Node connection device for self-centering prestressed concrete frame

A node connection and prestressing technology, applied in building components, earthquake resistance, construction, etc., to reduce residual deformation, reduce column section size, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

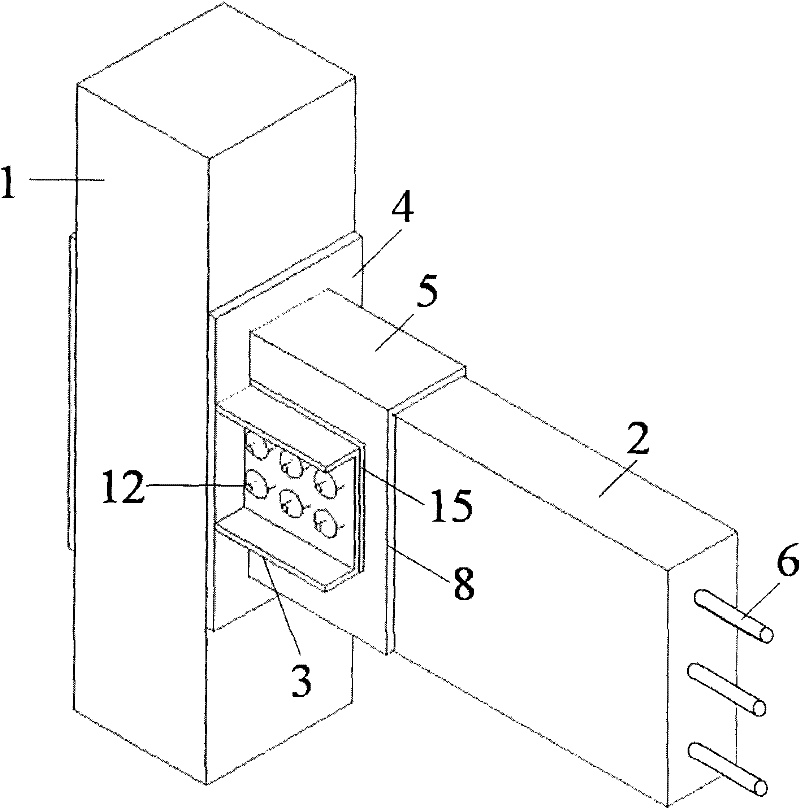

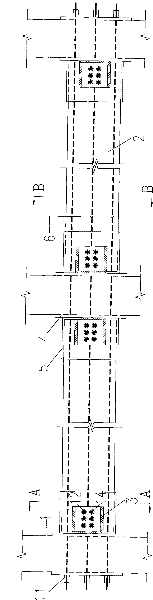

[0026] The node connection device of the self-centering prestressed concrete frame of the present invention is mainly composed of two parts, the embedded steel parts of beams and columns and the frictional energy dissipation device.

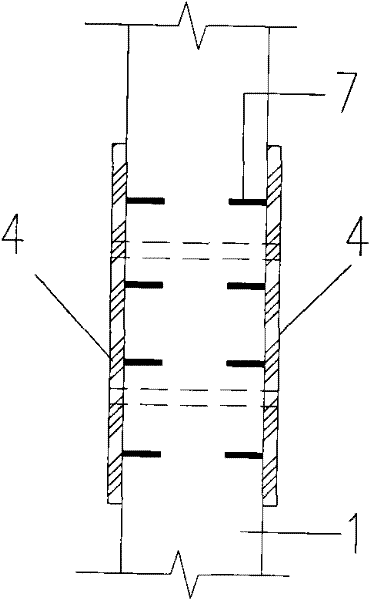

[0027] The beam-column pre-embedded steel parts mainly include column-end reinforced steel plates 4, beam-end reinforced steel plates 5, and shear studs 7. Spiral hoops 9 may also be added to the ends of prefabricated beams. The reinforced steel plate 4 at the end of the column and the reinforced steel plate 5 at the end of the beam are used to improve the local compressive capacity of the reinforced concrete. It is used to provide constraints to the concrete at the end of the beam and improve the local pressure bearing capacity of the concrete. The above-mentioned steel parts are prefabricated together with the prefabricated concrete column 1 and the prefabricated concrete beam 2 in the factory.

[0028] The frictional energy-dissipating parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com