Pressive bending resistance optical cable and manufacturing method thereof

A technology of anti-bending and optical cables, which is applied in the manufacturing field of pressure-resistant and anti-bending optical cables. Effect of interruption, good temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The pressure-resistant and bending-resistant optical cable of the present invention will be described in detail below with reference to the figures.

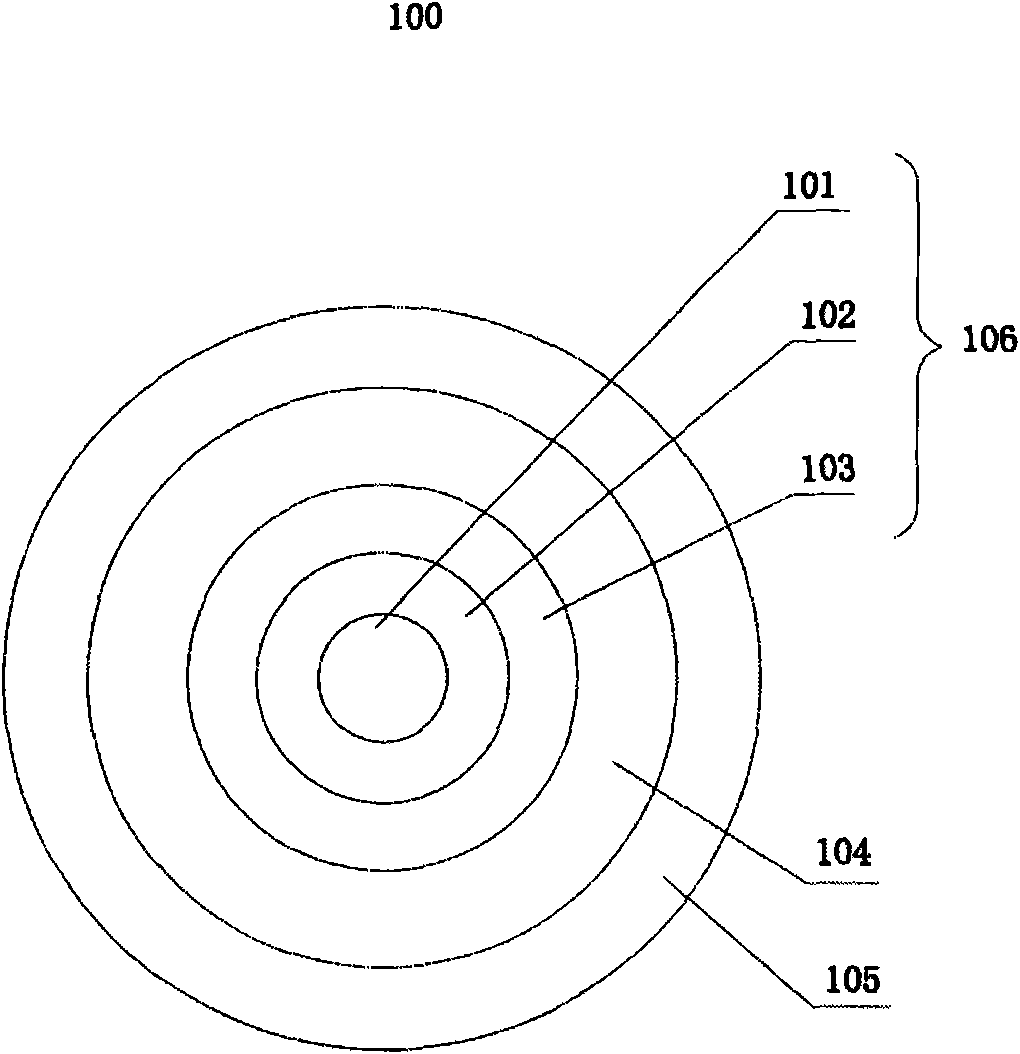

[0023] see figure 1 , is a schematic cross-sectional structure diagram of a preferred embodiment of the pressure-resistant and bending-resistant optical cable of the present invention. like figure 1 As shown, the pressure-resistant and bending-resistant optical cable 100 has a circular cross-section, including an optical fiber 101 , a first tight cladding 102 , a second tight cladding 103 , an aramid yarn 104 and a sheath 105 arranged sequentially from inside to outside. The first tight envelope 102 and the second tight envelope 103 constitute a tight envelope. The optical fiber 101 , the first tight cladding 102 and the second tight cladding 103 together form a tight-buffered fiber 106 . Wherein, the sheath 105 can be made of flame retardant materials such as PVC (Polyvinylchlorid, polyvinyl chloride), LSZH (Low Smoke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com