Coating film peeling apparatus for resin material

A resin material and peeling device technology, applied in plastic recycling, household components, applications, etc., can solve the problems of excessive cutting of recycled materials and deterioration of recovery rate, and achieve the effect of simplifying processing, improving recovery rate and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

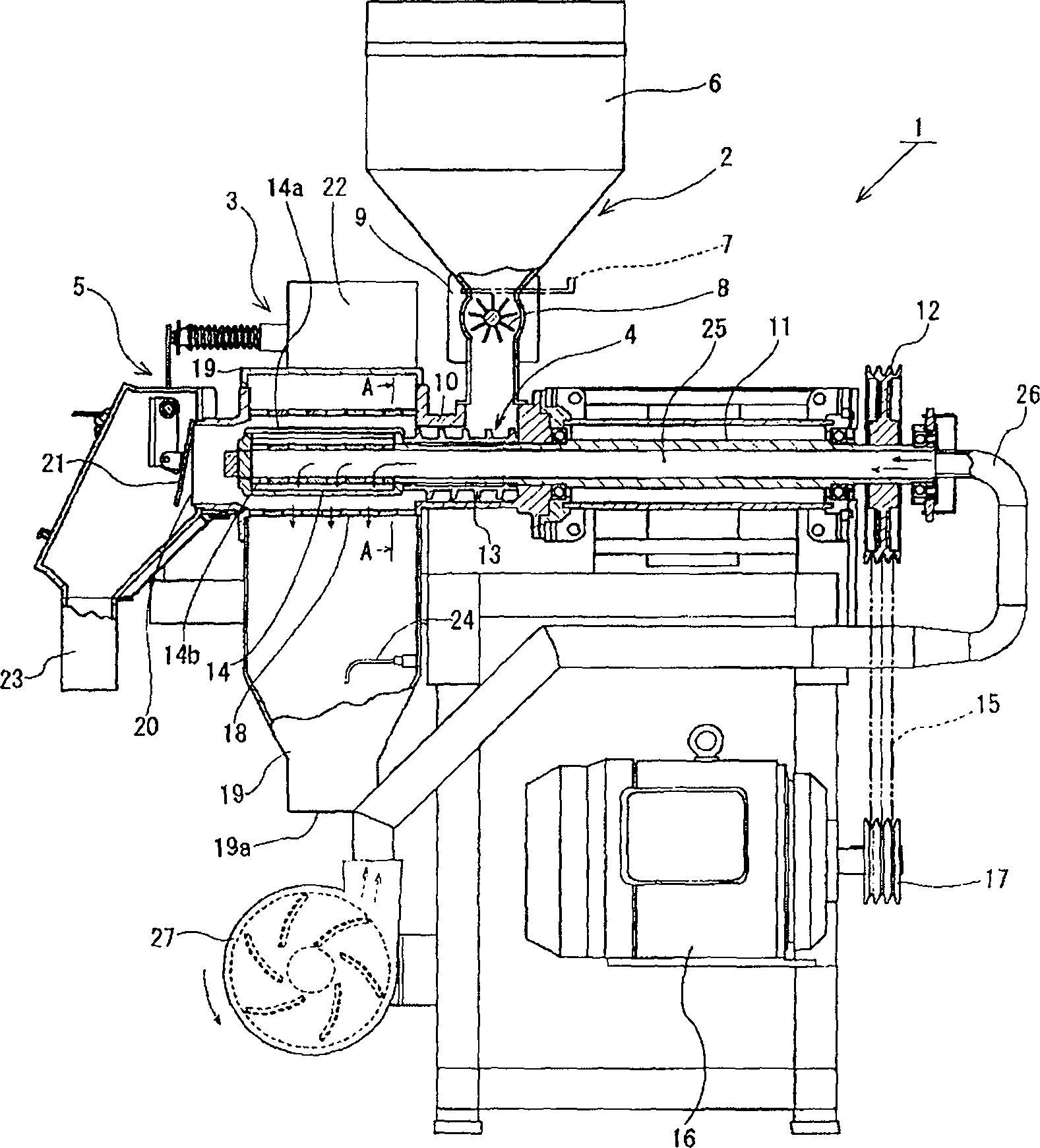

[0039] As a coating stripping device, a figure 1 The device shown is the pulverized material introduction part 2, the coating film peeling part 3, the pulverized material feeding part 4 and the pulverized material discharge part 5.

