Design method of engineering bridge transport vehicle

A design method and technology of transport vehicles, which are applied in the direction of vehicles used to carry long goods, and can solve the problem of large longitudinal distance between the position of the steering gear and the steering arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

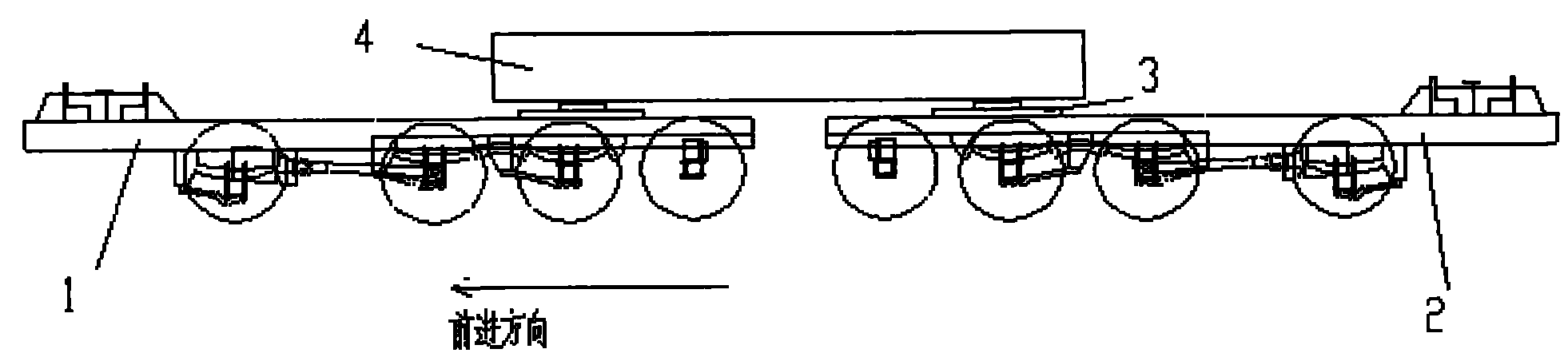

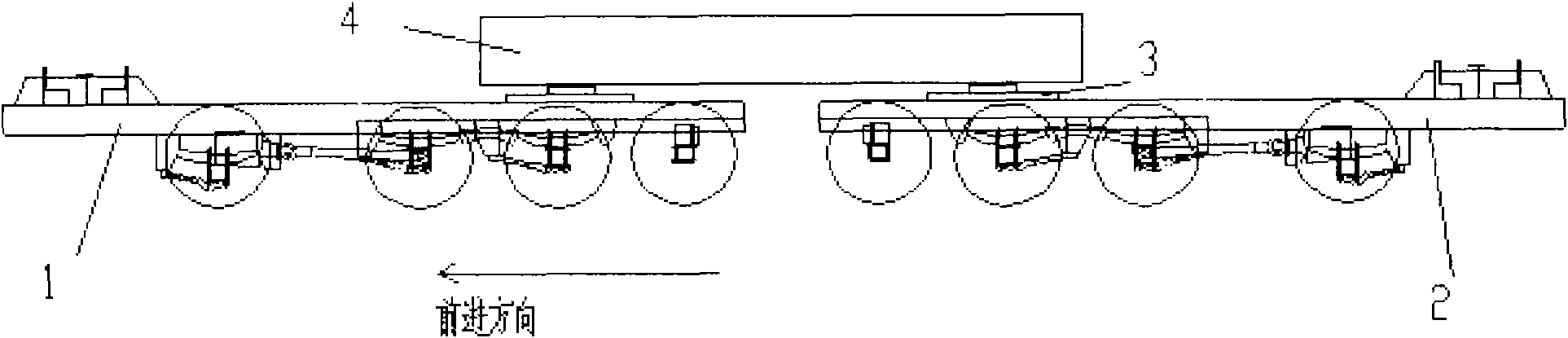

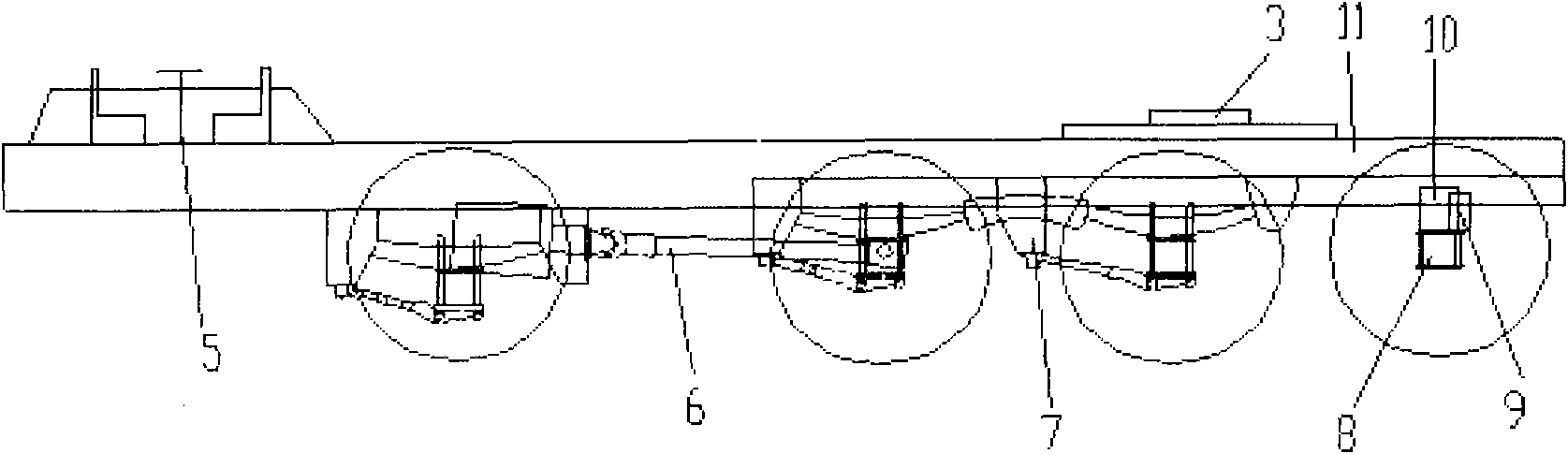

[0046] Embodiment 1: as shown in Fig. 1 and Fig. 2 and Fig. 3, this engineering bridge transport vehicle, it comprises front car 1, rear car 2, working device, the working turntable 3 of working device, bridge 4, steering system 5, Transmission system 6, suspension system 7, anti-overturn bridge 8, braking system 9, anti-overturn bridge connection seat 10, vehicle frame 11, operating platform 12 and connectors thereof, its front car 1 and rear car 2 pass through respectively The working device is connected to the front and rear of the same bridge 4; the operating platform 12 has a two-way operating system, and the driver can drive in both forward and reverse directions according to different needs, so that the car can be driven out quickly after the bridge is removed. Subgrade, its front car 1 and rear car 2 have the same structure, and the front car 1 and rear car 2 are lifted up symmetrically by the working turntable 3 of their respective working devices and installed on the ...

Embodiment 2

[0049] Embodiment 2: As shown in Figure 2-1, it is basically the same as Embodiment 1, the difference is its engineering vehicle mechanical hydraulic power steering device, which at least includes a steering gear support 2-1, a steering gear 2-2 , lock nut 2-3, steering drop arm 2-4, front steering straight rod 2-5, booster cylinder support 2-6, steering rocker support 2-7, steering rocker arm 2-8, rear steering straight Pull rod 2-9, power steering cylinder 2-10, steering shaft 2-11, steering arm 2-12, steering tie rod 2-13.

