Hydro-electric mixed driving system used for engineering machinery

A technology of hybrid drive and construction machinery, which is applied in the arrangement of multiple different prime movers of hybrid vehicles, motor vehicles, and general power units, etc. Unable to achieve normal operation and other problems, to achieve the effect of making full use of energy, improving operation reliability, and accelerating mechanism action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

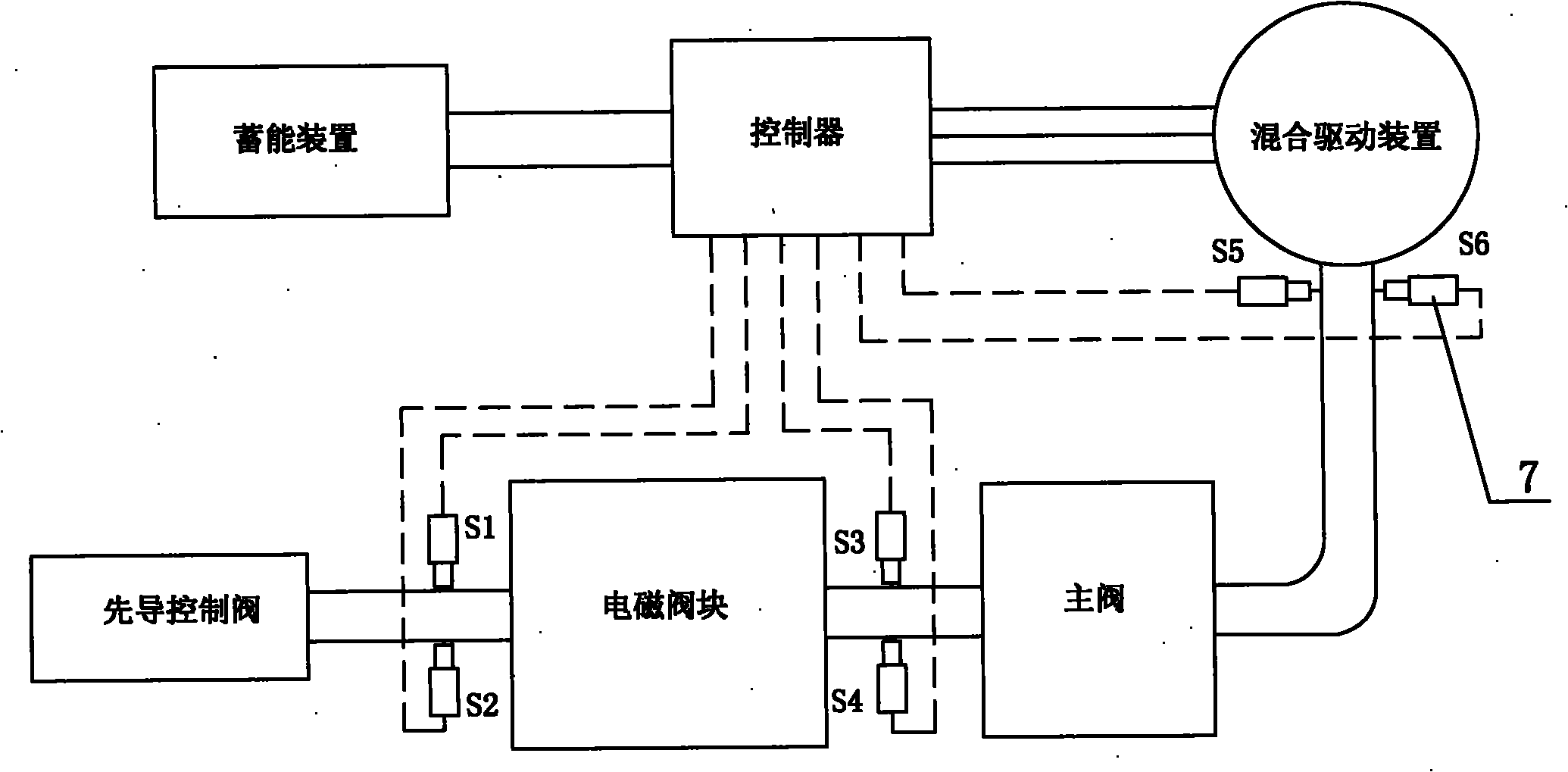

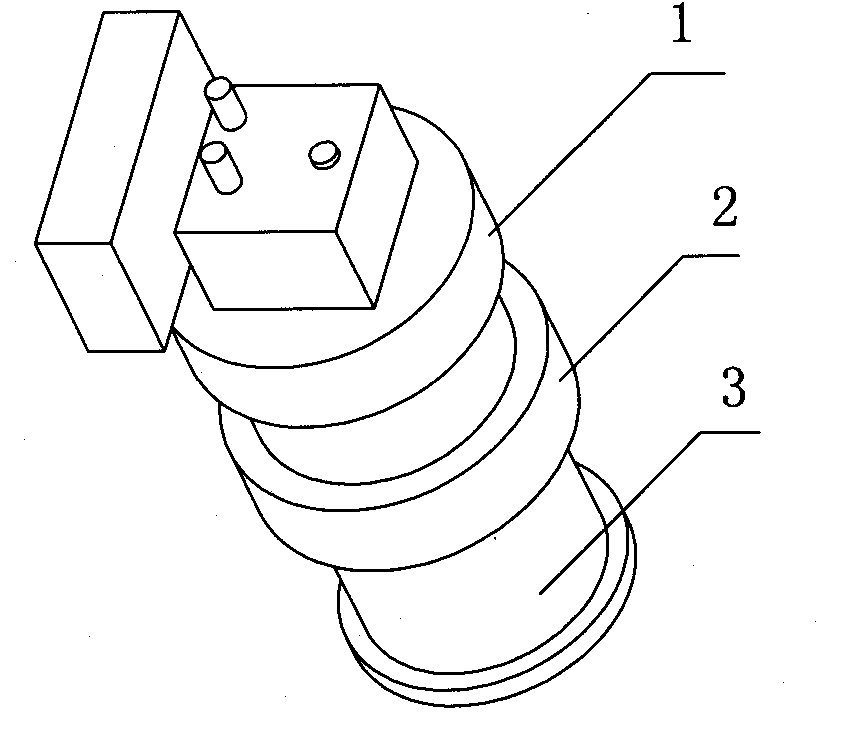

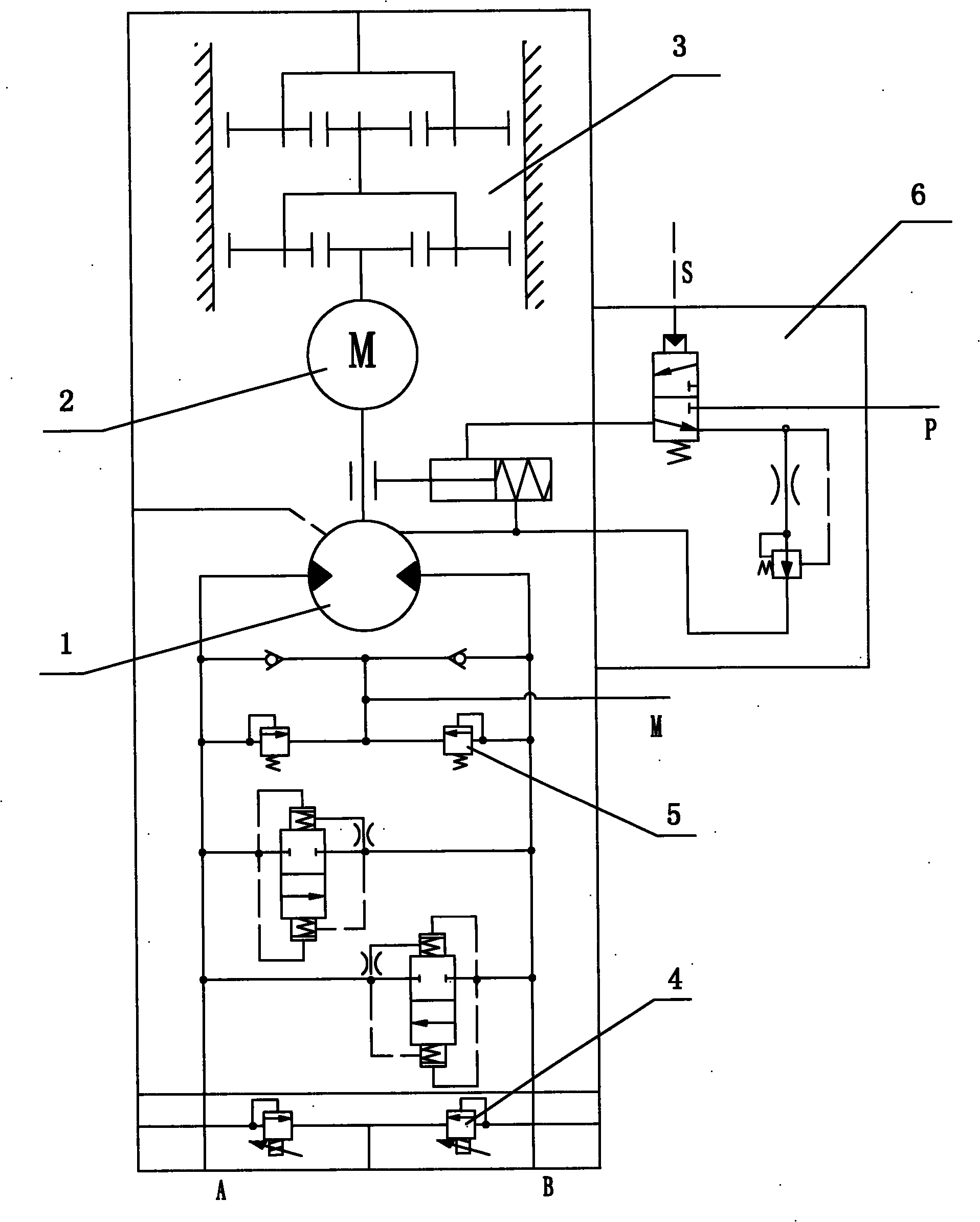

[0019] Embodiment one: see Figure 1~3 As shown, a hydraulic-electric hybrid drive system for engineering machinery includes a pilot control valve, a main valve, a power device and a controller, the output end of the power device is connected to the actuator, and the power device is a hybrid power device. It consists of a hydraulic motor 1, a motor generator 2 and a reducer 3 coaxially connected (such as image 3 shown).

[0020] In this embodiment, the actuator is a rotary platform on a hydraulic excavator, the moment of inertia of the platform is very large, and the braking of the platform is realized by the overflow of the hydraulic motor 1. During this process, the rotational kinetic energy of the platform is converted into thermal energy. Lost, this part of the energy lost in the past is converted into heat energy of the hydraulic oil, and the heat dissipation burden of the heat dissipation system is heavy, which leads to high energy consumption of the whole machine. Now...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com