Artistic lamp and processing method thereof

A processing method and lamp technology, applied in lighting and heating equipment, lighting devices, deodorization, etc., can solve the problems of slow cleaning speed, affecting the appearance of lamps, and high cost, so as to maintain cleanliness and appearance, improve lighting efficiency, reduce The effect of cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

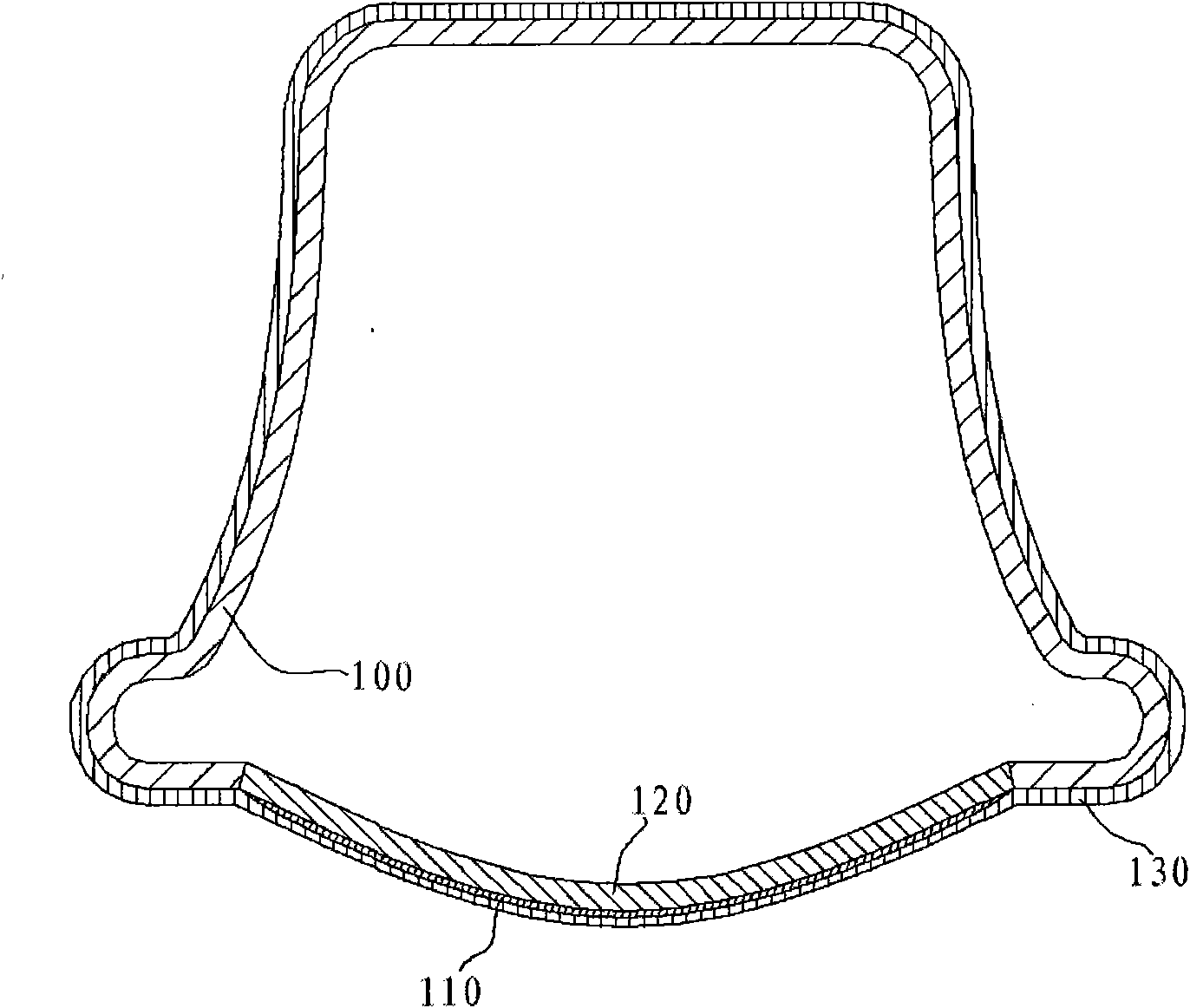

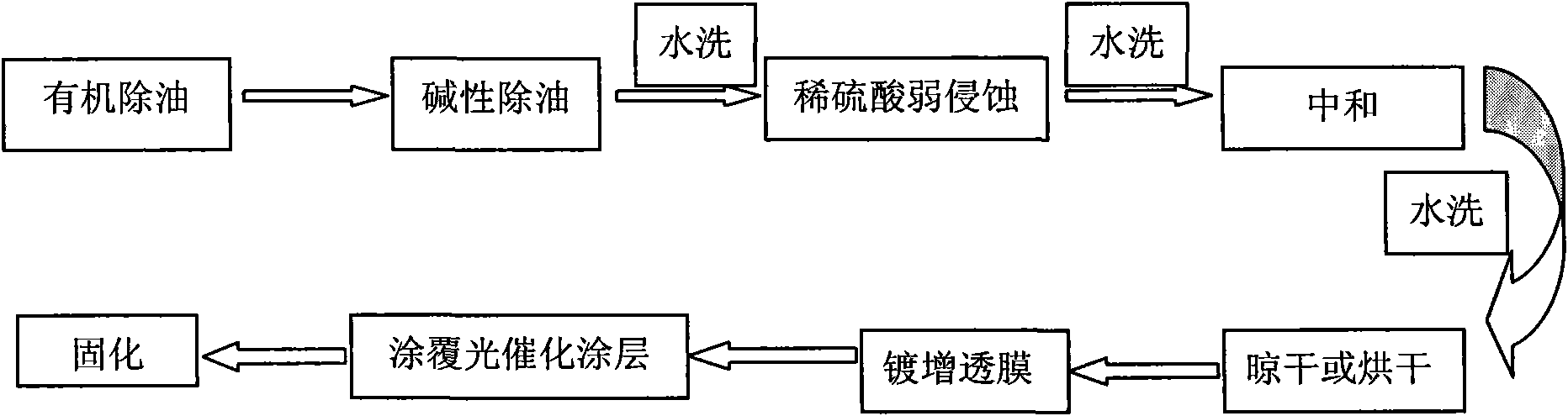

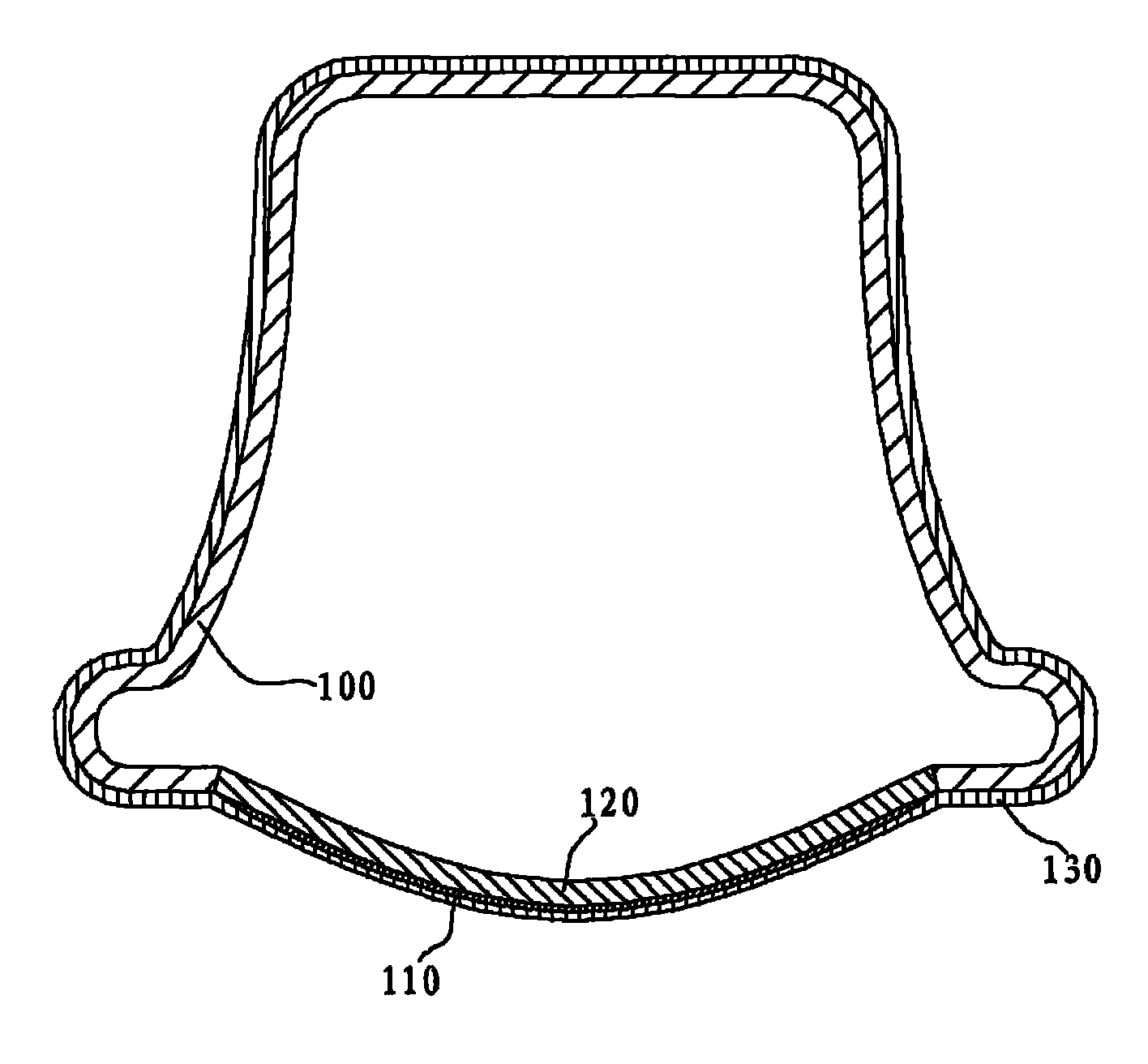

[0033] Firstly, the lamp housing 100 and the transparent member 120 are prepared. Then decontamination treatment is performed on the lamp housing 100 and the transparent member 120 . To be precise, the structural surface of the lamp (that is, the outer surface of the lamp housing 100 and the transparent member 120 ) is subjected to dust removal, oil removal and rust removal treatment to make the surface clean and free of impurities. The exemplary steps of the decontamination treatment are as follows: remove the transparent member 120 from the lamp housing 100, and put it together with the lamp housing 100 into the organic solvent acetone for organic