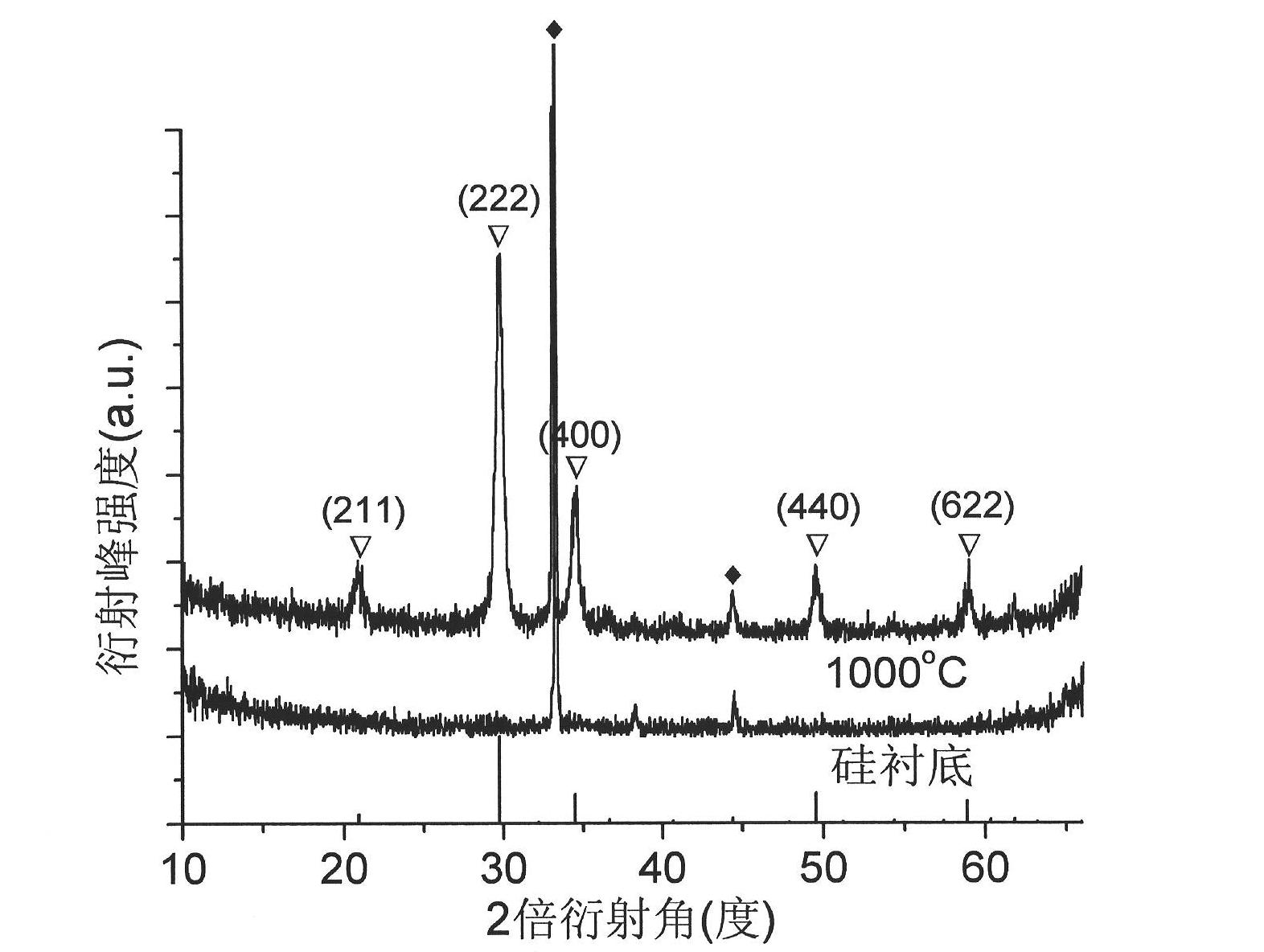

Method for improving luminescence decay of Eu3+ ion doped Lu2O3 film

A technology of luminescence attenuation and ion doping, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of low solubility and precipitation of alkoxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Eu by sol-gel method combined with spin-coating process 3+ / Pr 3+ co-doped Lu 2 o 3 film. Use LuCl 3 ·6H 2 O as a precursor. 5g LuCl 3 ·6H 2 O powder was added into 50ml of absolute ethanol, and stirred at 100°C for 2h to completely dissolve the powder to obtain a transparent solution. Thereafter, 2 g of polyethylene glycol (molecular weight 6000), 6 g of citric acid and 6 ml of water were added and stirred at room temperature for 2 h to obtain a transparent sol. According to the concentration requirement, add 0.7ml Eu(NO 3 ) 3 solution (0.916mol / L) and the desired co-doped amount of Pr(NO 3 ) 3 Solution to sol, co-doped with Pr 3+ Concentrations are 0.1mol%, 0.3mol%, 0.5mol% Pr 3+ , the desired precursor sol can be obtained after stirring for about half an hour.

[0022] Si single wafers used to grow thin films need to be immersed in a mixture of concentrated sulfuric acid and concentrated phosphoric acid (volume ratio 3:1), rinsed with hydrofluoric acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com