Electric cleaning device of dirty belt of post insulator of DC converter station

A technology for post insulators and DC converter stations, applied in cleaning methods and appliances, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems such as high labor intensity, difficult operation, human hazards, etc., and achieve convenient movement and maintenance, to ensure the lifting height and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

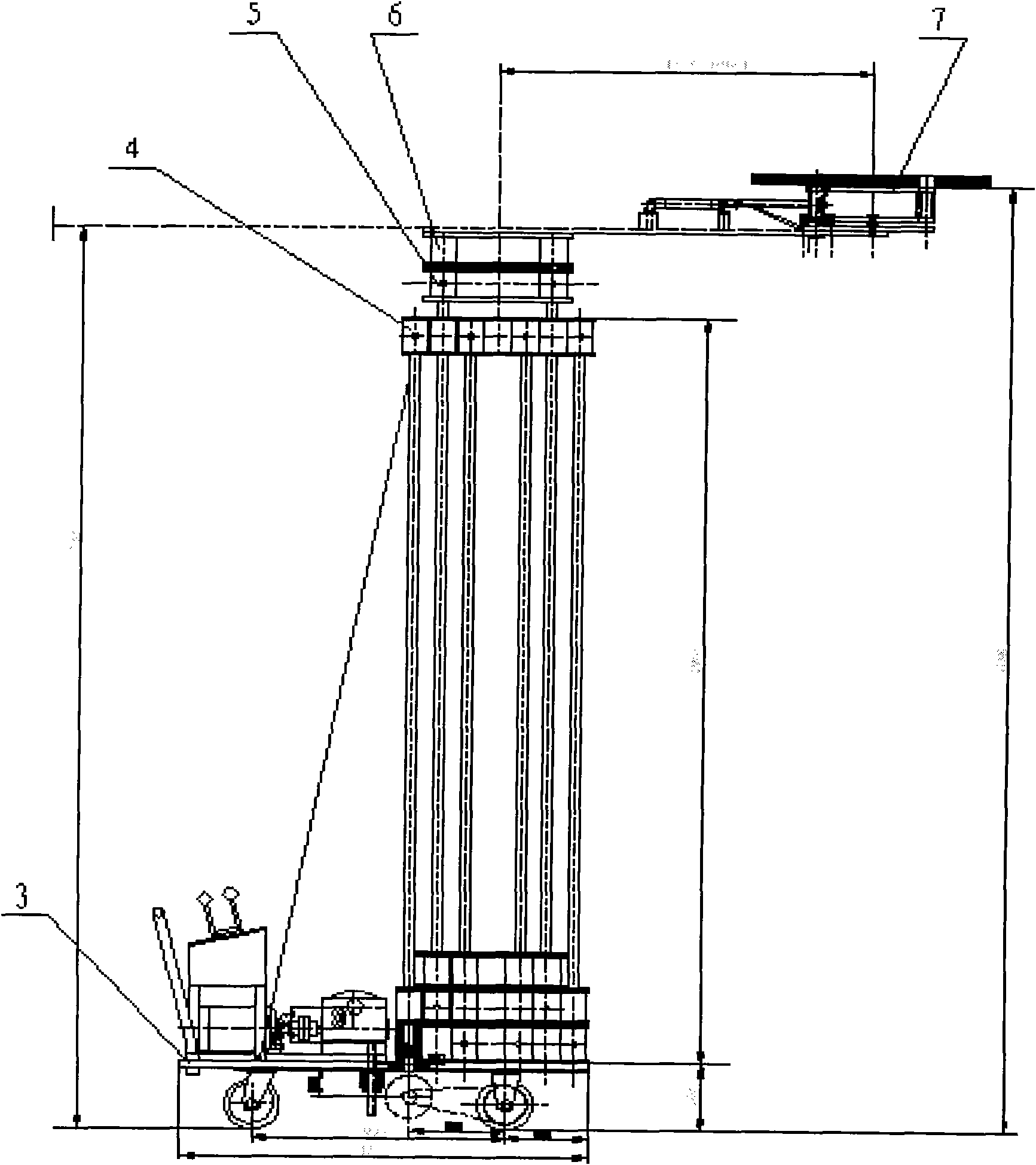

[0030] figure 1 Instructions marked in: 3-Trolley, 4-Chassis, 5-Secondary insulation frame, 6-Three-level insulation frame, 7-Pneumatic arm.