degreasing; then put it into a sodium bicarbonate solution for alkaline degreasing oil; then put it into dilute sulfuric acid with a mass percentage concentration of 10% for weak erosion; finally put it into a sodium bicarbonate solution to neutralize the dilute acid. Preferably, after each step is completed, the lamp housing 100 ...

Embodiment 2

[0039] Firstly, the lamp housing 100 and the transparent member 120 are prepared. Then decontamination treatment is performed on the lamp housing 100 and the transparent member 120 . To be precise, the structural surface of the lamp (that is, the outer surface of the lamp housing 100 and the transparent member 120 ) is subjected to dust removal, oil removal and rust removal treatment to make the surface clean and free of impurities. The exemplary steps of the decontamination treatment are as follows: remove the transparent member 120 from the lamp housing 100, and put it together with the lamp housing 100 into the organic solvent acetone for organic degreasing; then put it into a sodium bicarbonate solution for alkaline degreasing oil; then put it into dilute sulfuric acid with a mass percentage concentration of 8% for weak erosion; finally put it into a sodium bicarbonate solution to neutralize the dilute acid. Preferably, after each step is completed, the lamp housing 100 a...

Embodiment 3

[0041] Firstly, the lamp housing 100 and the transparent member 120 are prepared. Then decontamination treatment is performed on the lamp housing 100 and the transparent member 120 . To be precise, the structural surface of the lamp (that is, the outer surface of the lamp housing 100 and the transparent member 120 ) is subjected to dust removal, oil removal and rust removal treatment to make the surface clean and free of impurities. The exemplary steps of the decontamination treatment are as follows: remove the transparent member 120 from the lamp housing 100, and put it together with the lamp housing 100 into the organic solvent acetone for organic degreasing; then put it into a sodium bicarbonate solution for alkaline degreasing oil; then put it into dilute sulfuric acid with a mass percentage concentration of 12% for weak erosion; finally put it into sodium bicarbonate solution to neutralize the dilute acid. Preferably, after each step is completed, the lamp housing 100 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com