Three-cylinder type large-capacity magneto-rheological damper

A magnetorheological damper and magnetorheological damping technology, applied in solid shock absorbers, building components, shockproof, etc., can solve the problems of heavy construction, limited vibration control effect, limited damping force, etc., and meet the requirements of earthquake resistance and wind resistance Requirement, reduction of high-frequency transmissibility, remarkable effect of shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

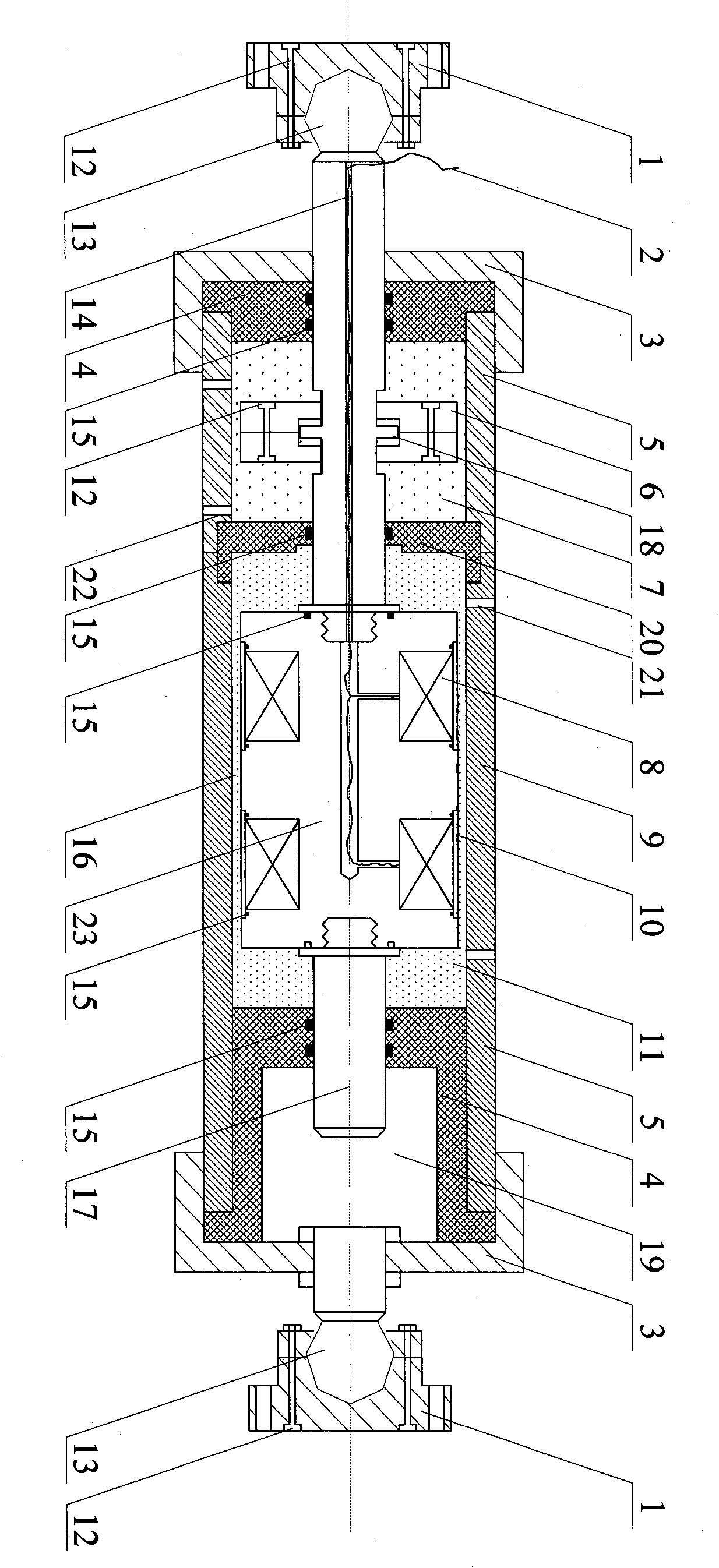

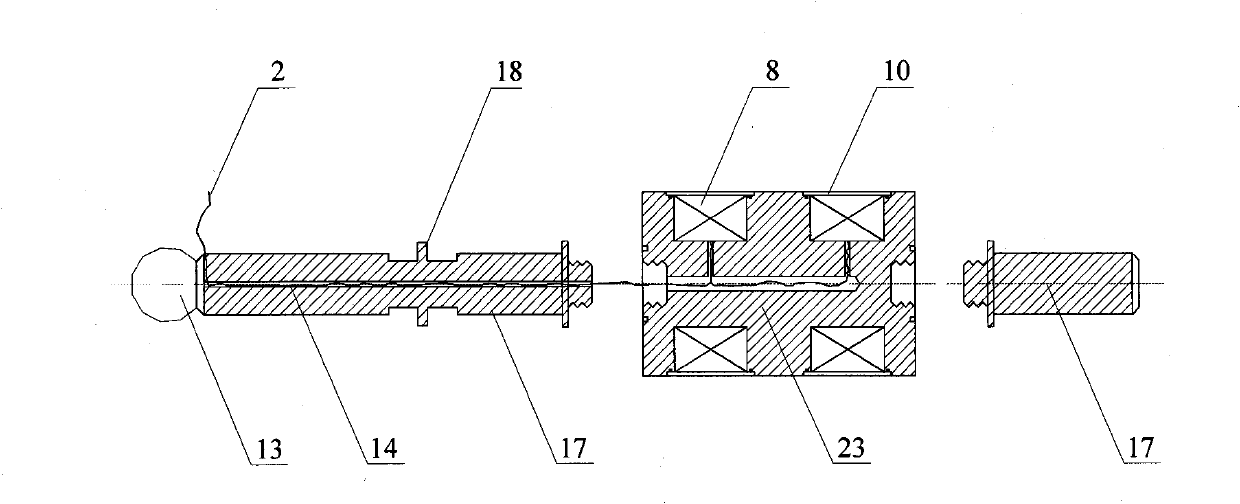

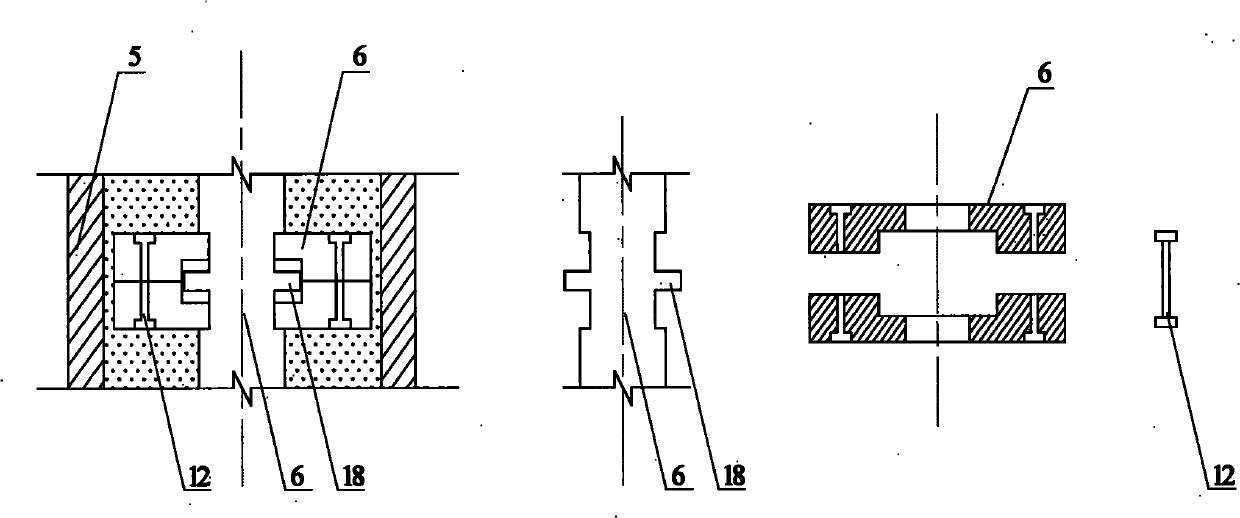

[0031] Such as figure 1 The three-cylinder type large output magnetorheological damper of the present invention as shown, it comprises magnetorheological damping cylinder (9), cement damping cylinder (5), auxiliary cylinder (19), magnetorheological main piston (23), cement Piston (6), sealing baffle (20), excitation coil (8), magnetorheological fluid (11), elastic cement (7), displacement decomposition ring (18), damping channel (16), cylinder head (3 ), spherical hinged joint (13). It is characterized in that the device is connected with a cement damping cylinder (5) at one end of the magnetorheological damping cylinder, the working cylinder (9) of the magnetorheological damper is filled with magnetorheological fluid (11), and the excitation coil ( 8), the excitation coil (8) is wrapped with a magnetic isolation sheath (10), and the piston is divided into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com