Prefabricated assembled cable trench and installation method thereof

A prefabricated assembly and installation method technology, which is applied in the installation of cables, ground cables, electrical components, etc., can solve the problems of low plastering quality, difficulty in supporting formwork, and high resource consumption, etc. The effect of accumulating water at the bottom and facilitating the removal of accumulating water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

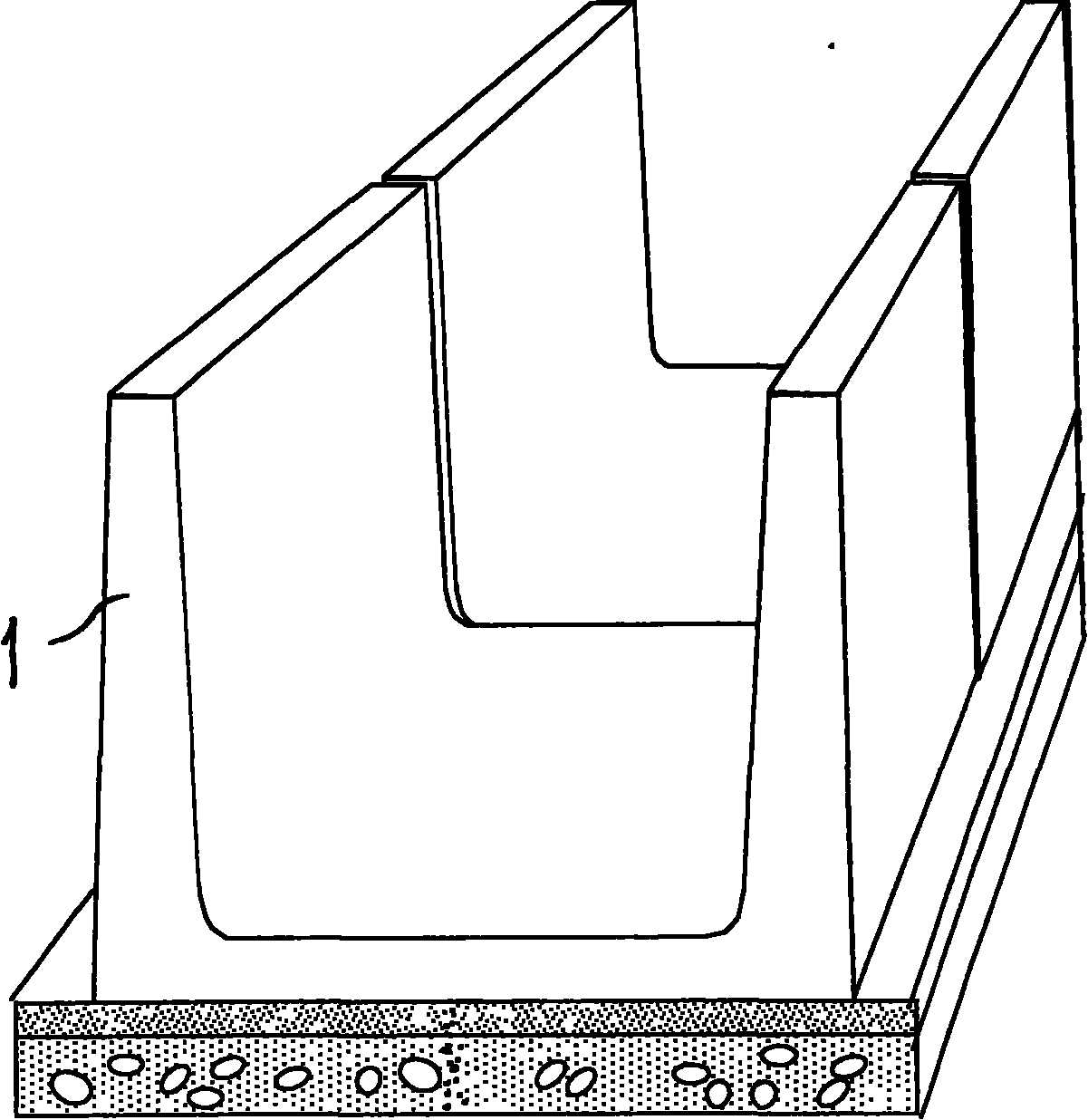

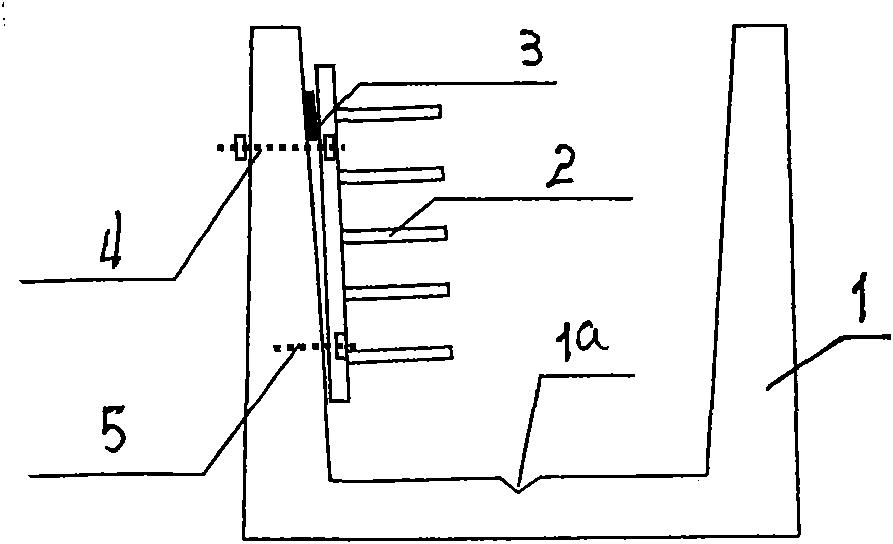

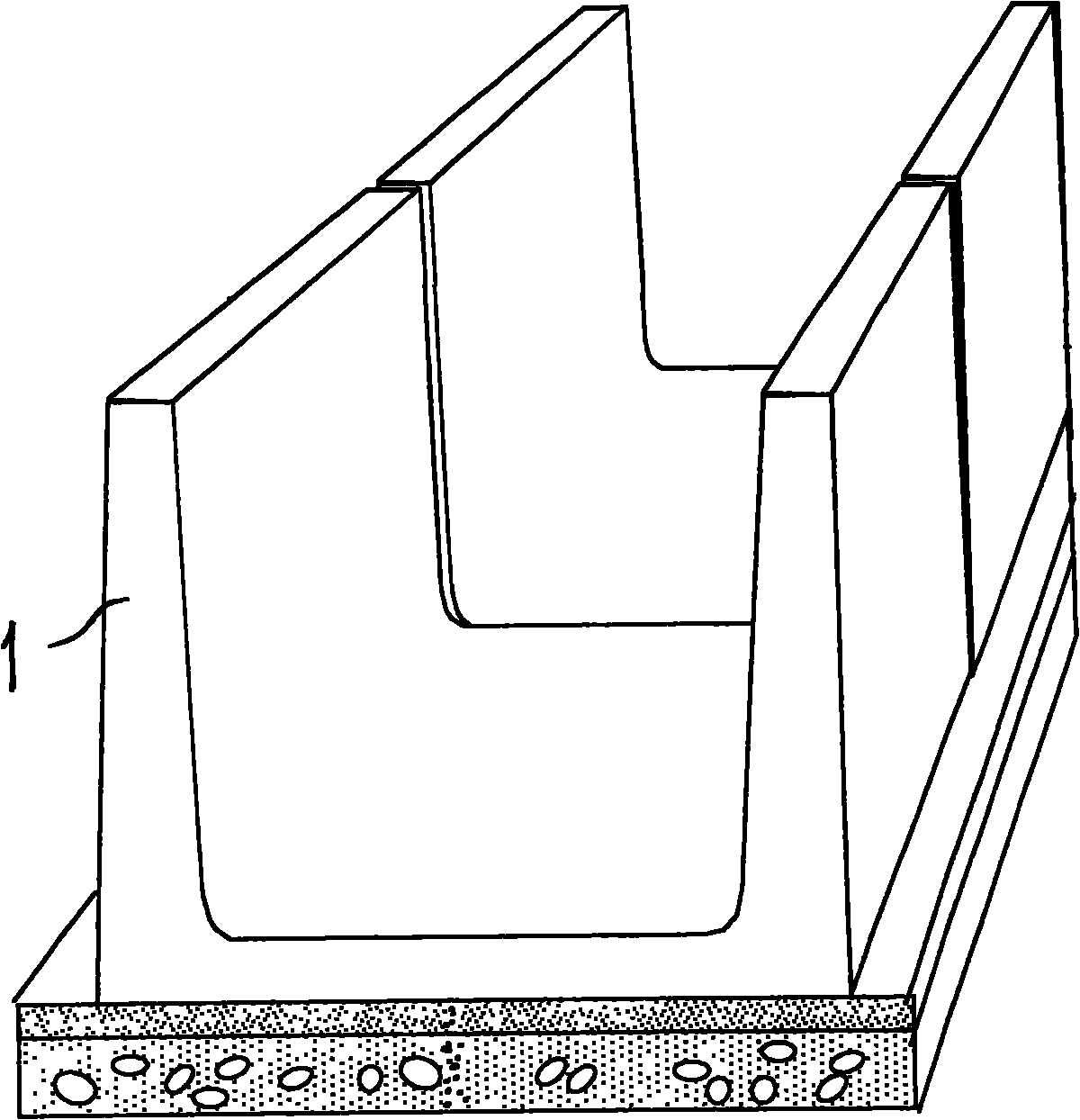

[0023] figure 1 It is shown that the present invention is composed of prefabricated cable trench monomers. The section of each cable trench monomer 1 is a "U"-shaped trench body, the mouth of the trench body is wide at the top and narrow at the bottom, and the left and right trench wall sections of the trench body are narrow at the bottom and wide at the bottom. The left and right ditch walls are symmetrical and gradually shrink and narrow from bottom to top, and there is an arc-shaped drainage groove 1a at the bottom of the ditch body. The length of the single cable trench is 1m. Reinforcement rings are pre-embedded on the single cable trench.

[0024] see figure 2 , a method for installing a prefabricated cable trench, the steps are as follows:

[0025] a) The ditch body is installed on the 100mm thick plain concrete soil cushion. During installation, 30-50mm dry hard cement mortar is laid for leveling. The ditch body is lifted and installed by an 8-ton crane; Reserve a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com