Heavy-duty rail motor car

A rail car and heavy-duty technology, which is applied in the direction of transport passenger cars, transport passenger cars, electric vehicles, etc., can solve the problem that rail cars cannot adapt to the special environmental requirements of high-cold and high-altitude areas, and achieve good living conditions and safety guarantees, fast speed, and easy operation Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

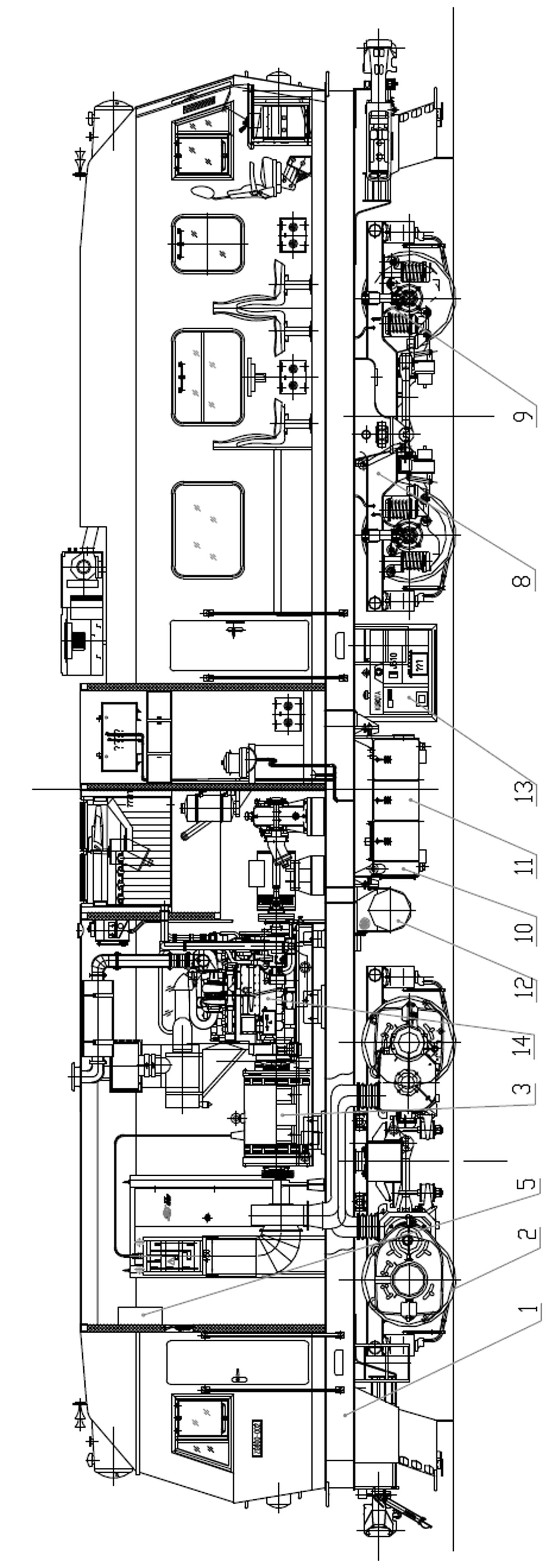

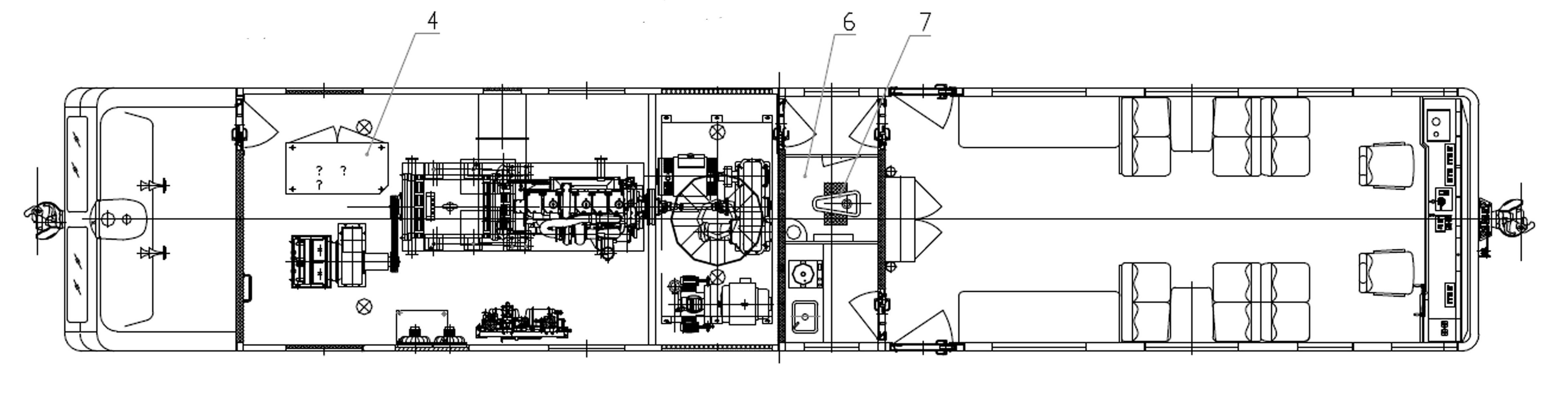

[0009] A kind of heavy-duty railcar according to the present invention comprises a car body 1, a wheel set 2, a transmission system 3 located inside the car body 1, a main traction generator, a main diesel generator set and a control system 4, and the transmission system 3 adopts an AC - DC transmission device, the control system 4 adopts microcomputer constant power excitation device and PLC programmable controller, and the main traction generator adopts power frequency power generation device and supporting power supply device. The main traction generator can provide 160kVA, 400V, 50Hz three-phase AC power for construction machinery and coupled vehicles.

[0010] The side wall of the inner corridor on one side of the rail vehicle system carries a fully welded steel structure, and the driver's cab at both ends. Absorbing the design concept of the passenger car, the car is equipped with a kitchen, lounge and toilet, providing comfortable living conditions for the drivers and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com