Hydrocylinder-type anti-rolling system used for crane

A hydraulic cylinder and crane technology, applied in the field of hydraulic cylinder type anti-rolling system, can solve the problems of poor reliability, unresponsiveness, slow swing attenuation, etc., and achieve the effects of fast alignment, low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

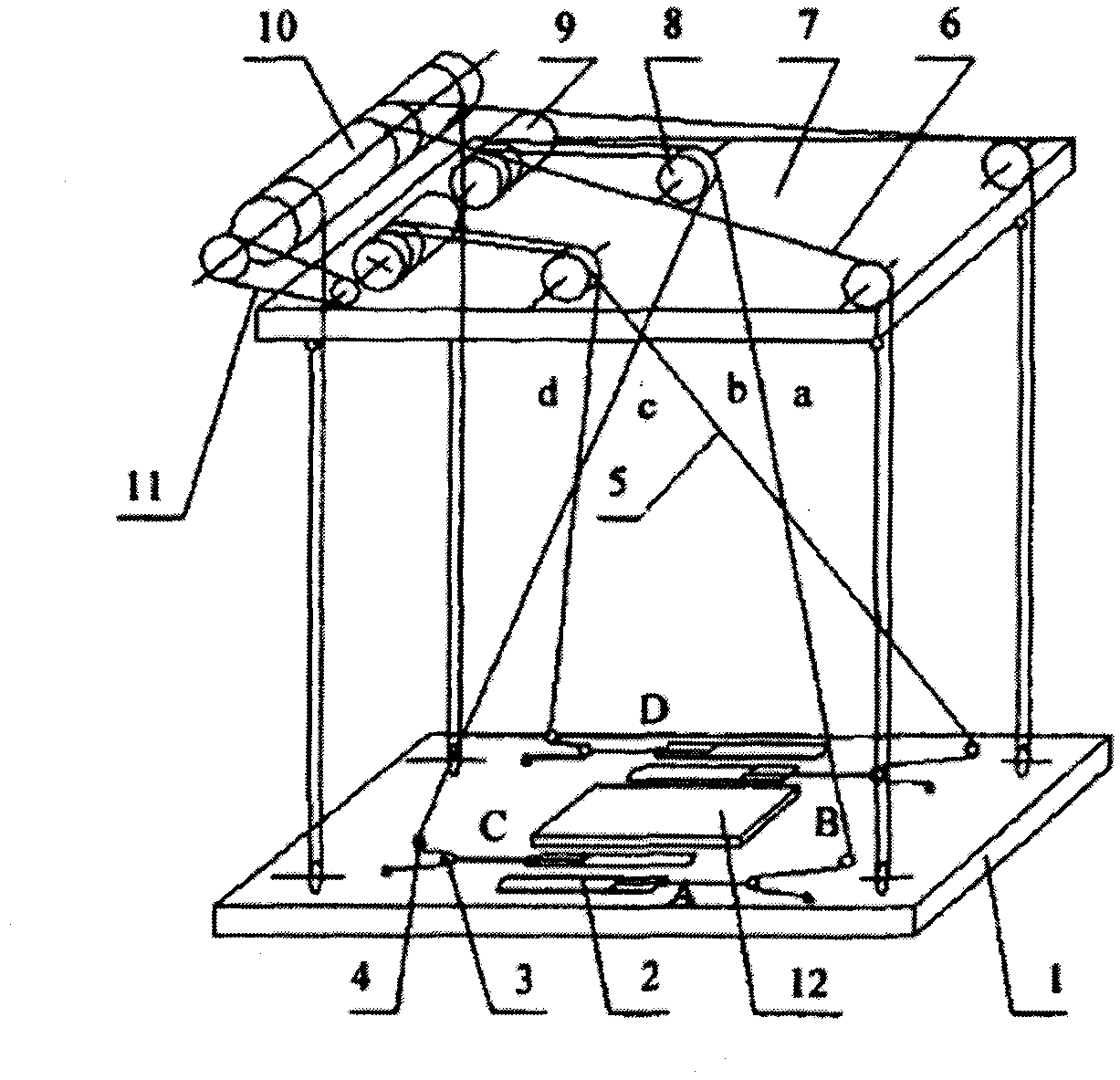

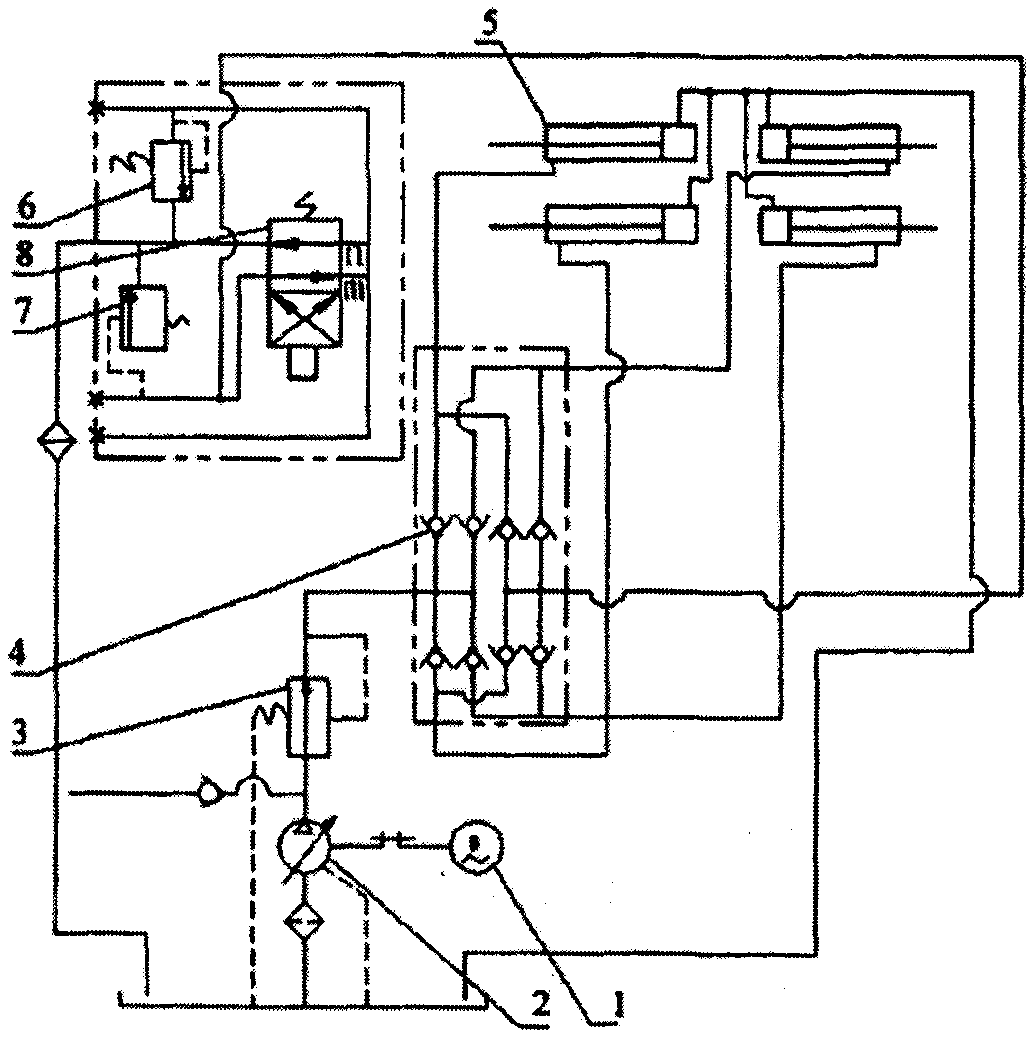

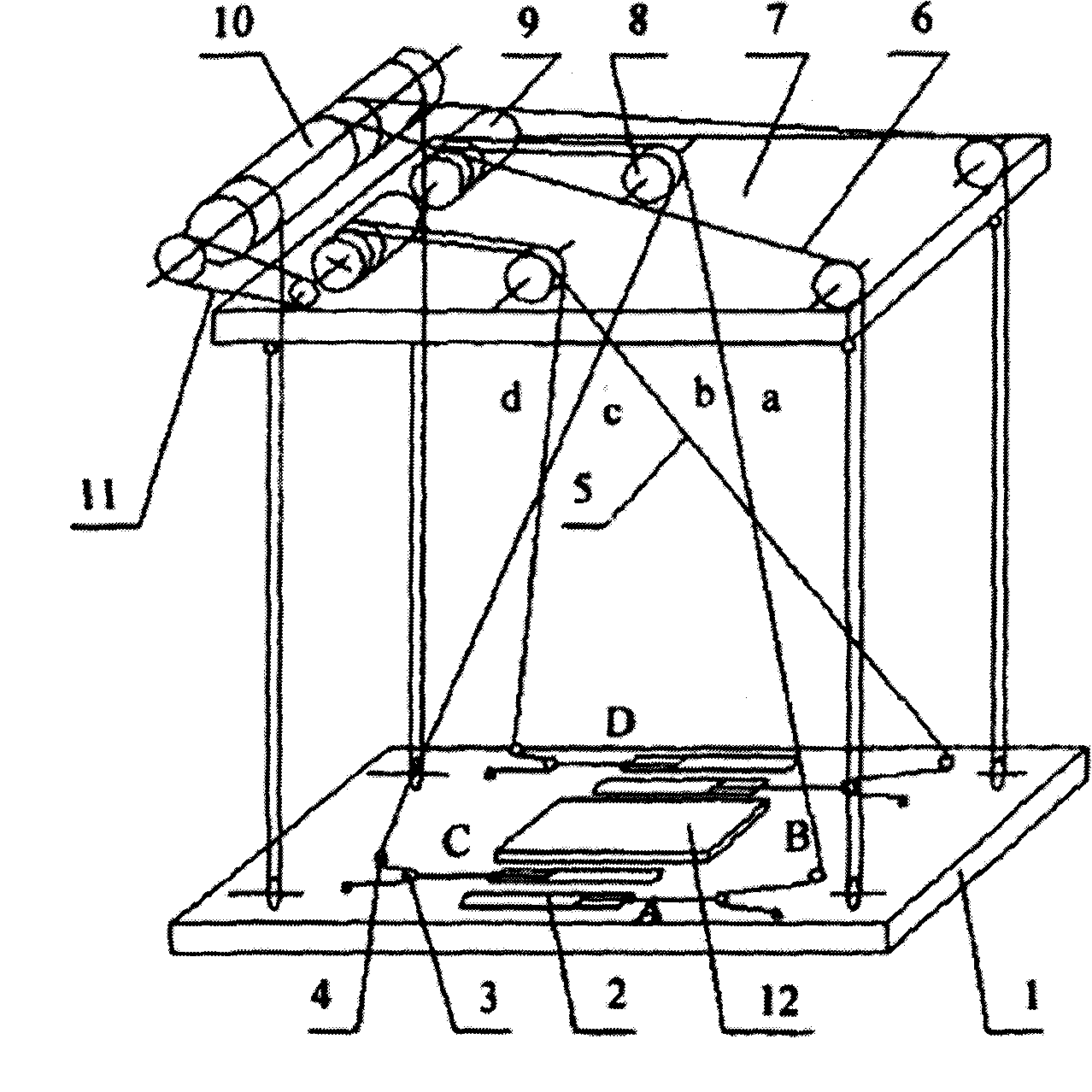

[0010] Such as figure 1 As shown, the system consists of an anti-sway reel 8 that rises and falls synchronously with the hoisting mechanism, an anti-sway wire rope 5, an anti-sway cylinder 2 (including A, B, C, D), a hydraulic pump station 11, and a pulley block 4. The anti-sway steel wire rope 5 (including ropes a, b, c, d) is cross-connected with the fixed pulley block 4 on the trolley frame 7 and the fixed pulley block 4 of the spreader 1, and the anti-sway drum 8 follows the lifting through the chain transmission device 10 The reels 9 rotate synchronously. When the cart or trolley frame 7 causes the spreader 1 to swing due to starting or braking, the swing of the hoisting weight is attenuated due to the cross-connection mode of the anti-sway rope and the effect of the hydraulic system. When the initial swing of the hoisting weight is to the right, the tension of rope a and rope b increases (in a tensioned state), and the tension of rope c and rope d decreases relatively (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com