Manufacturing method of heat-resistant ultrawear-resistant ametabolic composite board

A production method and composite board technology, which is applied in the production of non-deformable composite boards, high temperature resistance, super wear-resistant, and composite boards, and can solve problems such as durability, deformation, and peeling of the floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

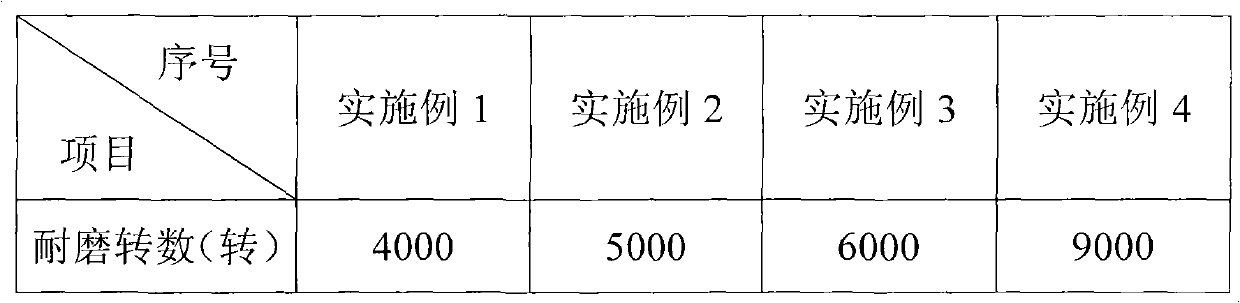

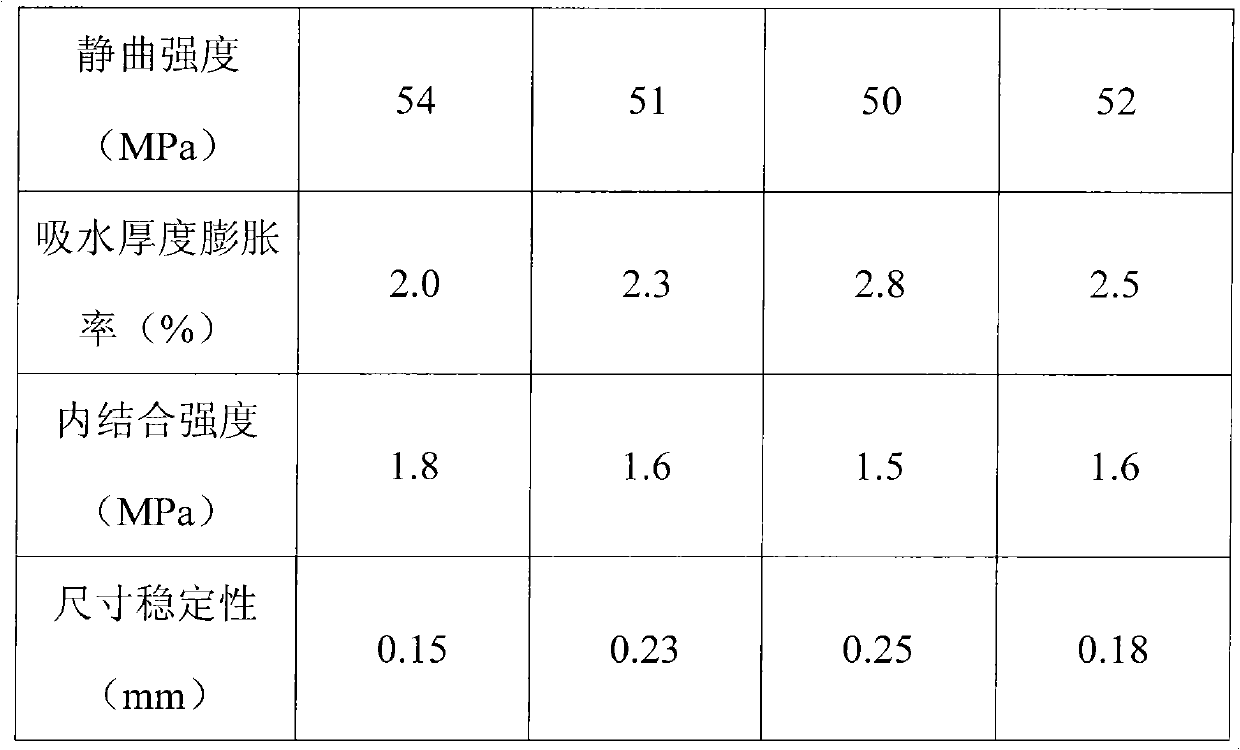

Examples

Embodiment 1

[0023] 1. Choose materials

[0024] 1. First choose 9mm thick multi-layer crisscross plywood (air-dry density is 6 moisture), 1 piece;

[0025] 2. Choose 6mm thick high-density fiberboard (density: 0.9 g / cm3), 2 pieces;

[0026] 3. Choose aluminum oxide paper (with a density of 24 g / m²), 1 sheet according to the environment where the customer applies the product;

[0027] 4. Choose decorative paper (density 80 g / m2), 1 piece according to the environment where the customer applies the product;

[0028] 5. Choose 1 piece of decorative paper (80 g / m²) that has been soaked in trihydroxide and dried;

[0029] 6. Choose 1 piece of balance paper (80g / m²) soaked in trihydroxide and dried;

[0030] Second, the specific production process

[0031] 1. The first step: first use two pieces of high-density fiberboard to sandwich the multi-layer crisscross plywood, and use melamine glue to bond the three through the high-pressure (2000 tons pressure) of the high-tonnage press, the pressure time is 18 Se...

Embodiment 2

[0037] 1. Choose materials

[0038] 1. First select 10mm thick multi-layer crisscross plywood (air-dry density is 9 moisture), 1 piece;

[0039] 2. Choose 4mm thick high-density fiberboard (density: 1.1 g / cm3), 2 pieces;

[0040] 3. According to the customer's application product environment, choose aluminum oxide paper (density 33 g / m2), 1 sheet;

[0041] 4. According to the environment in which the customer applies the product, choose a decorative paper (with a density of 100 g / m²), 1 sheet;

[0042] 5. Choose 1 piece of decorative paper (90 g / m²) that has been soaked in trihydroxide and dried;

[0043] 6. Choose 1 piece of balance paper (120g / m²) soaked in trihydroxide and dried;

[0044] Second, the specific production process

[0045] 1. The first step: First, sandwich the multi-layer crisscross plywood with two pieces of high-density fiberboard, and use melamine glue to bond the three through the high-pressure (2400 tons pressure) of the high-tonnage press, the pressure time is 15 S...

Embodiment 3

[0051] 1. Choose materials

[0052] 1. First select 18mm thick multi-layer crisscross plywood (air-dry density is 12 moisture), 1 piece;

[0053] 2. Choose 1mm thick high-density fiberboard (density: 1.3 g / cm3), 2 pieces;

[0054] 3. According to the customer's application product environment, choose aluminum oxide paper (density 46 g / m2), 1 sheet;

[0055] 4. Choose decorative paper (with a density of 120 g / m²), 1 piece according to the environment where the customer applies the product;

[0056] 5. Choose one piece of decorative paper (100 g / m²) that has been soaked in trihydroxide and dried;

[0057] 6. Choose 1 piece of balance paper (140 g / m²) that has been soaked in trihydroxide and dried;

[0058] Second, the specific production process

[0059] 1. The first step: first use two pieces of high-density fiberboard to sandwich the multi-layer criss-crossed plywood, and use melamine glue to bond the three through the high pressure (3000 tons pressure) of the high tonnage press, the press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com