Starting device for enriching-valve type carburetor

A technology of starting device and enrichment valve, which is applied in the direction of carburetor, machine/engine, charging system, etc., can solve the problems of mixed gas becoming rich, mixed gas too rich, complex manufacturing, etc., to reduce production costs, simplify The effect of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

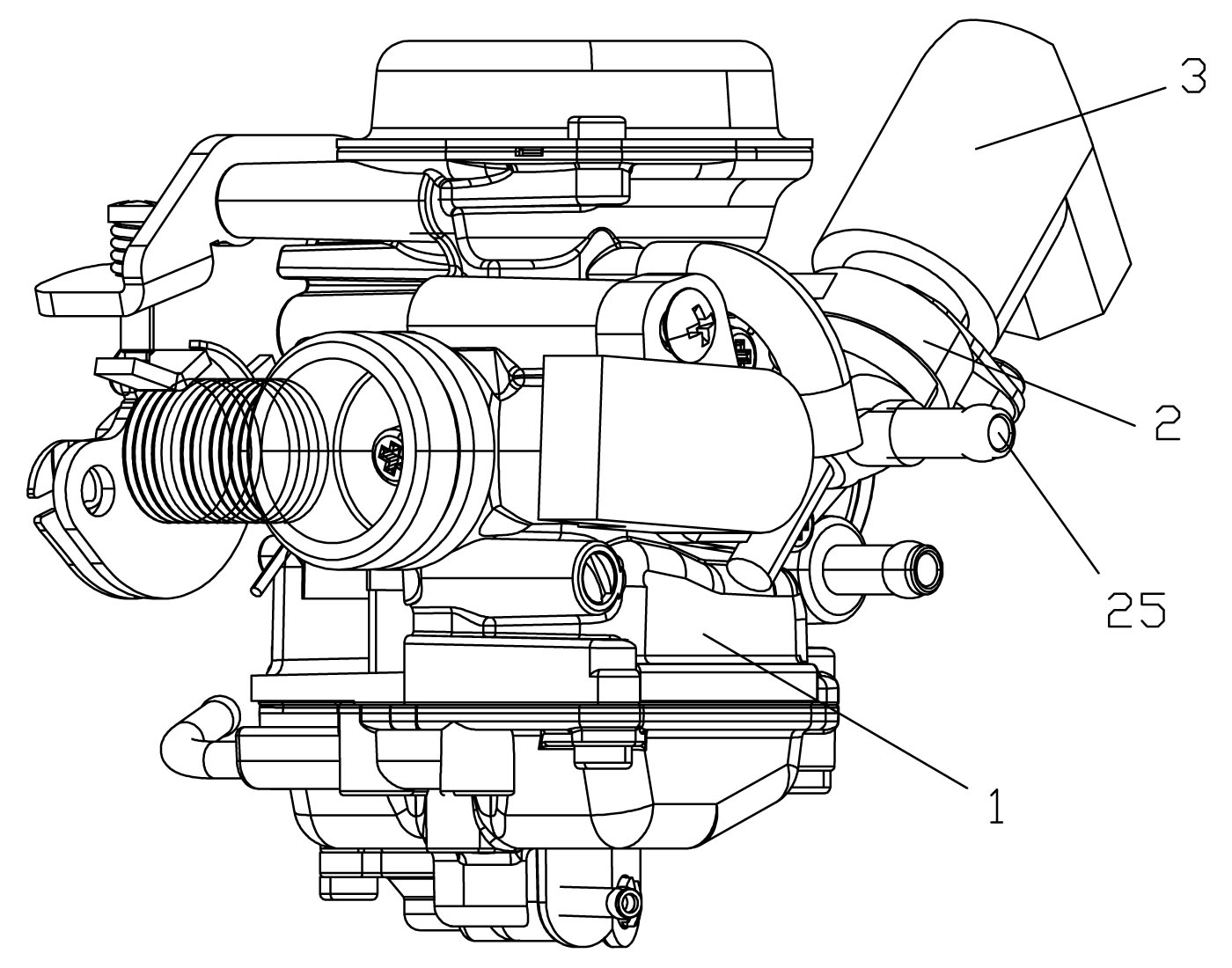

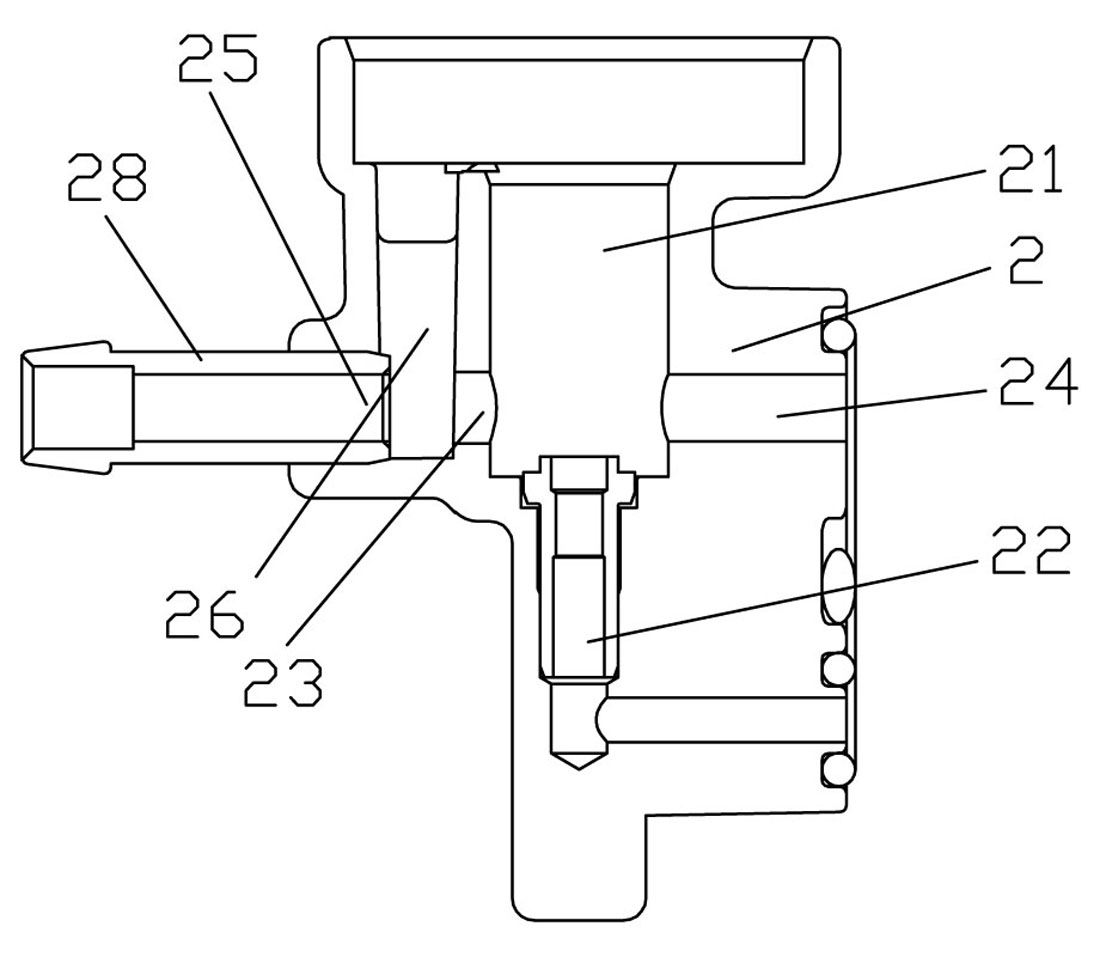

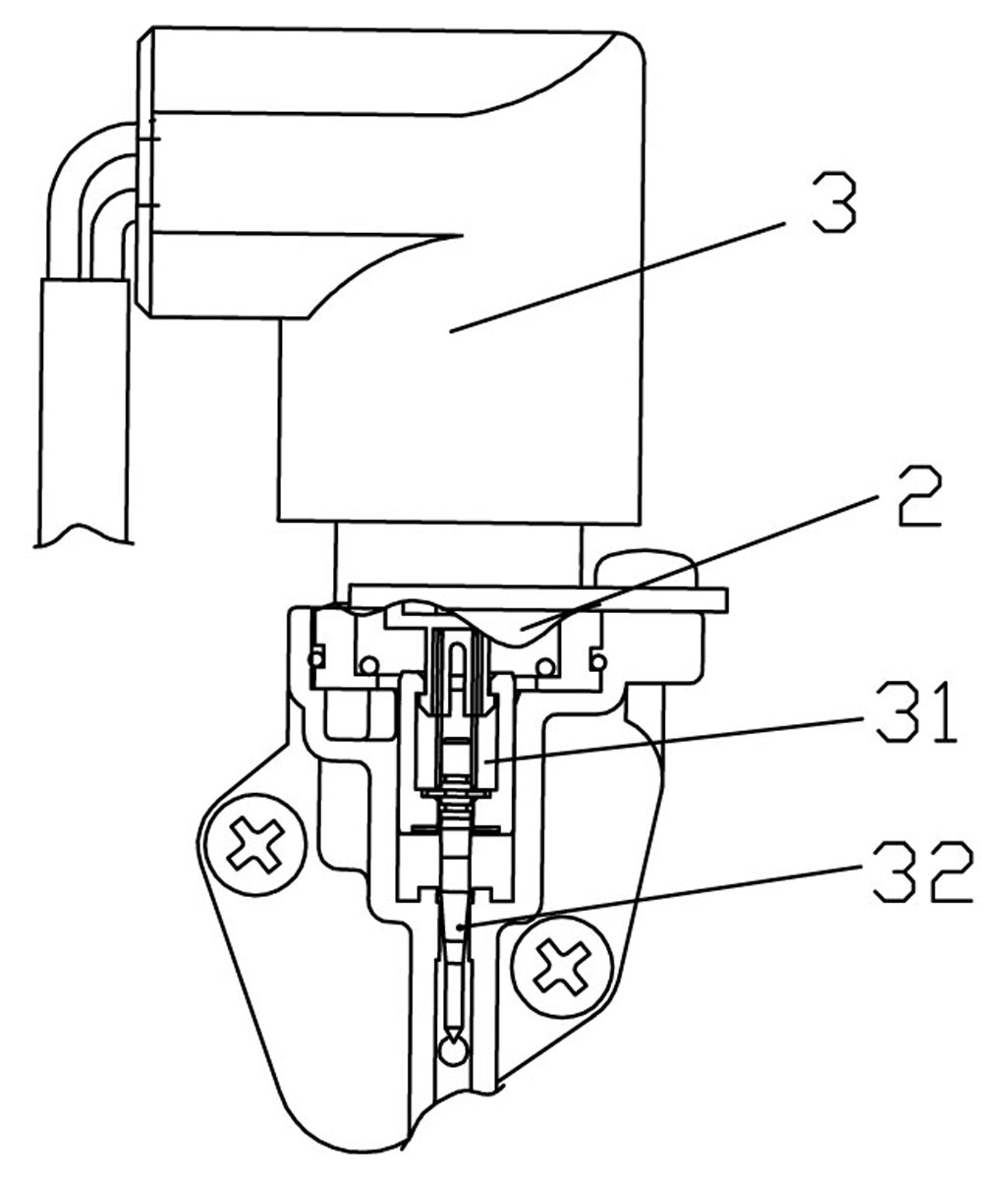

[0026] refer to figure 1 , figure 2 , image 3 , a starting device for an enrichment valve type carburetor, comprising an enrichment valve body 2 arranged on a carburetor body 1, a control valve 3 is mounted on the enrichment valve body 2, and the control valve 3 is preferably an electronic valve Of course, it can also be a mechanical valve, which is provided with a starting plunger 31 and an oil needle 32, and the starting plunger 31 and the oil needle 32 are respectively inserted into the plunger cavity 21 of the enrichment valve body 2 and the enrichment oil supply channel 22 and can move along its axis, the plunger cavity 21 is provided with an air inlet 23 and a mixed gas outlet 24, the air inlet 23 is directly communicated with the atmosphere through a channel other than the engine air intake system, and the engine inlet The gas system consists of carburetor, engine intake, engine intake branch pipe and air filter assembly, etc. This design makes it unnecessary to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com