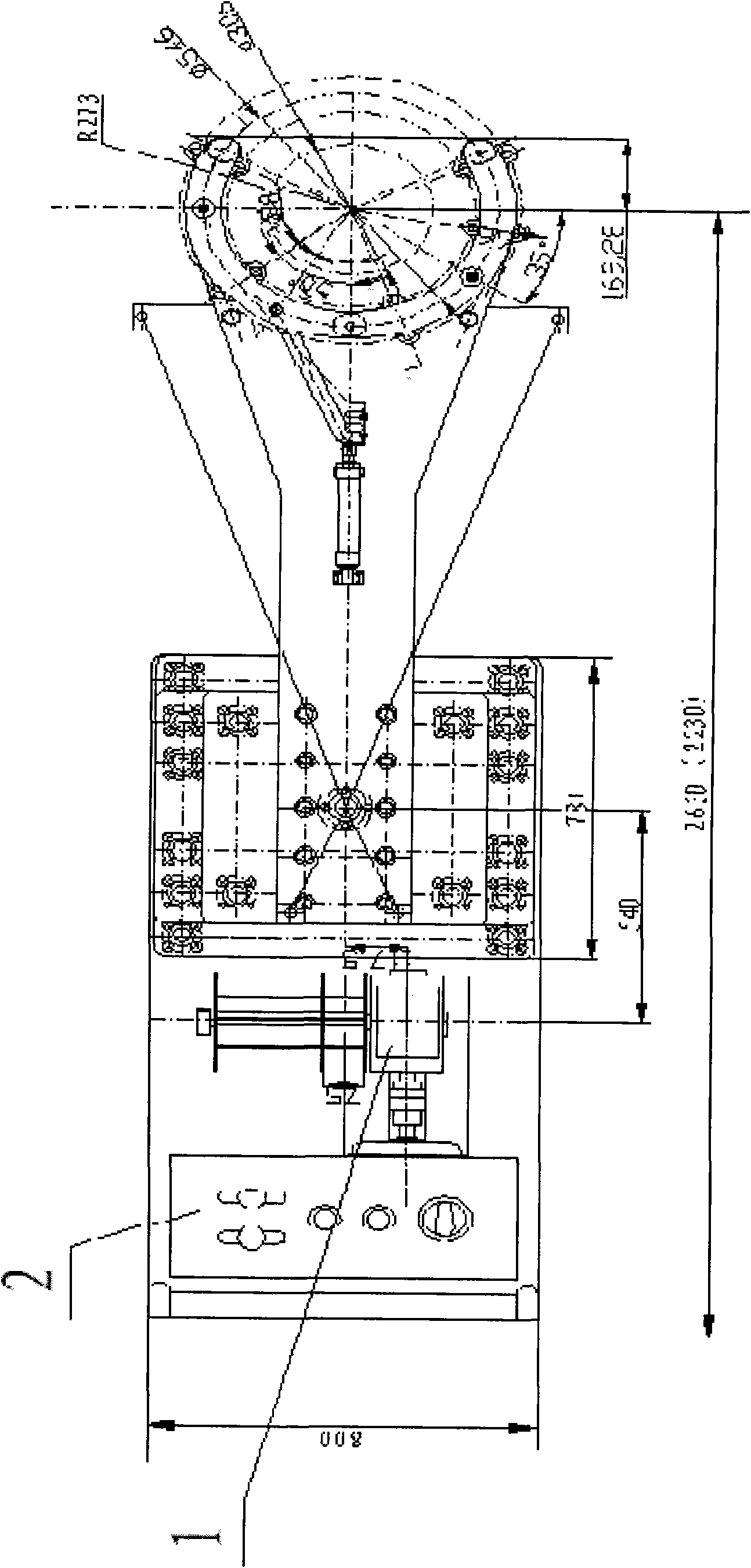

[0031] figure 2 Instructions marked in: 1-reducer, 2-gas and electric operation console.

