Sound velocity gradient flexible gel material with broadband adjustable parameters and preparation method of sound velocity gradient flexible gel material

A gel material and parameter technology, applied in the direction of coating, etc., can solve the problems that the artificial devices with rigid characteristics are difficult to achieve broadband adjustment, limit the transmission efficiency of acoustic wave energy, and the performance of artificial devices is limited, so as to achieve good swelling resistance and acoustic performance Maintain stable, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention provides a preparation method of a sound velocity gradient flexible gel material with broadband adjustable parameters, comprising the following steps:

[0033] S1, adding glycerin to the polymer compound monomer solution, stirring uniformly, then adding an initiator and a crosslinking agent, stirring uniformly, and obtaining a precursor solution after defoaming.

[0034] S2, curing the precursor solution to obtain a gel material.

[0035] S3, uniformly smearing the silicone elastomer solution on the surface of the gel material, and after solidifying again, obtains the flexible gel material with a sound velocity gradient with a wide-band adjustable parameter.

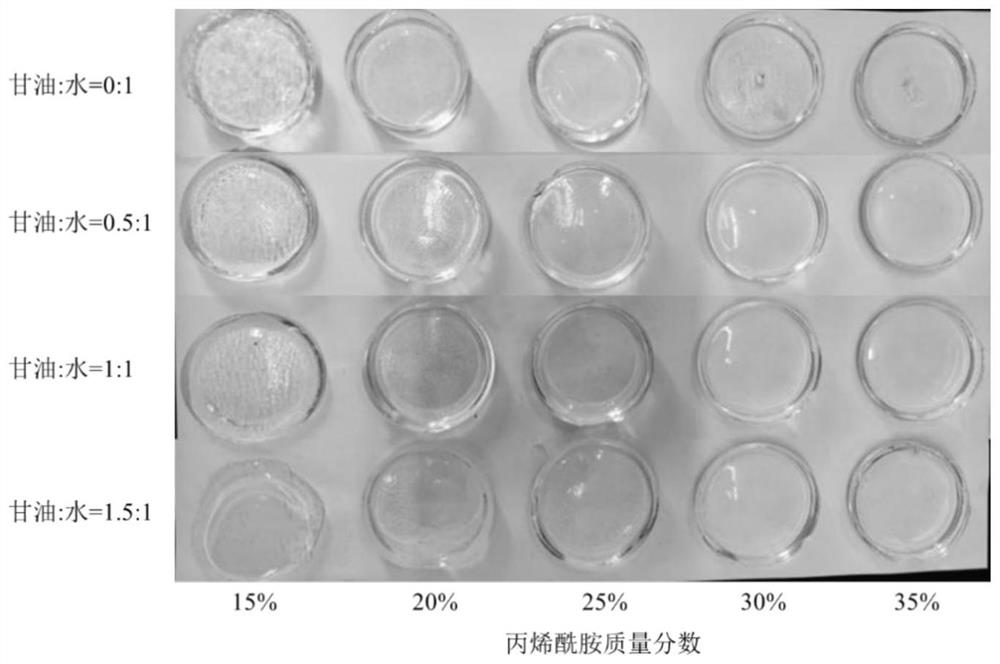

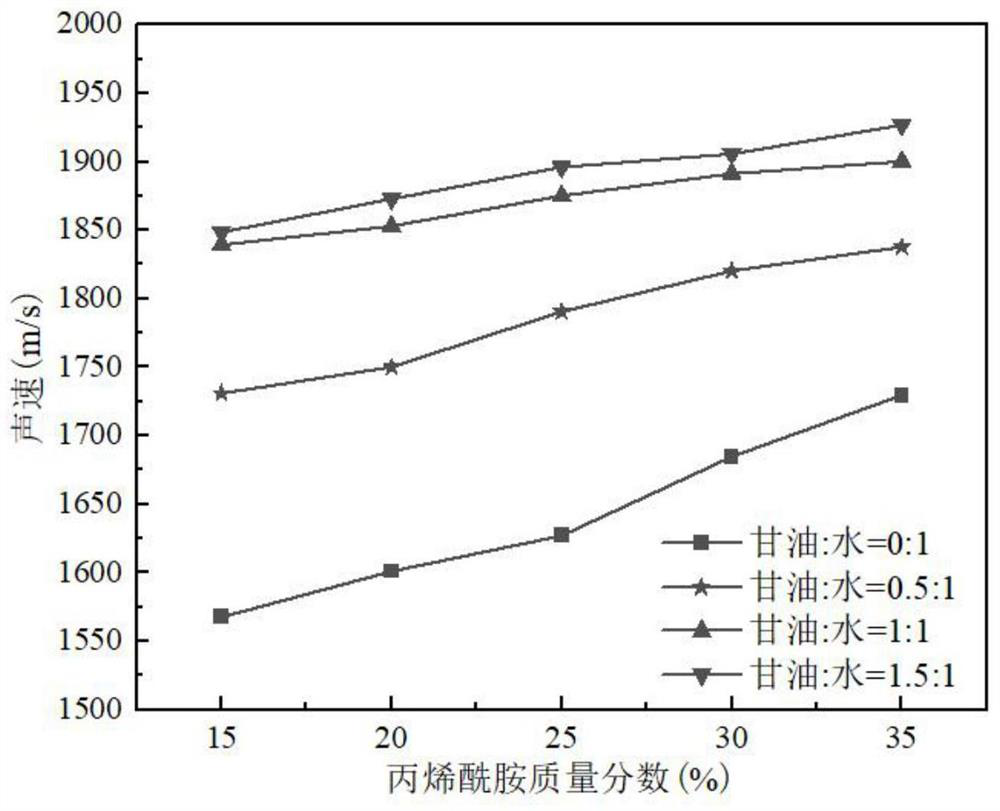

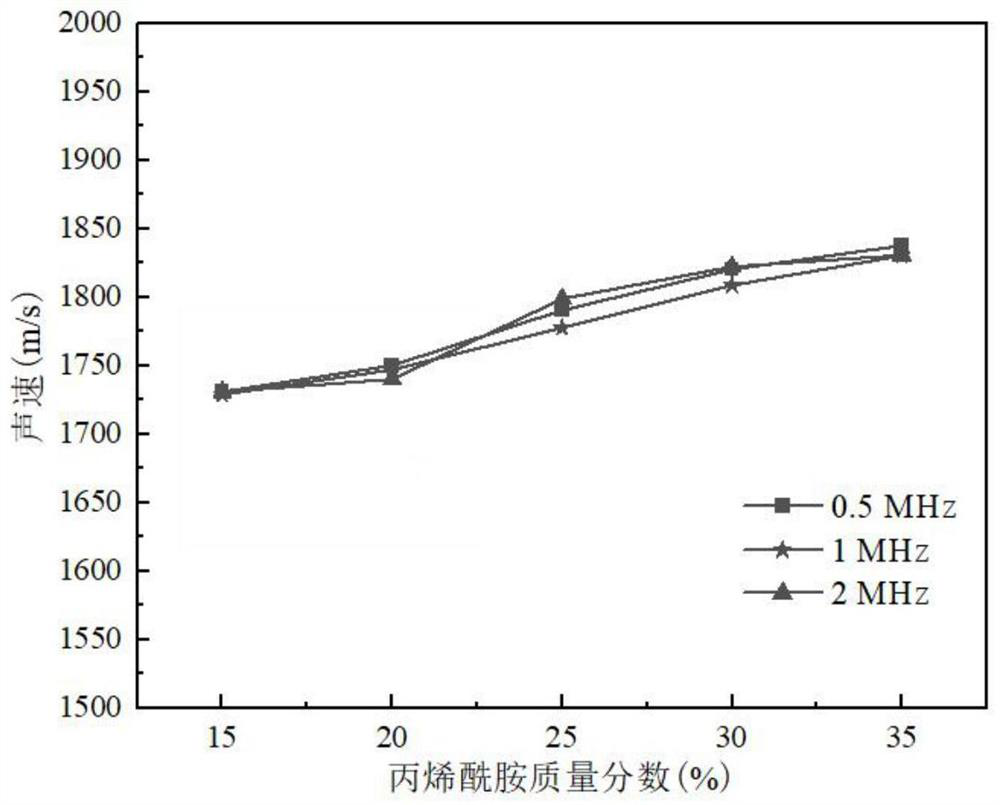

[0036] In the embodiment of the present invention, the polymer compound is used to form a non-covalent cross-linked network as a gel matrix to realize the transition from liquid to flexible solid. By changing the concentration of polymer compound monomers and changing the c...

Embodiment 1

[0048] This embodiment provides a method for preparing an acoustic gradient flexible gel material with broadband adjustable parameters. The steps are as follows:

