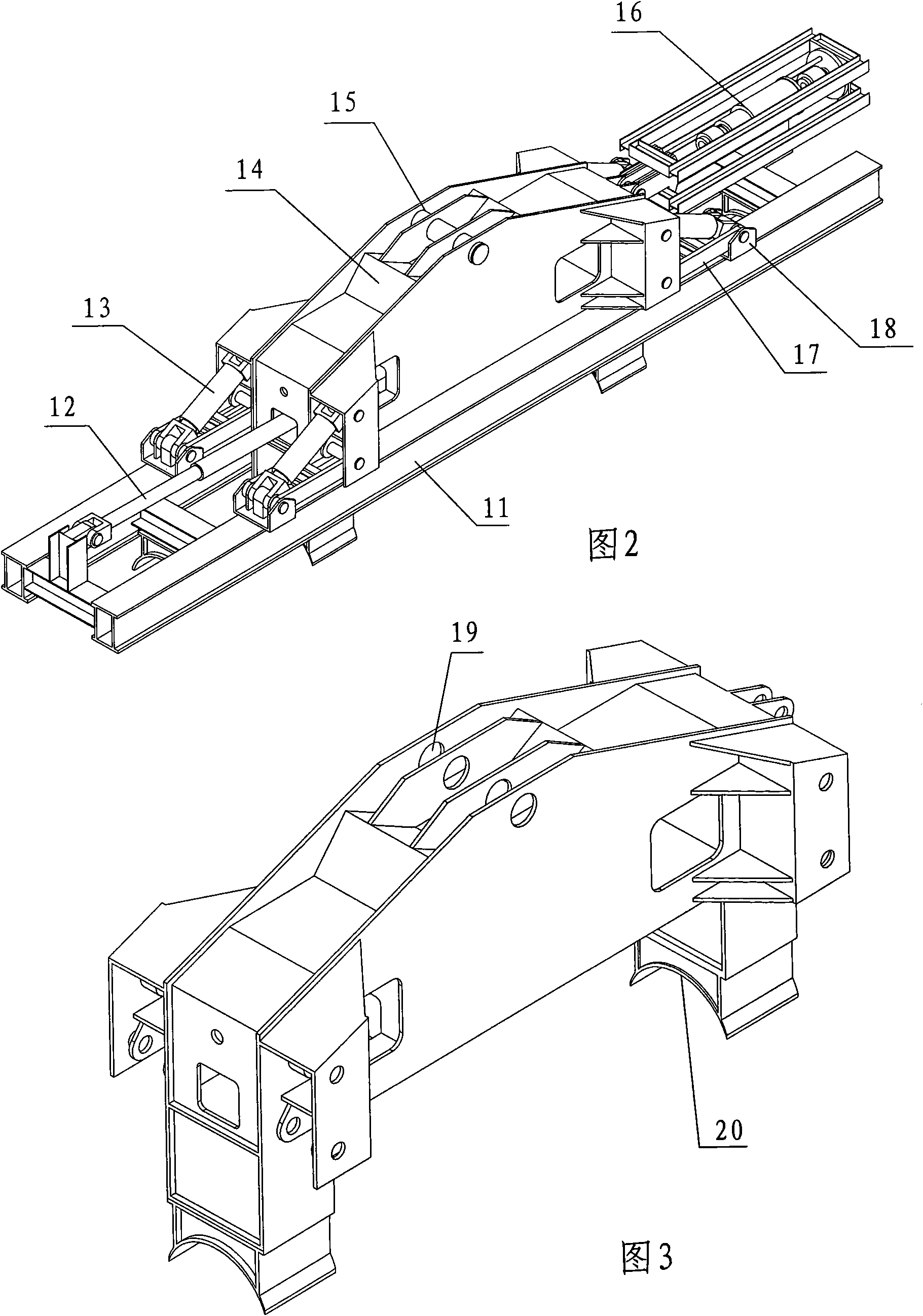

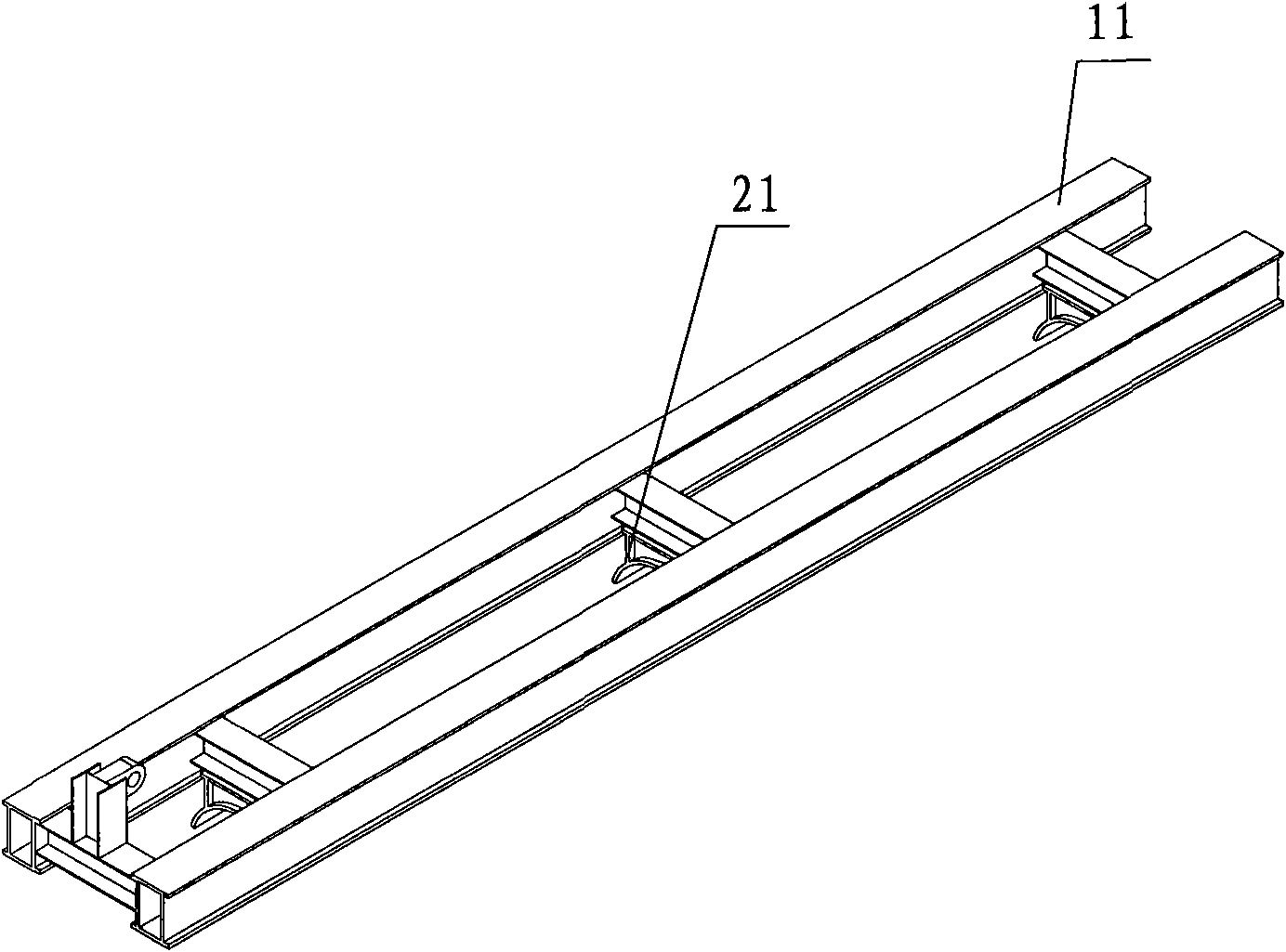

[0052] Each set of walking-type load-bearing traveling device 2 is composed of guide rail 11, steel frame of traveling mechanism 14, 1 set of traction jack ...

Embodiment 2

[0059] A method for erecting the main girder of the suspension bridge is applicable to when the main girder of the suspension bridge is erected downhill from the tower end to the mid-span.

[0060] When the main girder of the suspension bridge is erected downhill from the tower end to the mid-span, the above-mentioned double-machine double-hoist hydraulic numerical control spanning cable crane and double-machine load-carrying girder erection of the present invention are used to transport each steel truss beam section 7 from both sides to the middle of the suspension bridge. Set up, the steps of its operation are:

[0061] A. Install the cable span crane: Install the transverse truss girders 9 of the two cable span cranes parallel to each other, and connect them through the hinged steel connecting rod 1; the steel truss beam section 7 is hung on the two span cable Four sets of spreader shoulder poles 6 with a total of eight lifting points on the crane ensure the overall stabili...

Embodiment 3

[0079] A method for erecting the main girder of the suspension bridge when erecting the main girder of the suspension bridge uphill along the main cable.

[0080] When the beam section is erected from the mid-span to the two banks, the flat section is erected with the truss girder under the load of the cable-span crane. For uphill side spans with large slopes, two sets of load-carrying hydraulic numerical control spanning cable cranes are used for self-swaying and truss girder operation.

[0081] The specific steps of using two sets of load-carrying hydraulic numerical control cross-cable cranes to swing and erect by themselves are as follows:

[0082] A, installation of cross-cable cranes: the horizontal truss girders (9) of two cross-cable cranes are installed parallel to each other, and the steel truss beam section 7 is installed under two cross-cable cranes by spreaders;

[0083] B. Vertical lifting: steel truss beam section ( Figure 23-1 );

[0084] C. Two sets of cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com