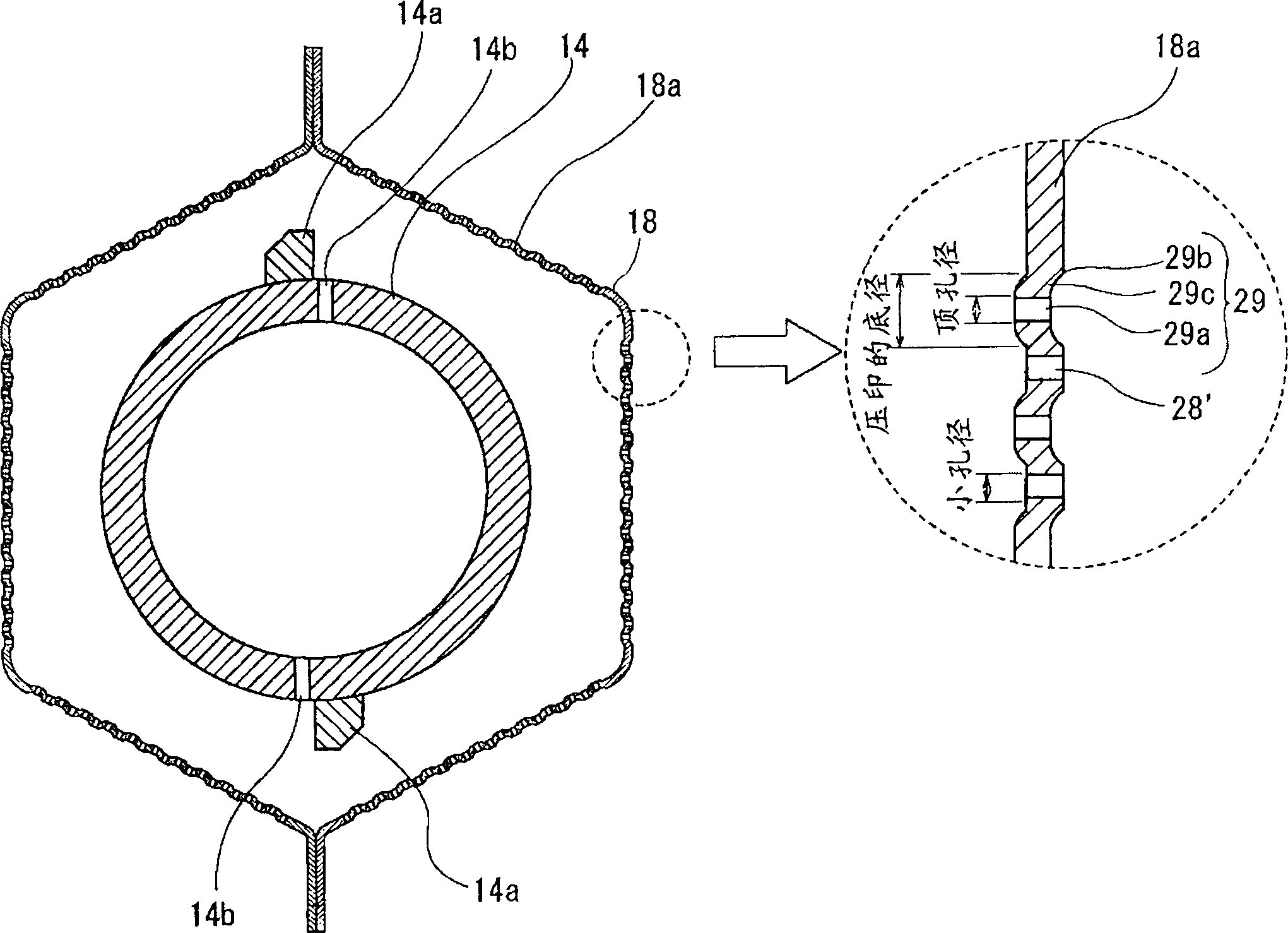

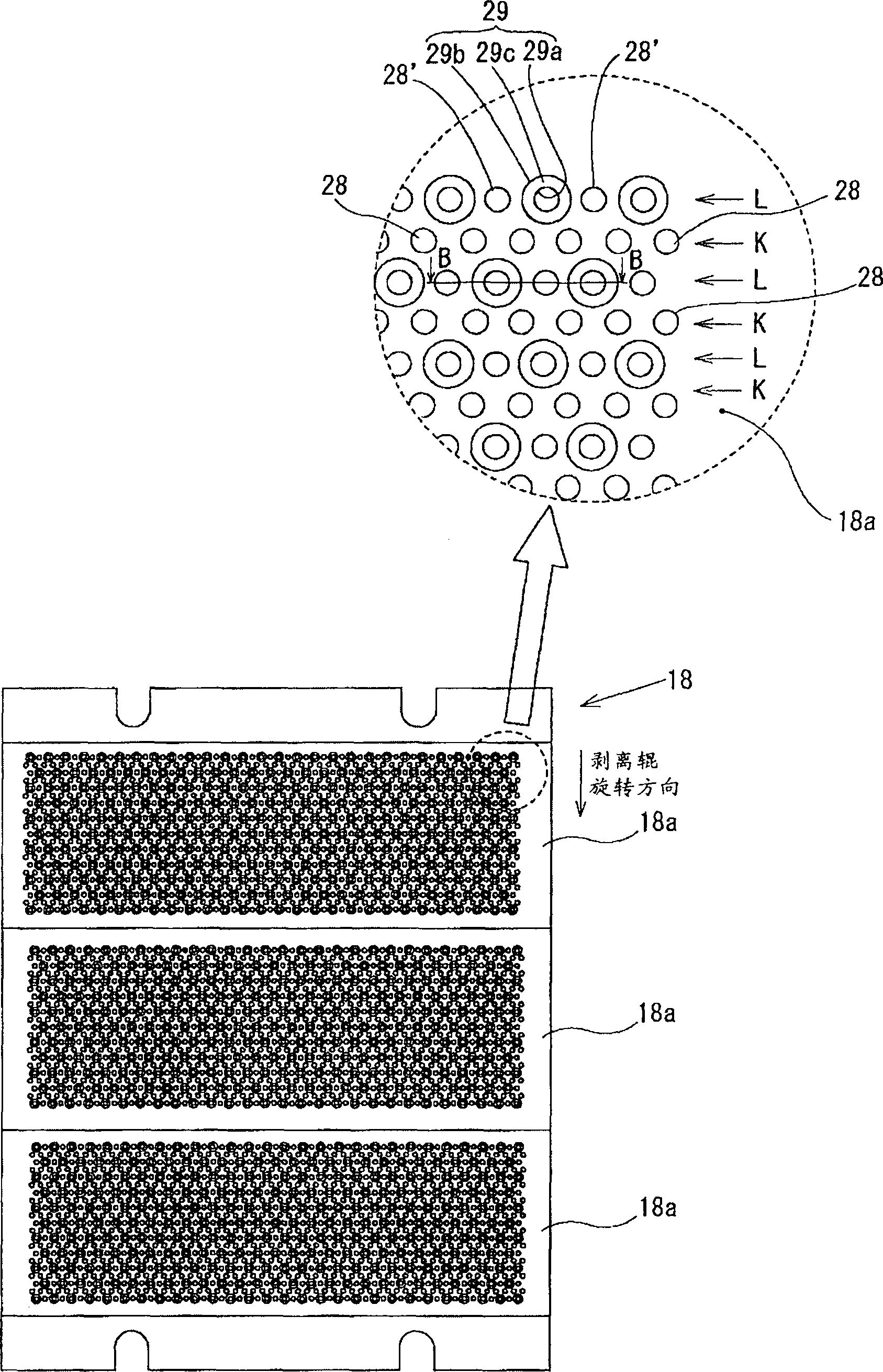

[0040] Coating film peeling part 3 uses such as figure 2 and image 3 In the shown hexagonal square cylindrical body 18, the shape of the coating film passage hole is such that the small hole row K and the small hole protruding ring row L are alternately arranged in multiple rows on the mesh plate 18a with a thickness of about 2 mm. The structure on one side of the rotation direction of the above-mentioned peeling roller; the small hole row K is provided with punching small holes 28 with a diameter of about 2mm in a horizontal row at a predetermined interval; On different rows, circular protruding rings 29 composed of a top hole 29a with a diameter of about 2mm and a convex embossing portion 29b with a diameter of about 4mm centered on the top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com