[0049] S1. Prepare an aqueous solution of acrylamide with monomer mass fractions of 15%, 20%, 25%, 30%, and 35% respectively, and stir and mix evenly to obtain a monomer solution.

[0050] S2, adding glycerol to the monomer solution, the mass ratio of the glycerol to the water in step S1 is 0.5:1, respectively, and stirring uniformly to obtain a first mixed solution.

[0051] S3, adding 0.4% potassium persulfate and N,N'-methylenebisacrylamide of the same mass relative to the mass fraction of acrylamide monomer into the first mixed solution, stirring and mixing uniformly to obtain a second mixed solution.

[0052] S4. The second mixed solution is placed in an ultrasonic cleaning machine and a vacuum box in turn to completely remove foam to obtain a precursor solution.

[0053] S5. The precursor solution is placed i...

Embodiment 2

[0057] This embodiment provides a method for preparing an acoustic gradient flexible gel material with broadband adjustable parameters. The steps are as follows:

[0058] S1. Prepare an aqueous solution of acrylamide with monomer mass fractions of 15%, 20%, 25%, 30%, and 35% respectively, and stir and mix evenly to obtain a monomer solution.

[0059] S2, adding glycerol to the monomer solution, the mass ratio of the glycerol to the water in step S1 is 1:1 respectively, and stirring uniformly to obtain a first mixed solution.

[0060] S3, adding 0.4% potassium persulfate and N,N'-methylenebisacrylamide of the same mass relative to the mass fraction of acrylamide monomer into the first mixed solution, stirring and mixing uniformly to obtain a second mixed solution.

[0061] S4. The second mixed solution is placed in an ultrasonic cleaning machine and a vacuum box in turn to completely remove foam to obtain a precursor solution.

[0062] S5. The precursor solution is placed in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com