Steel tube arched concrete dam and construction method

A technology of concrete-filled steel tube arches and concrete-filled steel tubes, applied in arch dams, dams, etc., can solve problems such as large material consumption, large amount of hydration heat, and structural temperature cracks, so as to reduce the cross section of the arch dam, reduce the heat of hydration, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

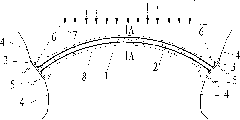

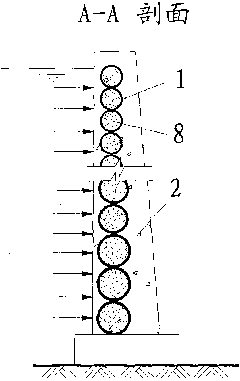

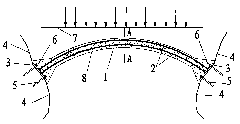

[0017] refer to figure 1 , figure 2 , the present invention consists of a number of arched steel pipes 1 superimposed to form an arch dam. Ventilation holes are left in the middle of the arched steel pipes. Concrete 7 is poured in the arched steel pipes. 4. Anchored by anchor bolts 5, a concrete protective layer 2 is poured around the steel pipe, and the anchorage between the arched steel pipe and the rock is enclosed by concrete 6, 7 is the water facing surface.

[0018] The construction method of steel pipe concrete arch dam: it is characterized in that comprising the following steps:

[0019] 1. The steel pipe is prefabricated by the factory, and a section does not exceed 12 meters, which is convenient for transportation;

[0020] 2. The entire arch is welded at the construction site, and then hoisted to the bottom plane of the dam to form the first steel pipe arch. If the dam is too wide, it can be hoisted in sections, and the steel pipes are connected by welding;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com