[0050]The left steering gear 2-2 is fixed on the steering gear support 2-1 through bolts, the steering pendant arm 2-4 is connected to the steering gear 2-2 through the lock nut 2-3, and the steering rocker arm 2-8 is fixed on the steering gear support 2-1 through the bolts. Connected to the steering rocker arm support 2-7, one end of the front steering straight tie rod 2-5 is connected to the steering drop arm 2-4, the other end is connected to the ste...

Embodiment 3

[0053] Embodiment 3: As shown in Figure 3-1, on the basis of Embodiment 1 or Embodiment 1 and Embodiment 2, it requires two-way manipulation of the clutch, and the clutch manipulation in the transmission system 6 adopts two-way clutches with the same structure and symmetrical connection. An operating mechanism, which at least includes a reverse clutch pedal 3-3, a forward clutch pedal 3-4, a reverse manipulation liquid storage tank and a pipeline 3-1, a forward manipulation fluid storage tank and a pipeline 3-2, a reverse Control clutch master cylinder 3-5, forward control clutch master cylinder 3-6, reverse control manual control valve 3-7, forward control manual control valve 3-8 and tee joint 3-9, forward control liquid storage The tank and pipeline 3-2 are connected to the forward steering clutch master cylinder 3-6 with rubber hoses and joints, and the forward clutch pedal 3-4 is connected to the forward steering clutch master cylinder 3-6 with bolts. The forward steering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com