Wrought magnesium alloy for high-speed extrusion and preparation method thereof

A technology for deforming magnesium alloys and magnesium alloys, applied in the field of metal processing, can solve the problems of low mechanical properties, inability to form enough pinned grains, increase production costs, etc., and achieve high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The weight percentage of each component of the alloy is: 3% Al, 0.1% Mn, 0.5% Si, 0.3% Ce, 0.5% Y, 0.1% Sr, 0.6% Sb, and the rest is Mg 9995 .

[0015] Prepare the alloy according to the above ingredients, heat the industrial magnesium alloy melting furnace to 400-500°C, add pure magnesium ingots (Mg 9995 ), pure aluminum ingots and pure silicon, after the pure magnesium ingots, aluminum ingots and pure silicon are all melted and stirred, add Al-Mn preheated to about 200°C 10 , Mg-Ce 25 , Mg-Y 60 , Al-Sr 10 Intermediate alloy, after the alloy is completely melted, raise the temperature of the alloy solution to 730-780°C, add pure antimony, add magnesium alloy refining agent for refining after stirring, keep the temperature for 20-60 minutes, then lower the temperature of the alloy solution to 690- Cast at 760°C into a solid round ingot for extrusion.

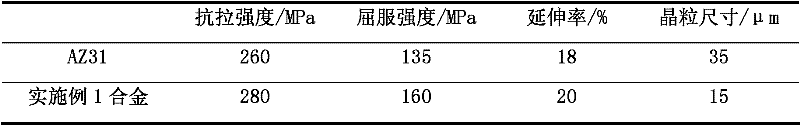

[0016] The alloy ingot is extruded at 420°C, and when the extrusion speed is 15m / min, the mechanical properties of...

Embodiment 2

[0019] The weight percentage of each component of the alloy is: 5% Al, 0.5% Mn, 2% Si, 1% Ce, 0.2% Y, 1Sr, 1% Sb, and the rest is Mg 9995 .

[0020] Prepare the alloy according to the above ingredients, heat the industrial magnesium alloy melting furnace to 400-500°C, add pure magnesium ingots (Mg 9995 ), pure aluminum ingots and pure silicon, after the pure magnesium ingots, aluminum ingots and pure silicon are all melted and stirred, add Al-Mn preheated to about 200°C 15 , Mg-Ce 35 , Mg-Y 25 , Al-Sr 30 Intermediate alloy, after the alloy is completely melted, raise the temperature of the alloy solution to 730-780°C, add pure antimony, add magnesium alloy refining agent for refining after stirring, keep the temperature for 20-60 minutes, then lower the temperature of the alloy solution to 690- Cast at 760°C into a solid round ingot for extrusion.

[0021] The alloy ingot is extruded at 420°C, and when the extrusion speed is 15m / min, the mechanical properties of the extru...

Embodiment 3

[0024] The weight percentage of each component of the alloy is: 8% Al, 1% Mn, 3% Si, 2% Ce, 1% Y, 0.5% Sr, 0.3% Sb, and the rest is Mg 9995 .

[0025] Prepare the alloy according to the above ingredients, heat the industrial magnesium alloy melting furnace to 400-500°C, add pure magnesium ingots (Mg 9995 ), pure aluminum ingots and pure silicon, after the pure magnesium ingots, aluminum ingots and pure silicon are all melted and stirred, add Al-Mn preheated to about 200°C 20 , Mg-Ce 50 , Mg-Y 90 , Al-Sr 20 Intermediate alloy, after the alloy is completely melted, raise the temperature of the alloy solution to 730-780°C, add pure antimony, add magnesium alloy refining agent for refining after stirring, keep the temperature for 20-60 minutes, then lower the temperature of the alloy solution to 690- Cast at 760°C into a solid round ingot for extrusion.

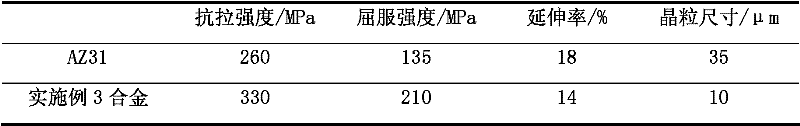

[0026] The alloy ingot is extruded at 420°C, and when the extrusion speed is 15m / min, the mechanical properties of the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com