Crude oil electro-desalting dehydrator

An electric desalination and dehydration, crude oil technology, applied in the direction of electric/magnetic dehydration/demulsification, electric/magnetic refining, etc., can solve the problems of high crude oil content in drainage, small electric field space, etc., to reduce crude oil content and space utilization. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

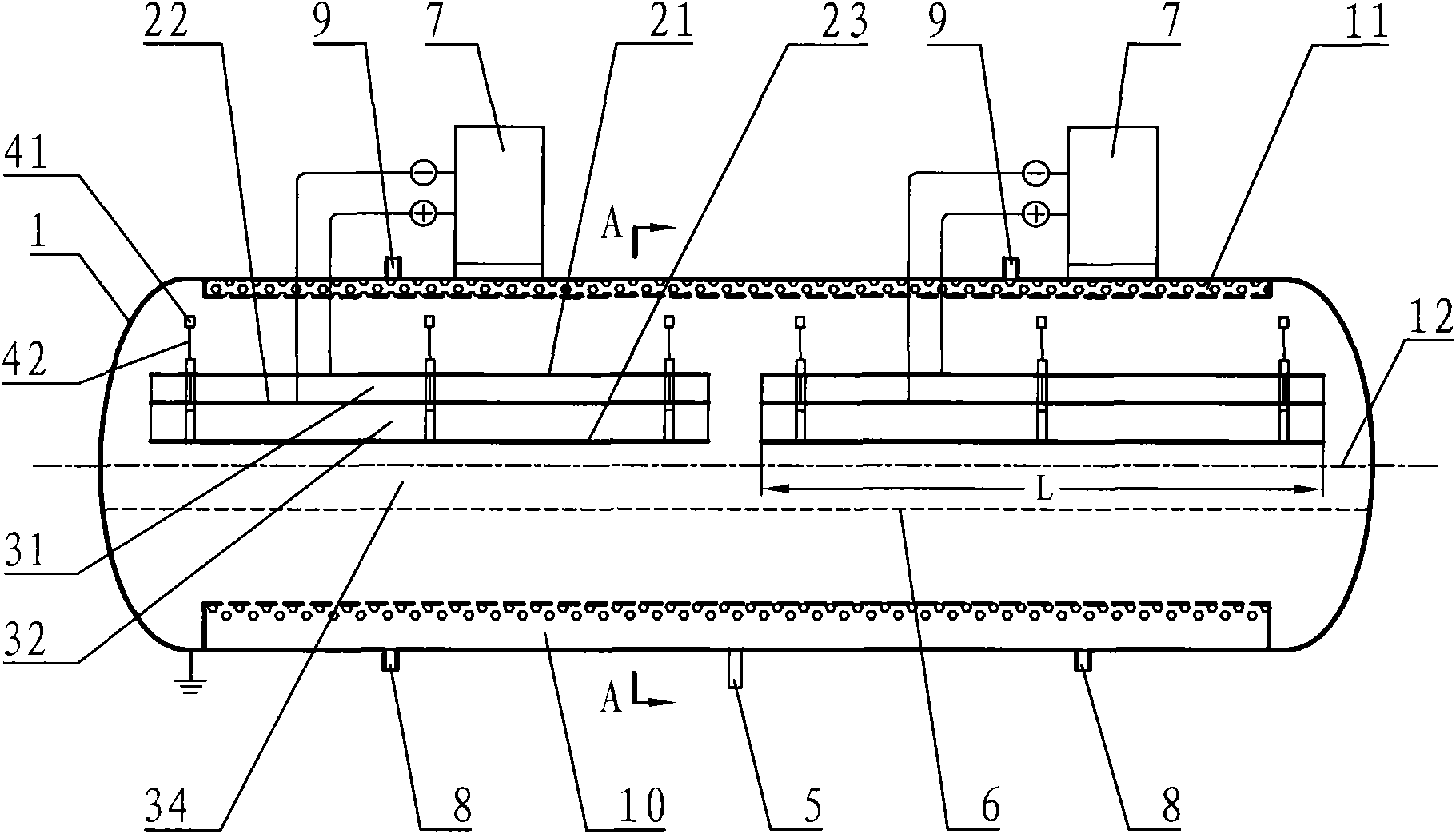

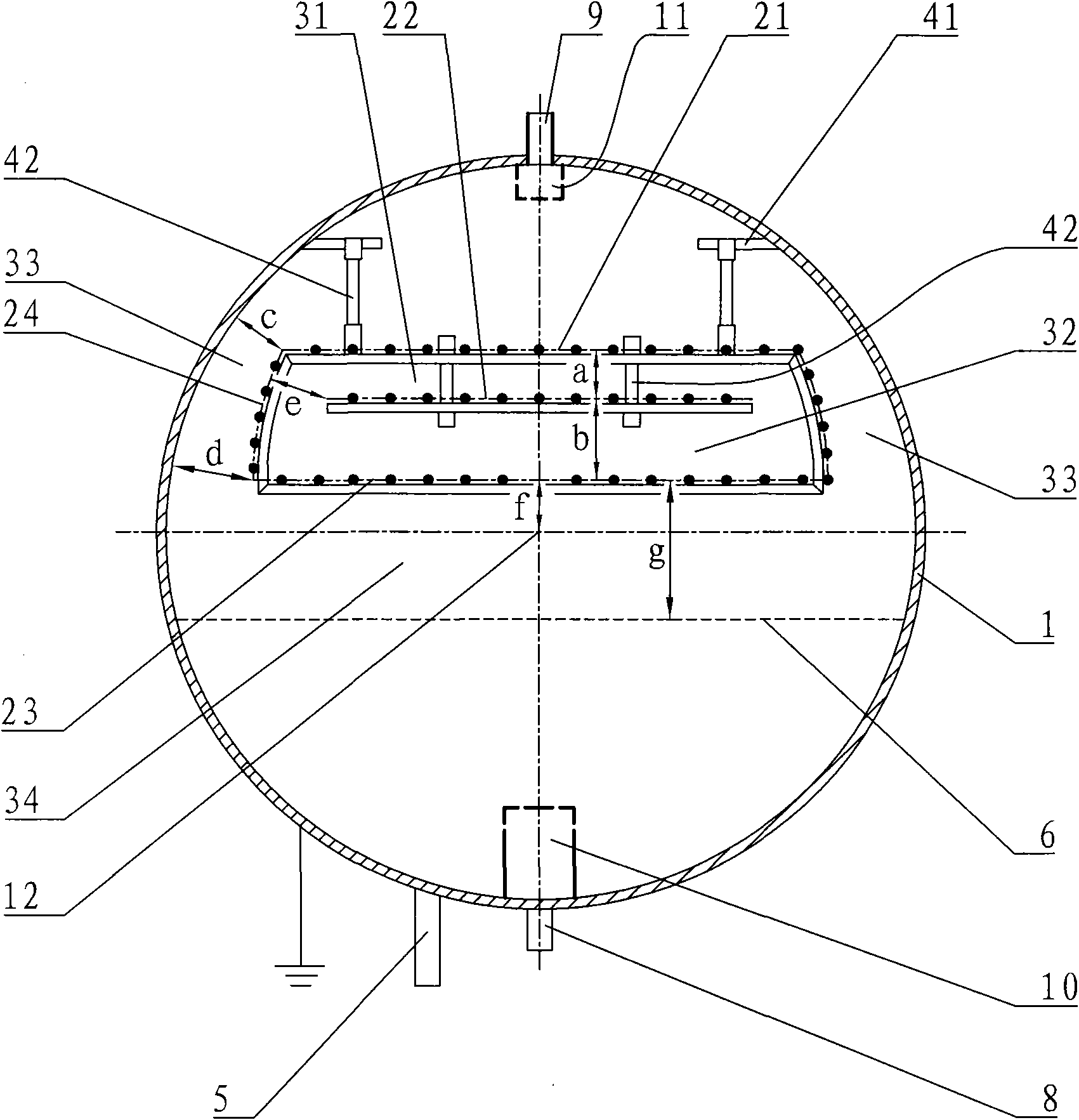

[0011] see figure 1 , figure 2 , The crude oil electric desalination dehydrator of the present invention includes a tank body 1 and a transformer 7 . The tank body 1 is a horizontal cylindrical tank body with electrodes inside. The bottom of the tank body 1 is provided with an inlet pipe 8 , a drain pipe 5 and a distributor 10 , and the top is provided with an outlet pipe 9 and a collector 11 . Among them, generally 2-4 inlet pipes 8 and outlet pipes 9 are arranged respectively, and 1-3 drain pipes 5 are generally arranged. figure 1 As shown, there are two inlet pipes 8 and two outlet pipes 9 respectively, and one drain pipe 5 is arranged.

[0012] The electrode level is provided with three layers of flat electrode plates (one more layer than the existing crude oil electric desalination dehydrator with two layers of flat electrode plates), and the three layers of flat electrode plates are the upper flat electrode plate 21 and the middle flat electrode from top to bottom. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com