Construction method for concrete beam with U-shaped steel bar connecting joints

A technology for concrete beams and connecting nodes, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of great influence on welding quality and technical level, high technical requirements for operators, and high monitoring and maintenance costs. The construction quality is easy to control, the wet work is reduced, and the effect of on-site construction is civilized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

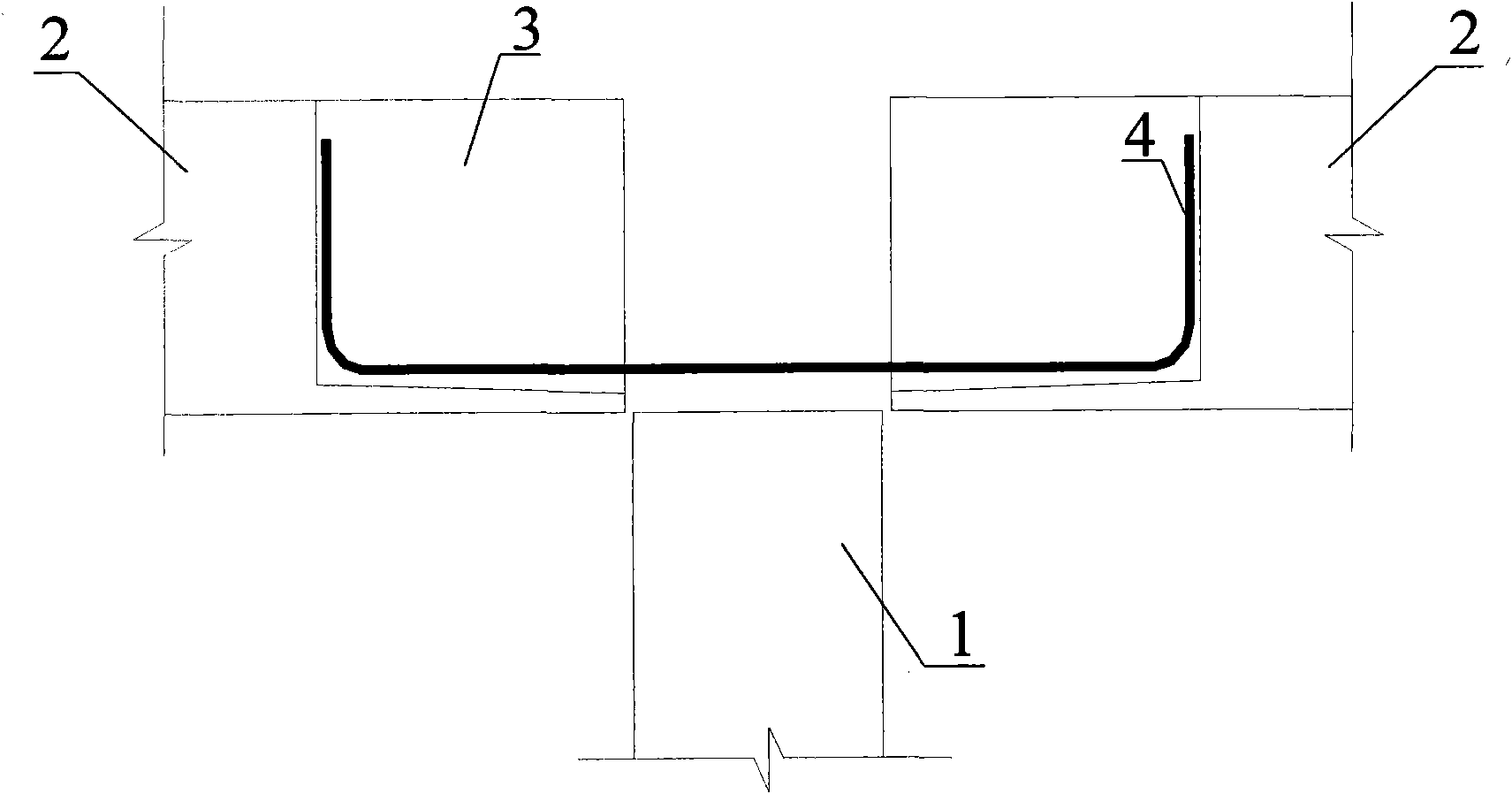

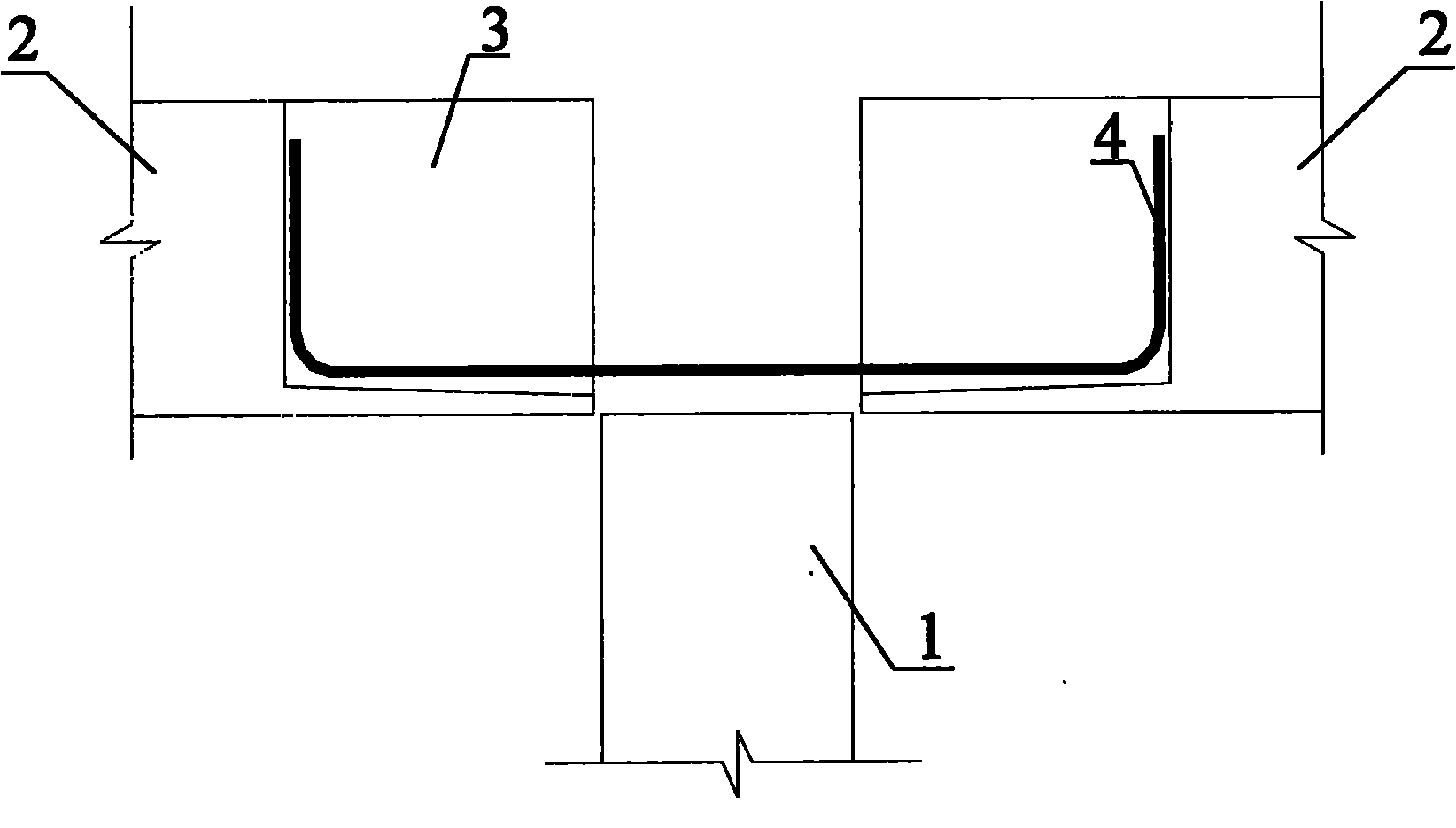

[0020] like figure 1 Shown:

[0021] Both ends of the prefabricated frame beam 2 are provided with grooves 3, and U-shaped steel bars 4 are placed in the grooves 3, and the prefabricated frame beam 2 and the column 1 are connected together by pouring concrete by using the U-shaped steel bars 4.

[0022] Description of construction method:

[0023] Lift the prefabricated frame beam 2 into place, put the U-shaped steel bar 4 into the groove 3 of the prefabricated frame beam 2, and pour concrete to connect the U-shaped steel bar 4 and the column 1 into one body.

[0024] Grooves 3 are respectively arranged at both ends of the prefabricated frame beam 2, and the steel bars (anchor bars) reserved at the ends of the beams are limited to the grooves 3 and are not exposed, so as to facilitate on-site installation;

[0025] Before hoisting the prefabricated frame beams, set up temporary supports first, and adjust the height of the supports according to the control elevation to ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com