Intelligently-annealing power source control device

A technology of a power control device and a power control unit, which is applied to output power conversion devices, electrical components, manufacturing tools, etc., can solve the problems of high cost, unstable output, low precision, etc., achieve perfect functions, improve accuracy, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

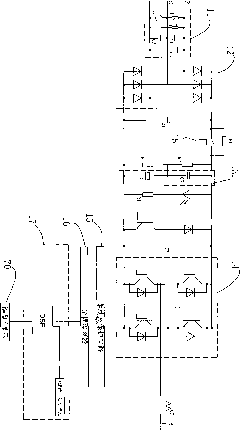

[0018] Below in conjunction with accompanying drawing, the present invention is described in detail:

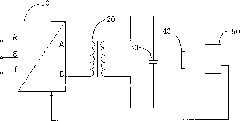

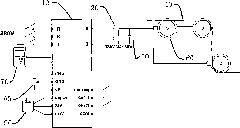

[0019] The invention provides a power control device for intelligent annealing, such as figure 1 , 2 As shown, it includes an annealing power supply control unit 10 that is connected to a three-phase alternating current power supply and converts the three-phase alternating current into a single-phase alternating current, a transformer 20 connected to the output end of the annealing power supply control unit 10, and a capacitor 30 connected to the transformer 20, with An auxiliary unit 40 with a conductive wheel 60 and a voltage feedback card 50 forming a loop with the annealing power supply control unit.

[0020] Annealing is a metal heat treatment process that heats the metal to a certain temperature for a period of time, so that its various indicators can reach the standard. According to the law of energy conservation, it is known that to make the resistance generate heat,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com