Portal type silicon chip transfer mechanism

A gantry-type, silicon wafer technology, applied in conveyor objects, sustainable manufacturing/processing, electrical components, etc., can solve the problems of wasting human resources, low efficiency in taking wafers, and high labor intensity, reducing production costs and overcoming manual labor. Operation, the effect of improving transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

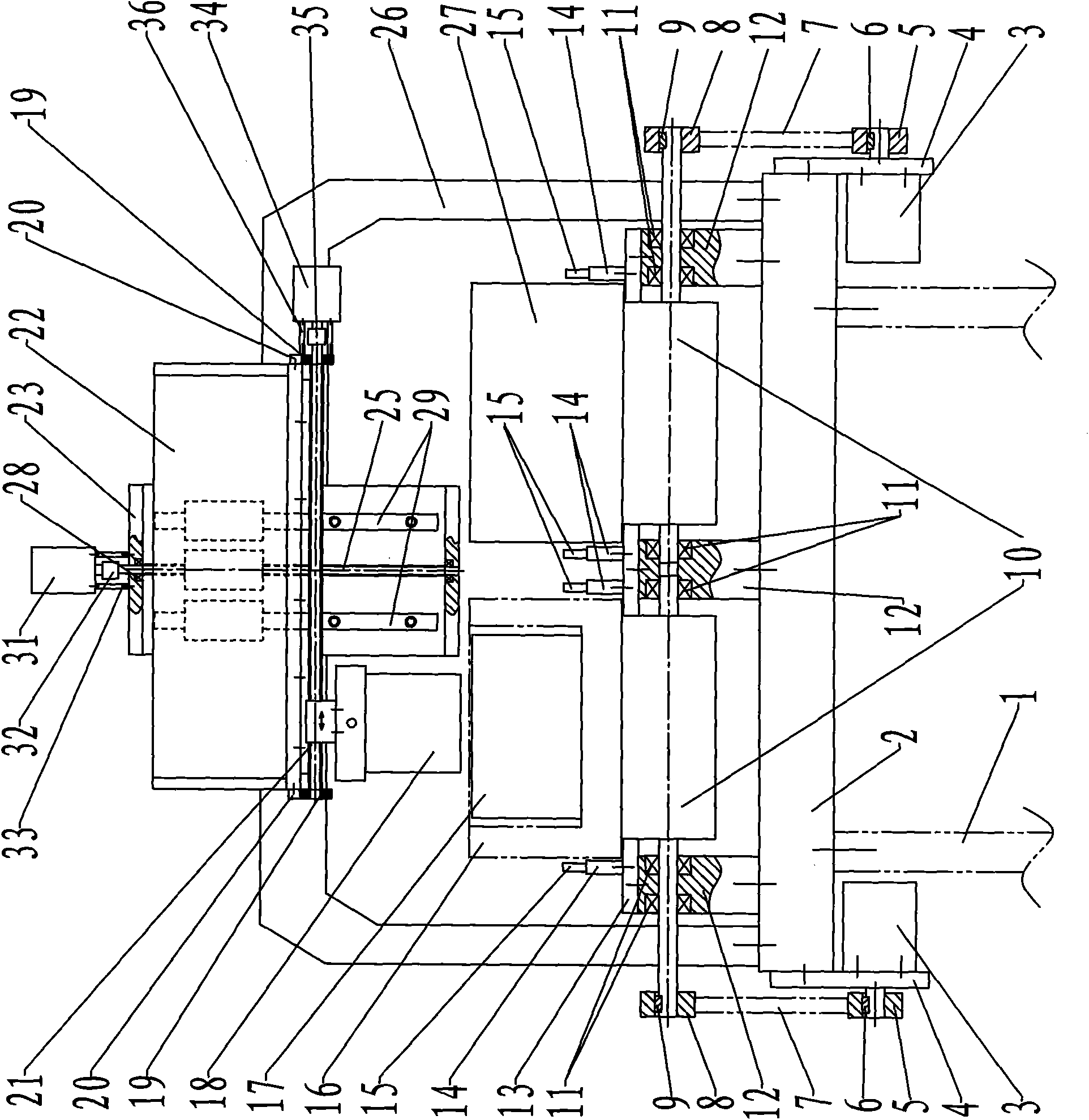

