Double-sided adhesive tape

A tape, double-sided technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve problems such as paste residue, achieve firm bonding, strong adhesion, easy recycling or reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

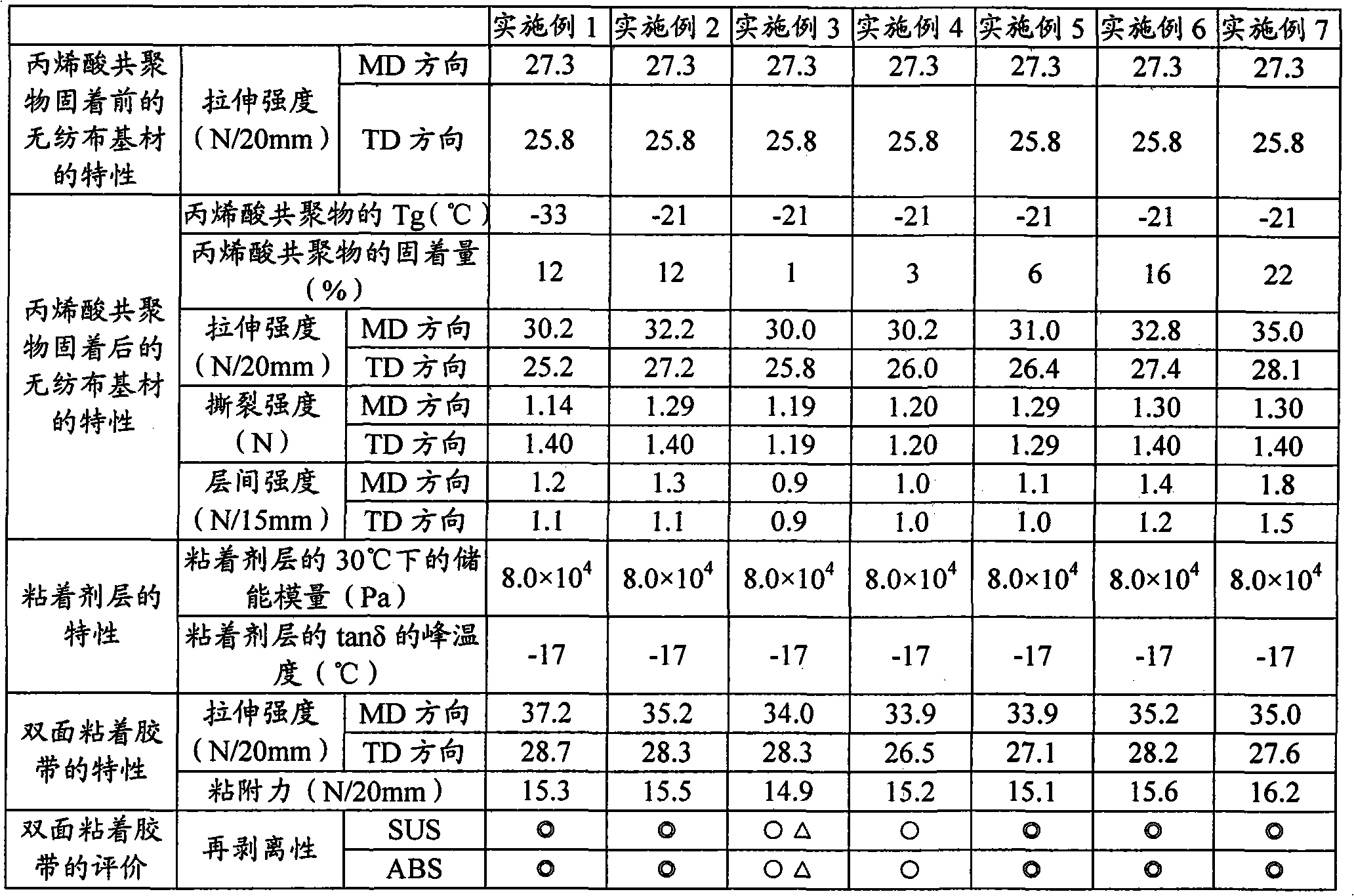

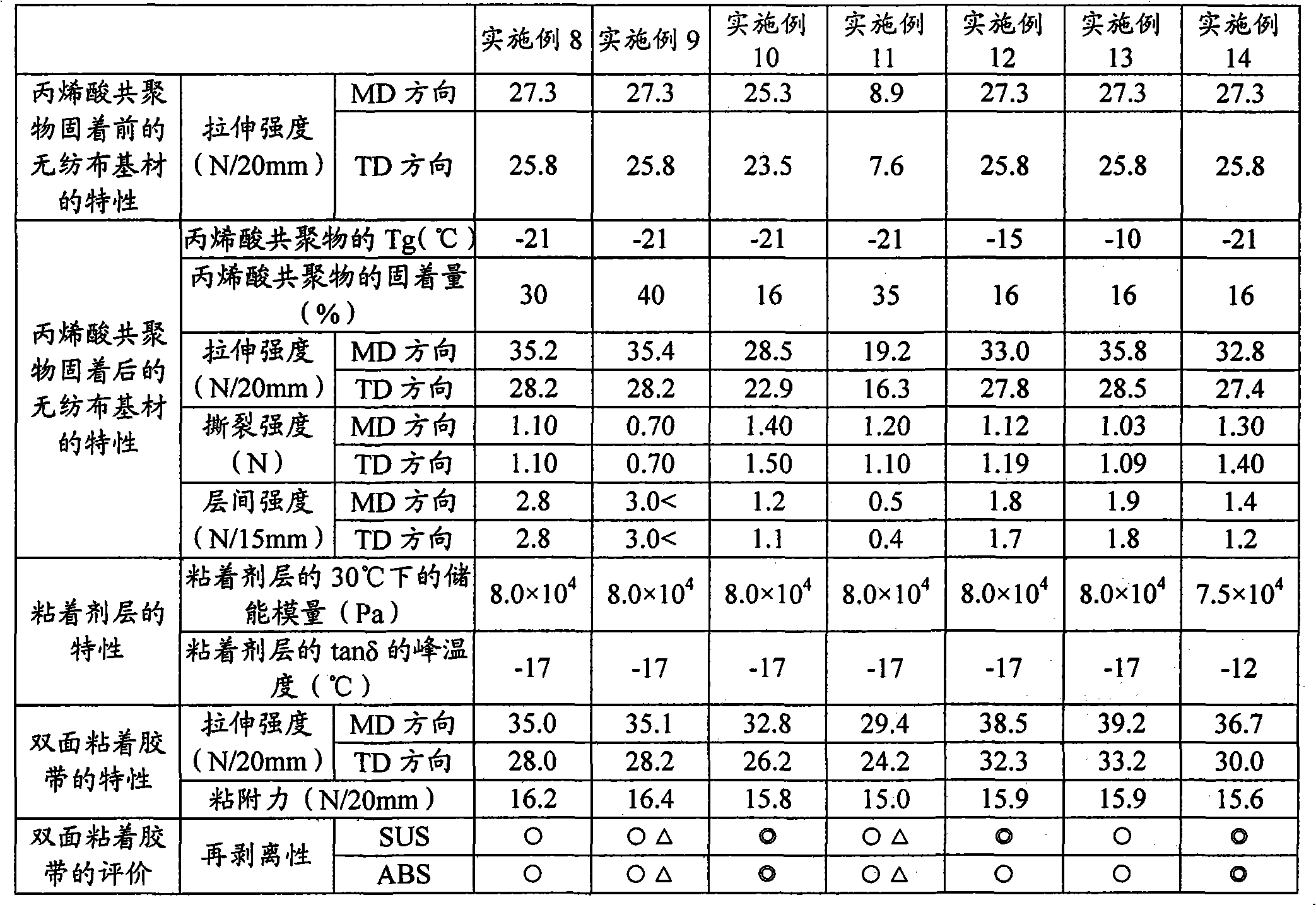

Embodiment 1

[0151] (1) Preparation of non-woven substrate

[0152] A solution containing 100% Manila hemp and 0.5% polyamidoamine epichlorohydrin resin is used to make paper with a weight of 17g / m2 on an inclined short-wire paper machine 2 , Density 0.27g / cm 3 , and a nonwoven fabric substrate having a tensile strength of 27.3 N / 20 mm in the MD direction and 25.8 N / 20 mm in the TD direction was obtained.

[0153] (2) Synthesis of acrylic copolymer fixed to non-woven fabric

[0154] 280 parts of ion-exchanged water was put into the polymerization container equipped with the stirring apparatus, and stirring was carried out sending nitrogen gas, and the temperature inside the reaction container was raised to 80 degreeC. After the temperature was raised, 6 parts of monomer emulsion (1A) having the following composition was added to the reaction container, and then 6 parts of ammonium persulfate and 6 parts of sodium bisulfite were added to initiate polymerization. After maintaining the tem...

Embodiment 2

[0182] A double-sided adhesive tape was prepared in the same manner as in Example 1 except that the acrylic copolymer to be fixed to the nonwoven fabric was an acrylic copolymer obtained in the following production examples.

[0183] 280 parts of ion-exchanged water were added to a polymerization vessel equipped with a stirring device, and the inside of the reaction vessel was heated up to 80° C. while stirring while feeding nitrogen gas. After the temperature was raised, 6 parts of monomer emulsion (1B) having the following composition was added to the reaction container, and then 6 parts of ammonium persulfate and 6 parts of sodium bisulfite were added to initiate polymerization. After maintaining the temperature in the reaction container at 60° C. for 10 minutes, 594 parts of the remaining monomer emulsion (1B) and the following aqueous polymerization initiator solution (2B) were added dropwise to the reaction container at the same time to perform polymerization. The dropwi...

Embodiment 3

[0199] A double-sided adhesive tape was prepared in the same manner as in Example 2 except that the amount of fixation of the acrylic copolymer to the nonwoven fabric base material was 1% with respect to the mass of the nonwoven fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com