Laser cutting machine structure

A laser cutting machine and laser head technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low cutting precision, difficulty, and large difference in optical parameters, etc., to ensure effective distance accuracy, focus The effect of fine points and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

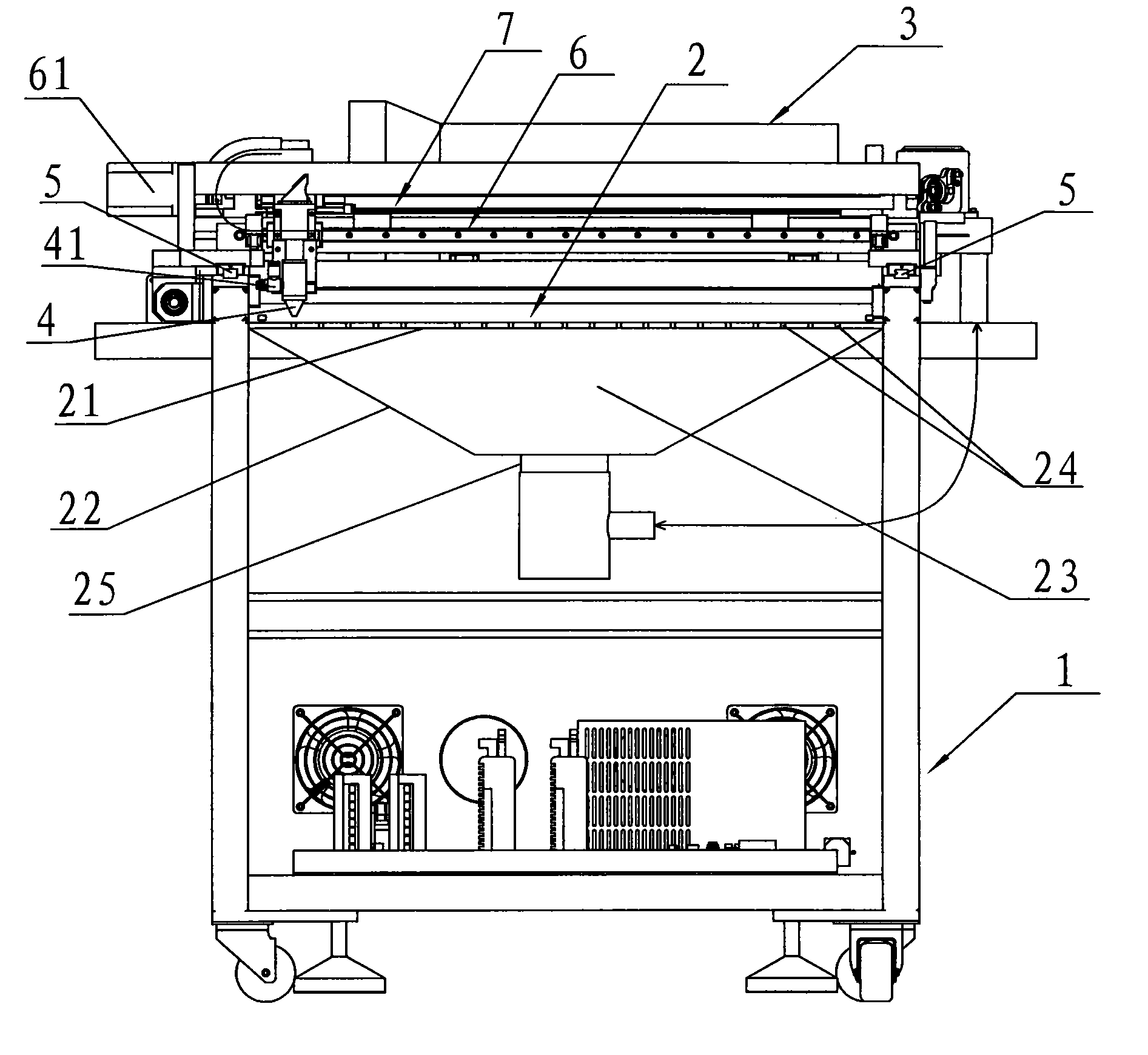

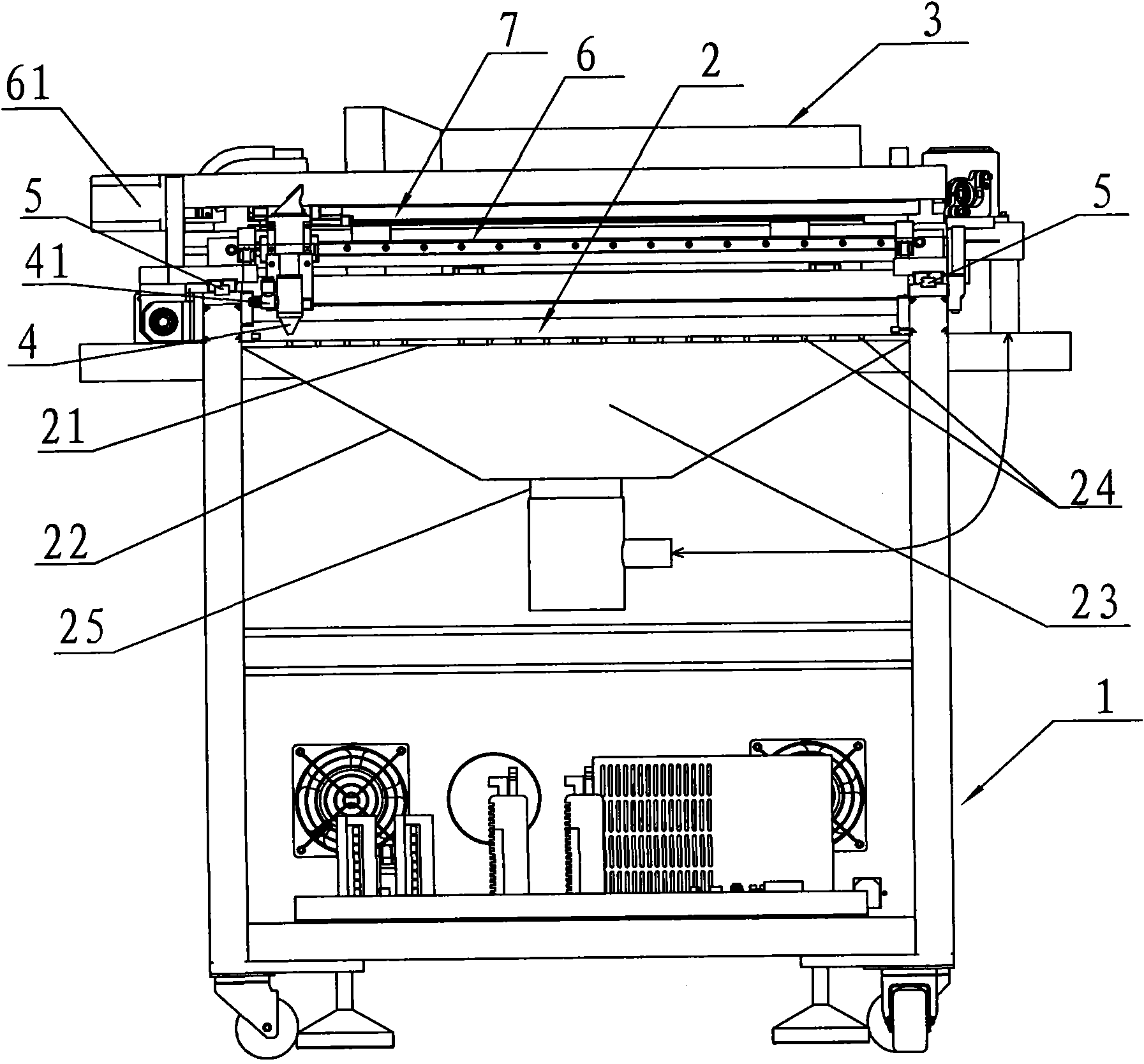

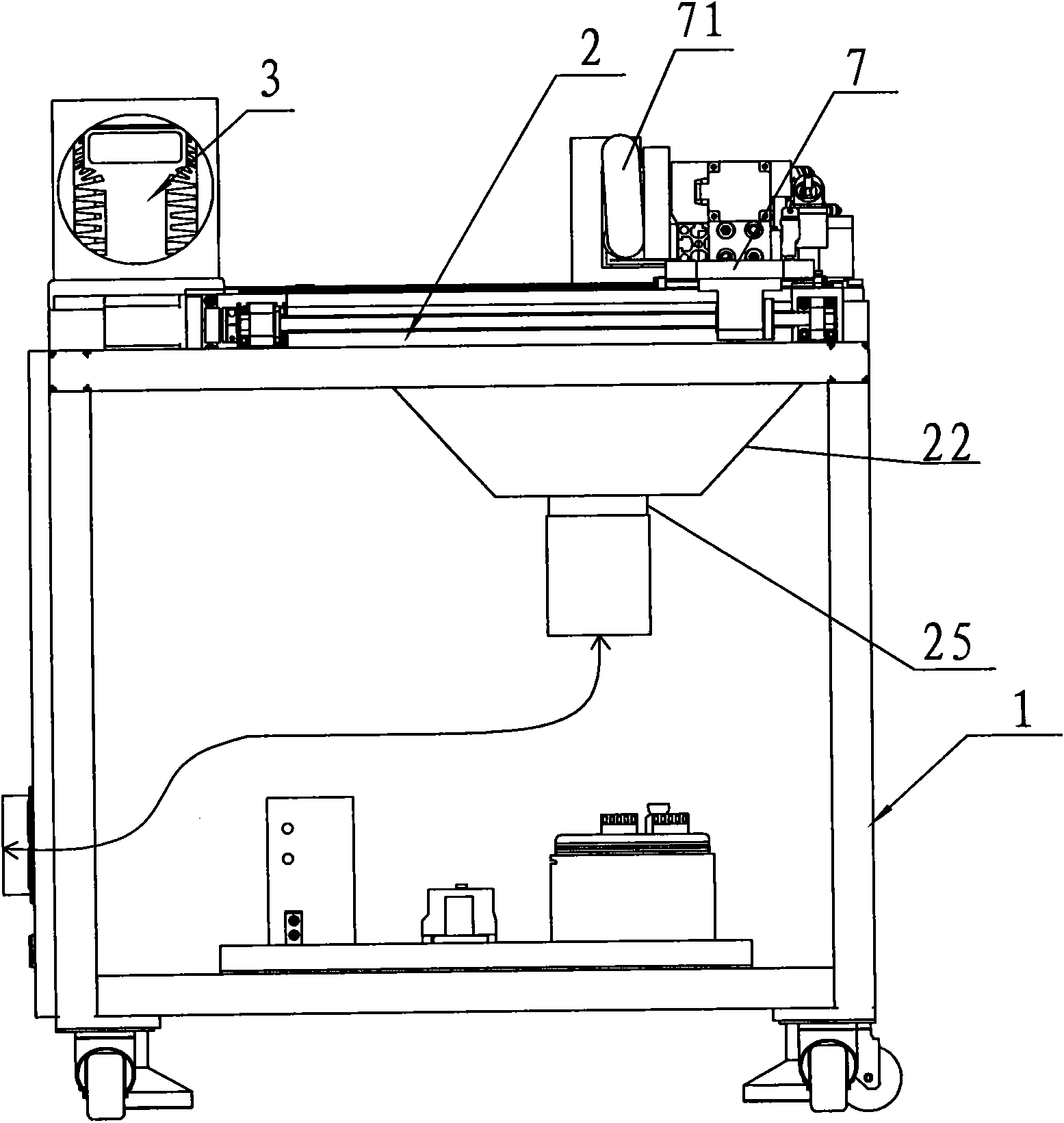

[0030] As shown in Figures 1-12, a laser cutting machine structure, the device also includes a frame 1, a working platform 2, a laser generator 3, a laser head 4, a Y-axis guide rail 5, an X-axis guide rail 6, and a moving beam 7 , Y-axis driving motor 51 and X-axis driving motor 61, the working platform 2 comprises an adsorption worktable 21 and an adsorption bucket 22, the adsorption bucket 22 is buckled on the bottom of the adsorption worktable 21 to form an adsorption chamber 23, and the adsorption The bucket 22 is a tapered bucket, and the adsorption workbench 21 is provided with through holes 24 uniformly arranged in an array along the surface of the board to communicate with the adsorption chamber 23 and lead to the workbench surface. Connect the exhaust fan.

[0031] The Y-axis guide rail 5 is arranged on the left and right sides of the working platform 2, and the moving beam 7 is erected on the Y-axis guide rail 5 and driven by the Y-axis driving motor 51; the X-axis ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap