Industrial robot motion planning and performance testing system and implementation method thereof

A robot movement and testing system technology, applied in manipulators, manufacturing tools, etc., can solve the problems of lack of performance evaluation and analysis system, poor versatility, single function, etc., to achieve fast programming speed, save working time, work efficiency and Effect of Accuracy Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

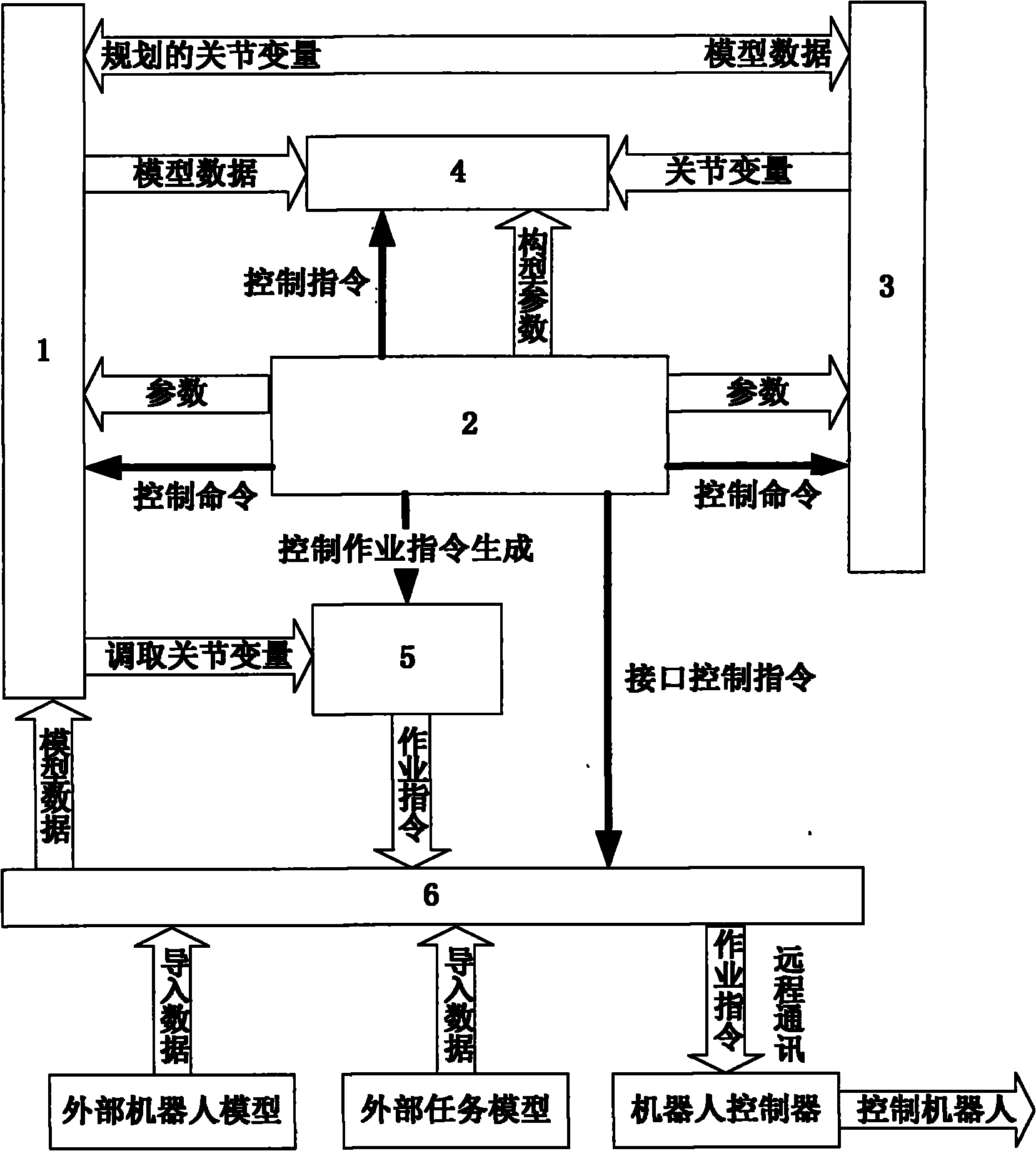

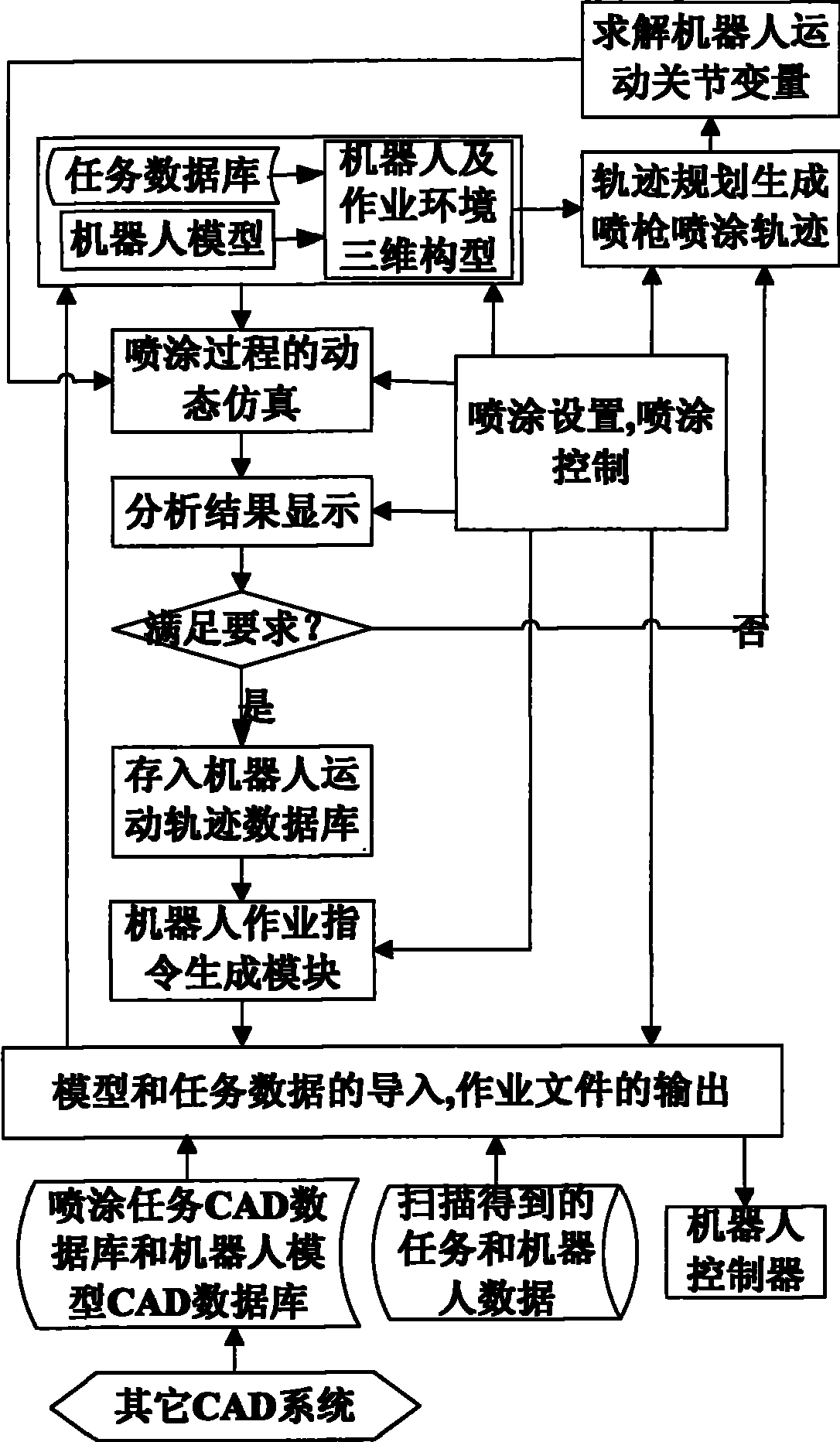

