Microwave plasma generating devices and plasma torches

A technology of plasma and equipment, which is applied in the field of plasma equipment, can solve problems such as difficult to achieve impedance matching, and achieve the effects of optimizing VHF power transfer, easy impedance matching, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

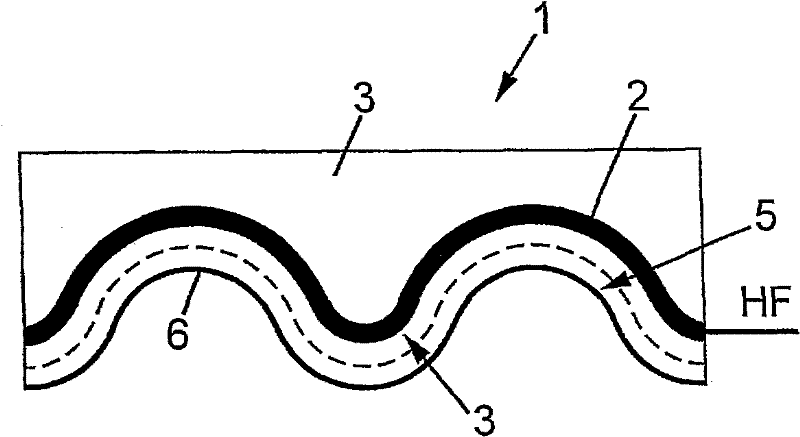

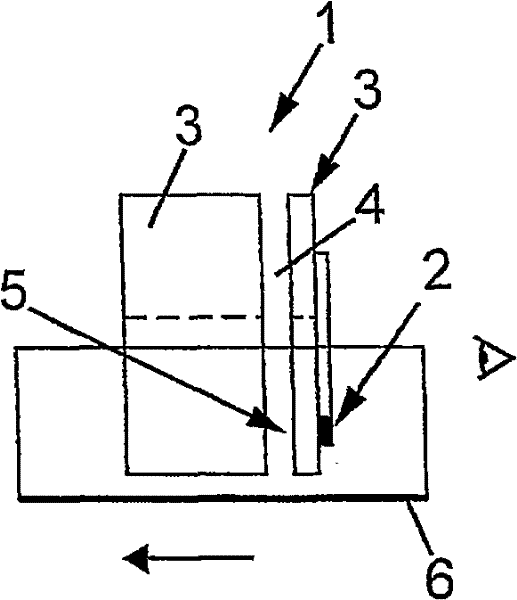

[0086] Figure 1a with 1b A device 1 according to the invention is schematically illustrated in which a microstrip 2 with a curved shaped face is connected to a very high frequency generator. The microstrip 2 is fixed to the surface of a dielectric support 3, one edge of which supports 3 coincides with a curved edge of the microstrip. A slot 4 is provided in the dielectric, gas is injected into the slot 4 , and a plasma 5 is generated in the slot 4 . The substrate 6 to be processed is averagely perpendicular to the face of the microstrip and has a warped shape matching the curvature of the dielectric and the microstrip, and the substrate 6 is driven under the device in the direction indicated by the arrow. According to this embodiment, the substrate is perpendicular to the microstrips and the treatment is a post-discharge plasma treatment.

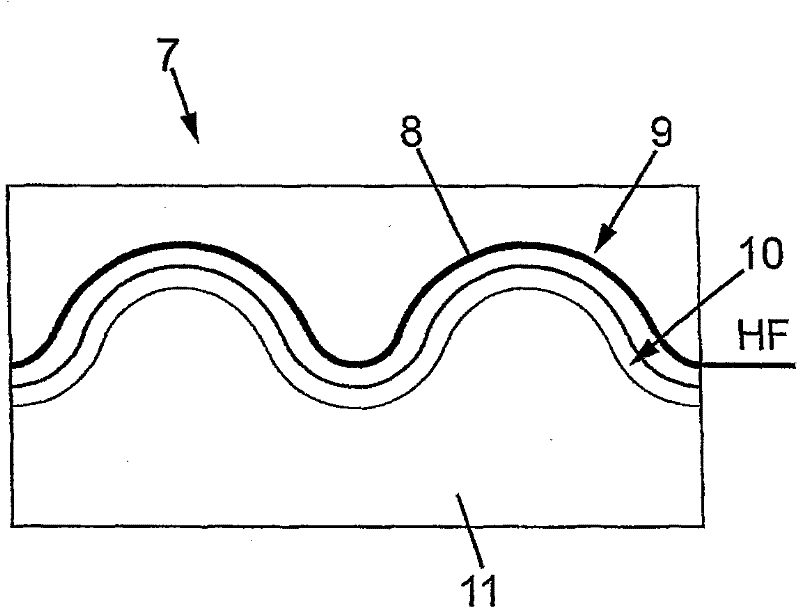

[0087] Figure 2a with 2b A device 7 according to the invention is schematically illustrated in which a warp-shaped microstrip 8 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com