Centralized monitoring system for vulcanizer in tire factory

A centralized monitoring and vulcanizing machine technology, which is applied in the direction of overall factory control, overall factory control, program control in sequence/logic controller, etc., can solve the problem that the quality is affected by human factors, the workload of manual recording is heavy, and failures are difficult to find. Reciprocity issues, to achieve the effect of convenient input and modification, reduction of workers' expenses, and reduction of workers' human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

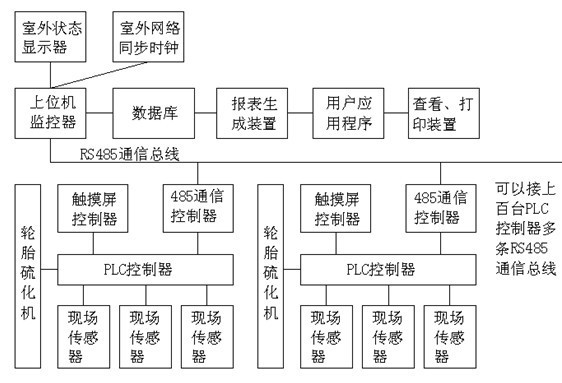

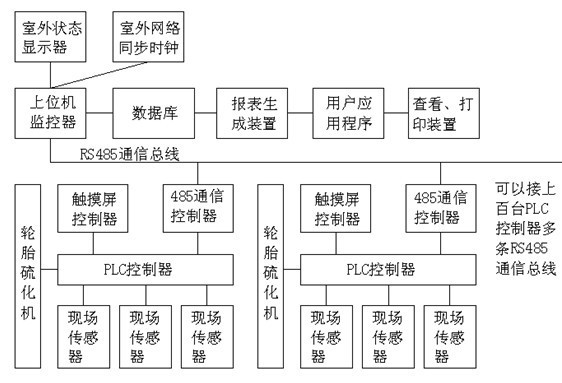

[0033] Embodiment of the present invention: the system is divided into on-site sensor part, PLC acquisition control part, touch screen control display, RS485 communication controller and 485 communication bus part, upper computer monitor, SQLServer2005 database, report generating device, user application program, viewing And printing devices, outdoor status monitors and outdoor network synchronization clocks, etc.

[0034] The functions and implementation methods of each part are introduced as follows:

[0035] Field sensor section.

[0036] The on-site sensor part is responsible for the collection of original data signals on site, which is the basis for the control of the PLC controller, including the external temperature, internal temperature, external pressure, internal pressure, main water pipe temperature, etc. of the vulcanizing machine. sensor.

[0037] PLC acquisition controller part.

[0038] This part is the core of the lower computer of this system. It is respon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com