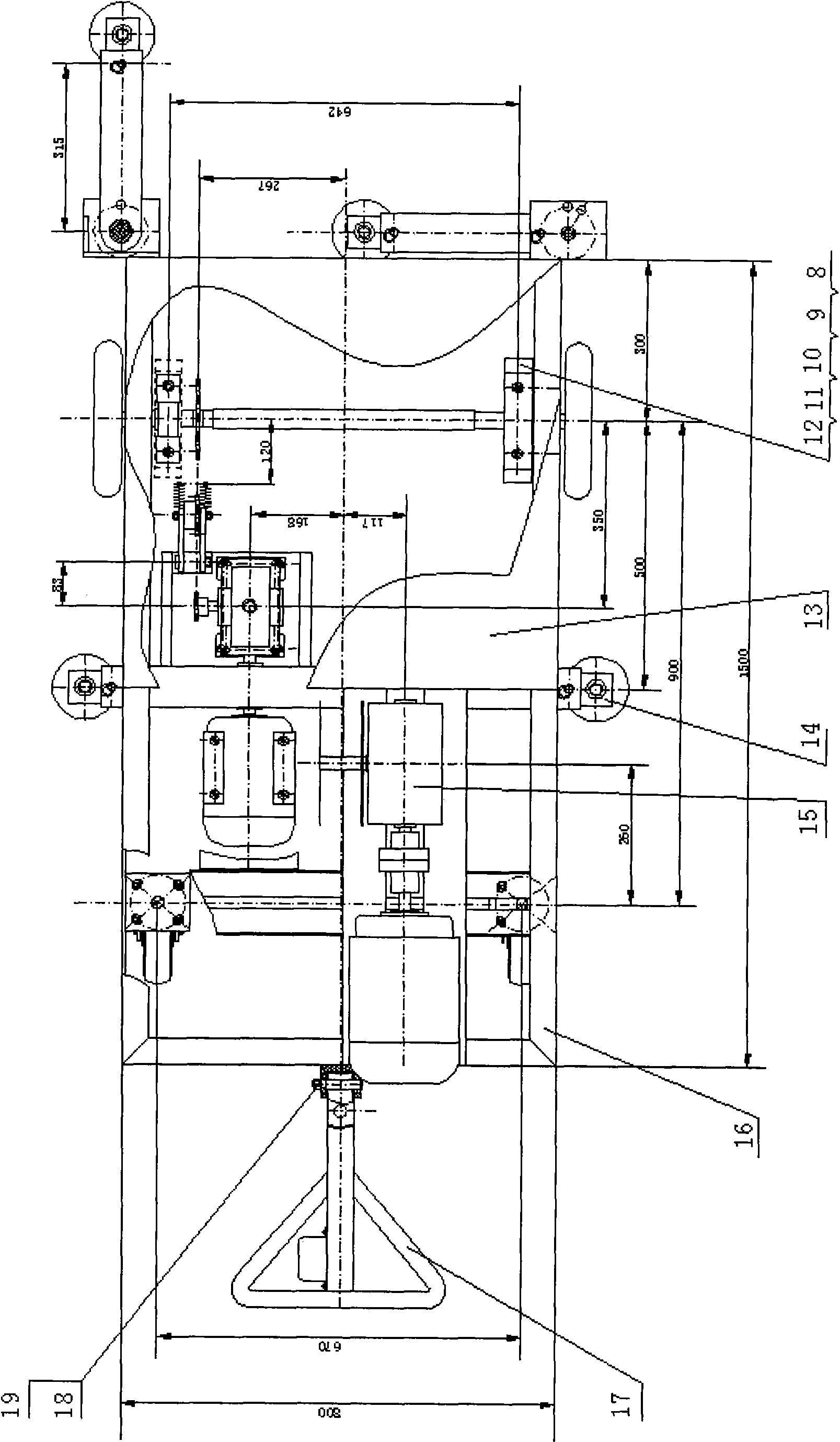

[0032] image 3 Explanation of the middle mark: 8-outer spherical ball bearing with seat, 9-hexagon head bolt M12×35, 10-hexagon nut M12, 11-driven wheel shaft, 12-sprocket 1, 13-welding of trolley bottom plate, 14- Side telescopic arm, 15-power reducer assembly, 16-car chassis welding, 17-steering arm welding, 18-control arm pin, 19-hex nut M12.

[0033] Figure 4 Instructions marked in: 20-tension spring (16×280), 21-universal wheel 200×50, 22-traveling machine (including 4-M8×30 bolts and nuts), 23-tension sprocket (including 6002z bearing / 2), 24- Tensioner tension spring (16×150 / 2), 25-Plywood, 26-Sprocket shaft (including 2-M10 nut and 2-φ15 shaft clamp spring), 27-Lock 2 (including M10 One piece of nut), 28-08B type roller chain, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com