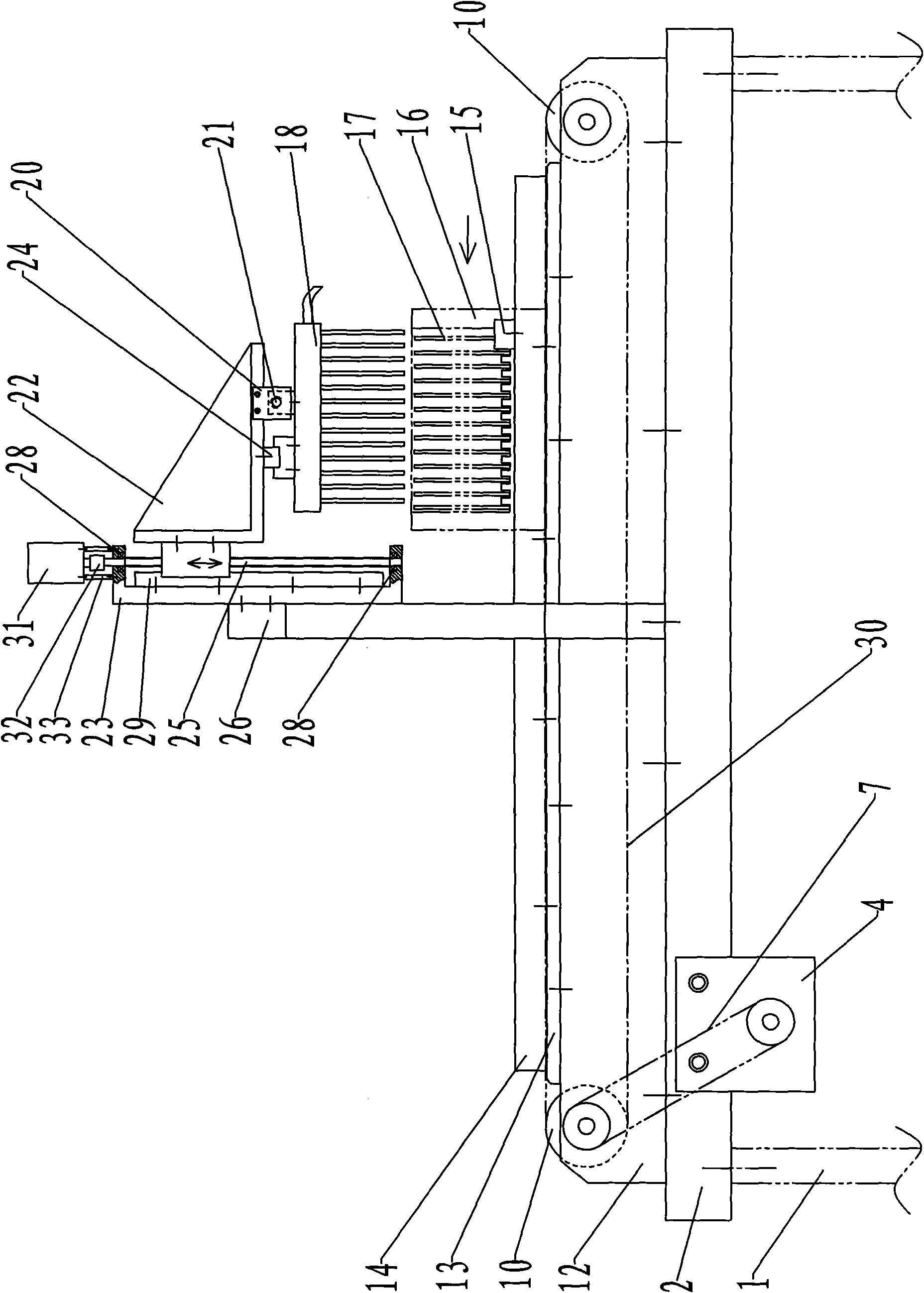

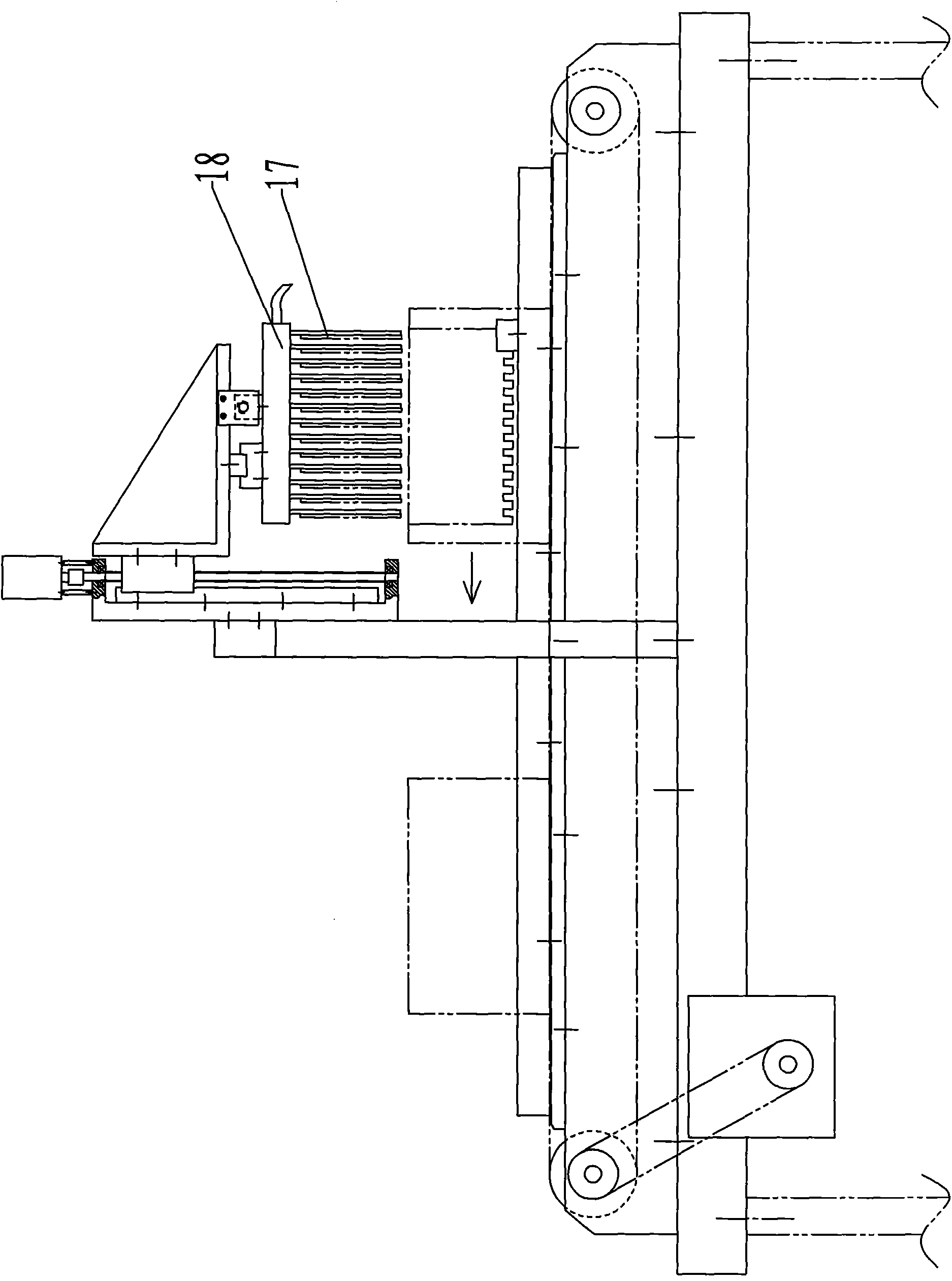

[0015] As shown in the figure, the present invention is mainly made up of frame 1 and the conveying platform installed on frame 1, lifting device and mobile sucker device. A table panel 2 is fixed on the frame 1, and a gantry frame 26 is installed on the table panel 2; It is used to transport and position the silicon wafer box 16 and the quartz frame 27; the lifting device is installed on the gantry 26, and the lifting device is provided with a lifting seat 22, and the mobile suction cup device is installed on the lifting seat 22, and the lifting device is used to drive the mobile suction cup device up and down Lifting; the mobile sucker device is provided with a chip sucker 18, which can control the lateral movement of the chip sucker 18, and the chip sucker 18 is used to suck the silicon wafer 17 in the silicon wafer box 16 and transfer the sucked silicon waf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap