Digital printing advertising cloth of fabric and manufacture process thereof

A digital printing and textile technology, applied in the direction of article advertising, textiles and papermaking, advertising, etc., can solve the problems of softness, poor sag, poor environmental performance and difficult folding of PVC advertising cloth, and achieve excellent weather resistance. The effect of aging, good adsorption and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

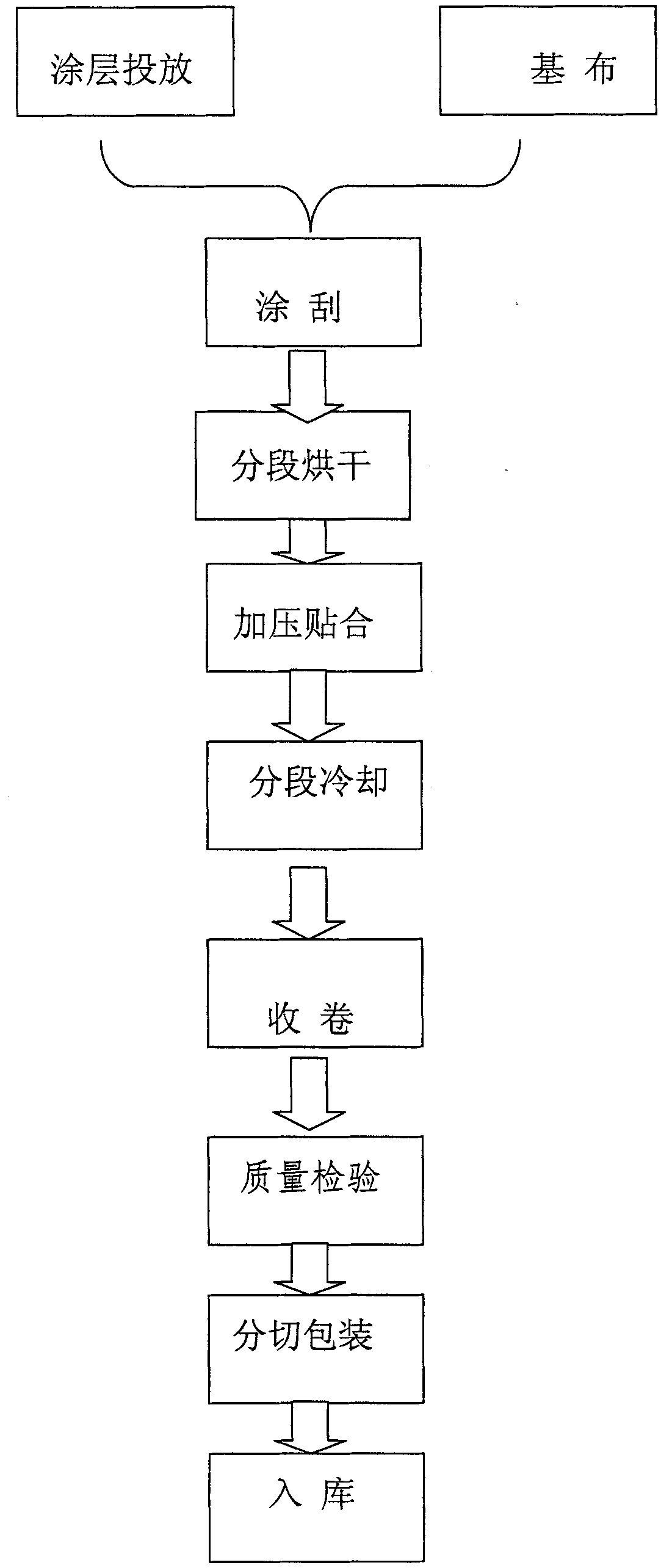

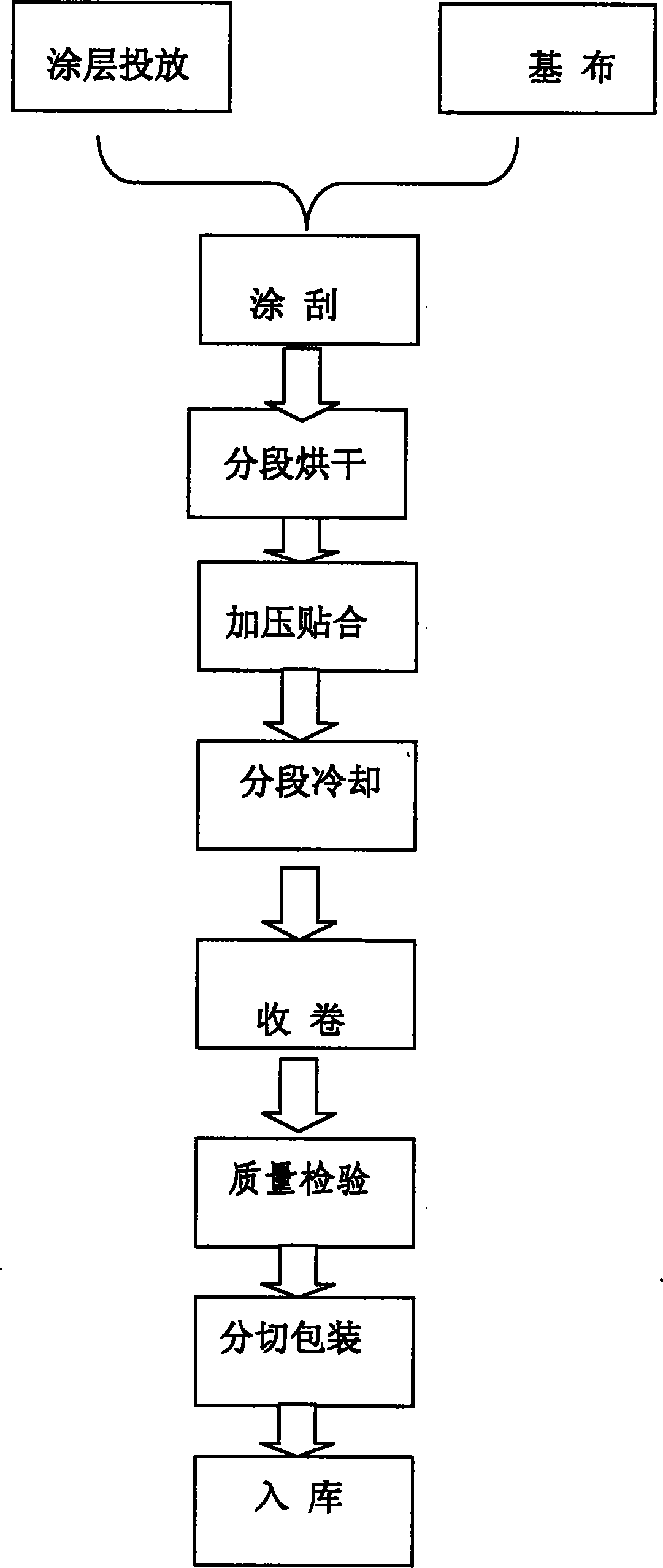

[0019] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

[0020] exist figure 1 Among them, the specific steps of the manufacturing process of the present invention are as follows:

[0021] a, the base cloth roll rotates at a constant speed with the roller shaft to the feeding table;

[0022] b, will add 35%-40% acrylic resin, 6%-8% silicon dioxide, 1%-2% whitening agent, 25%-30% titanium white paste, 6%-8% lubricating agent, 8%-10% plasticizer, 0.1%-0.2% dispersant, 15%-20% acetate solvent, the polymer mixture is evenly coated by roller 5-20m / min covered with base cloth;

[0023] c. The base fabric coated with the polymer mixture needs to be dried in five stages of temperature control; the first stage oven temperature is controlled at 80-90°C, the second stage oven temperature is controlled at 125-130°C, and the third stage oven temperature Control at 125-130°C, control the oven temperature in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com