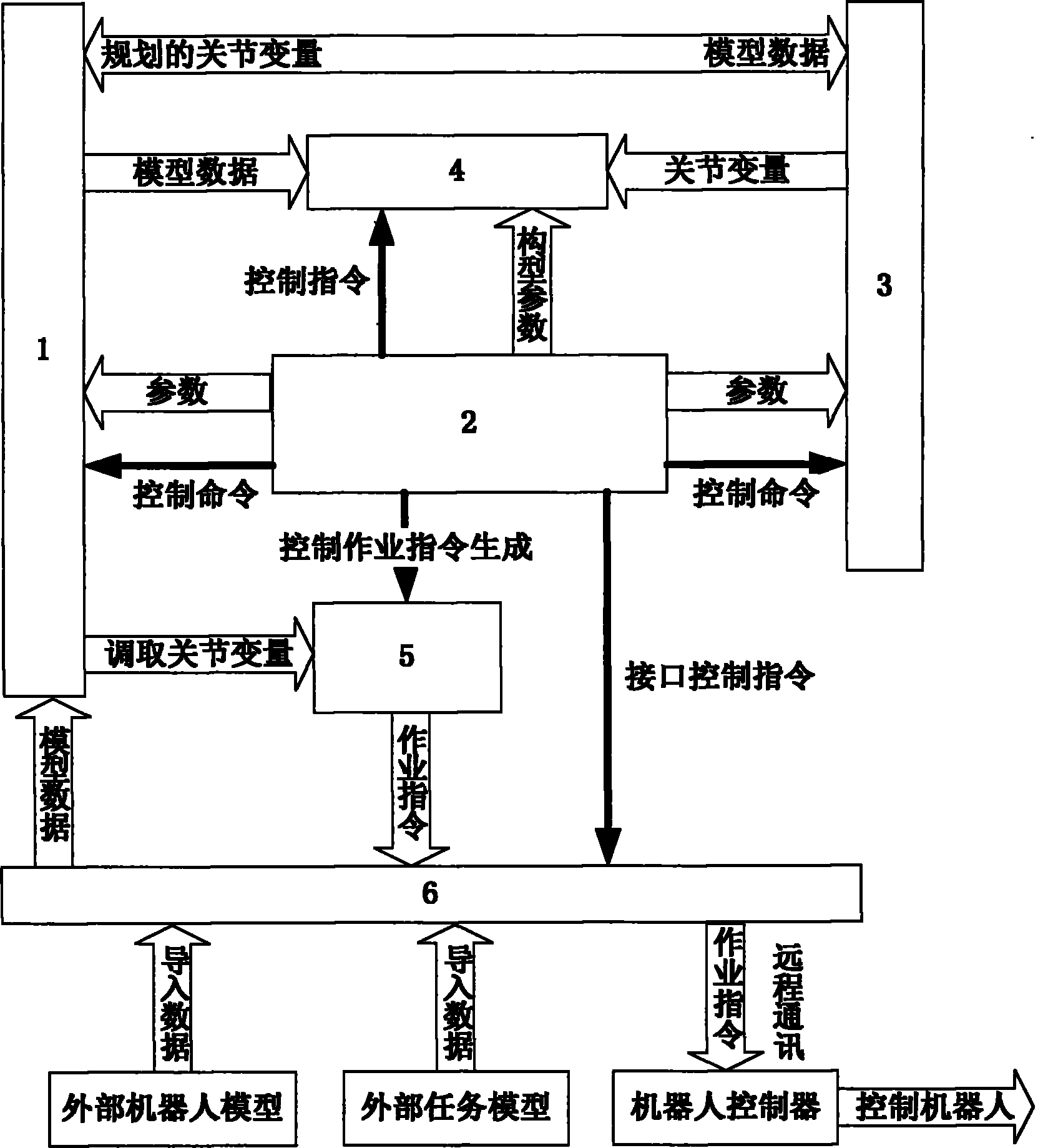

[0029] The structure diagram of the present invention is as figure 1 As shown, below in conjunction with accompanying drawing, the example of the present invention is described, present embodiment takes content of the present invention as technical scheme, realizes the off-line programming of MOTOMAN robot, is an application of the present invention, has provided the specific of present embodiment below operation process.

[0030] Such as figure 1 As shown, the components involved in this embodiment include: MOTOMAN robot (not shown on the figure) and its controller, the comprehensive platform for off-line programming of the spraying robot of the present invention, communication cables, etc.

[0031] The comprehensive platform for off-line programming of spraying robot in this example includes six main functional modules: database module, human-computer interaction module, spray gun trajectory planning module, analysis and display module, job file generation module, communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com