Method for producing paraxylene

A p-xylene and toluene technology, applied in the field of p-xylene production, can solve the problems of high energy consumption, large circulation volume of xylene separation unit and isomerization unit, etc.

Active Publication Date: 2010-08-25

CHINA PETROLEUM & CHEM CORP +1

View PDF2 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is that in the production of p-xylene in the prior art, there are problems such as the low concentration of p-xylene in the mixed xylene, resulting in large circulation of xylene separation unit and isomerization unit, high energy consumption, etc., providing A new production method of p-xylene

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

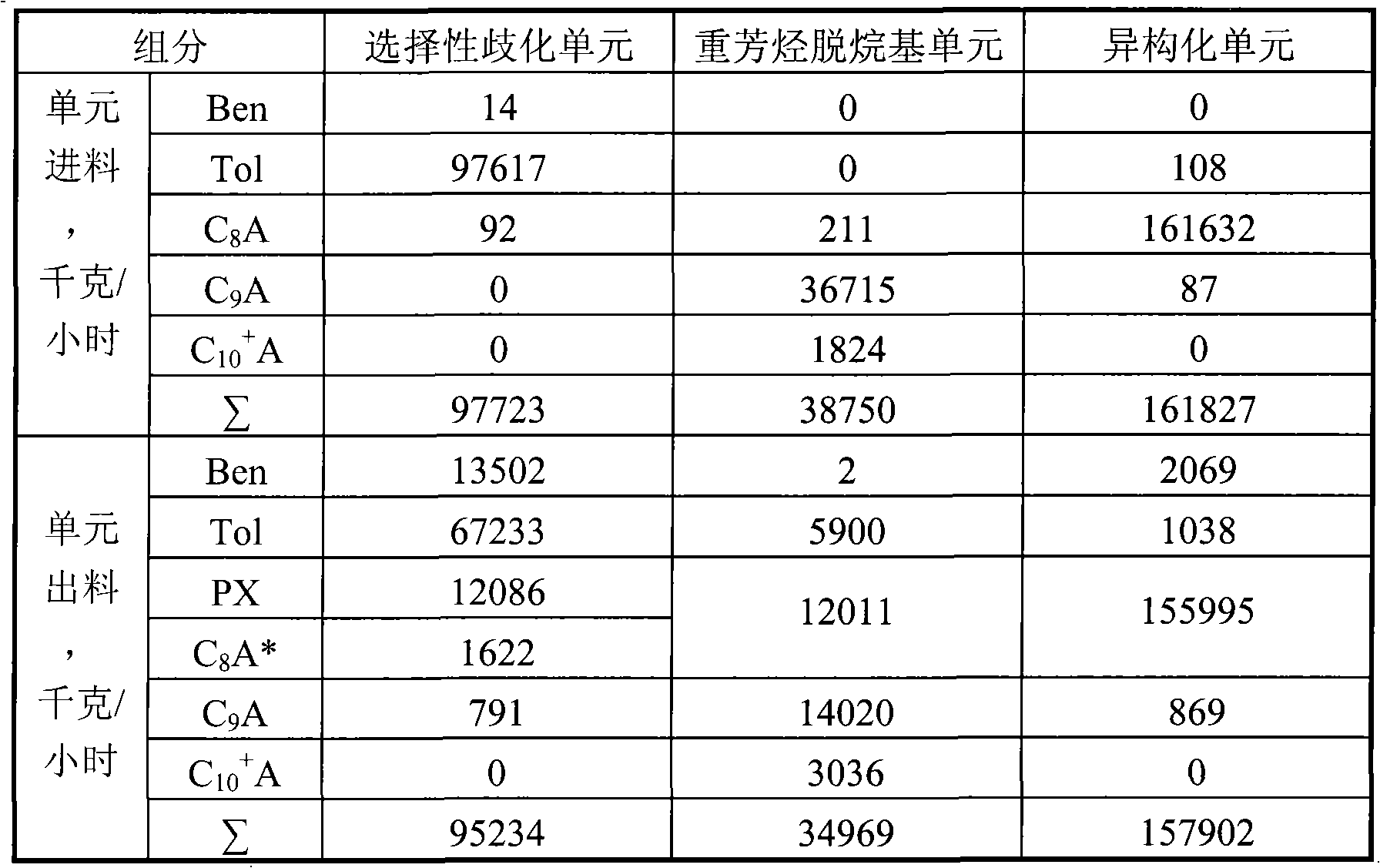

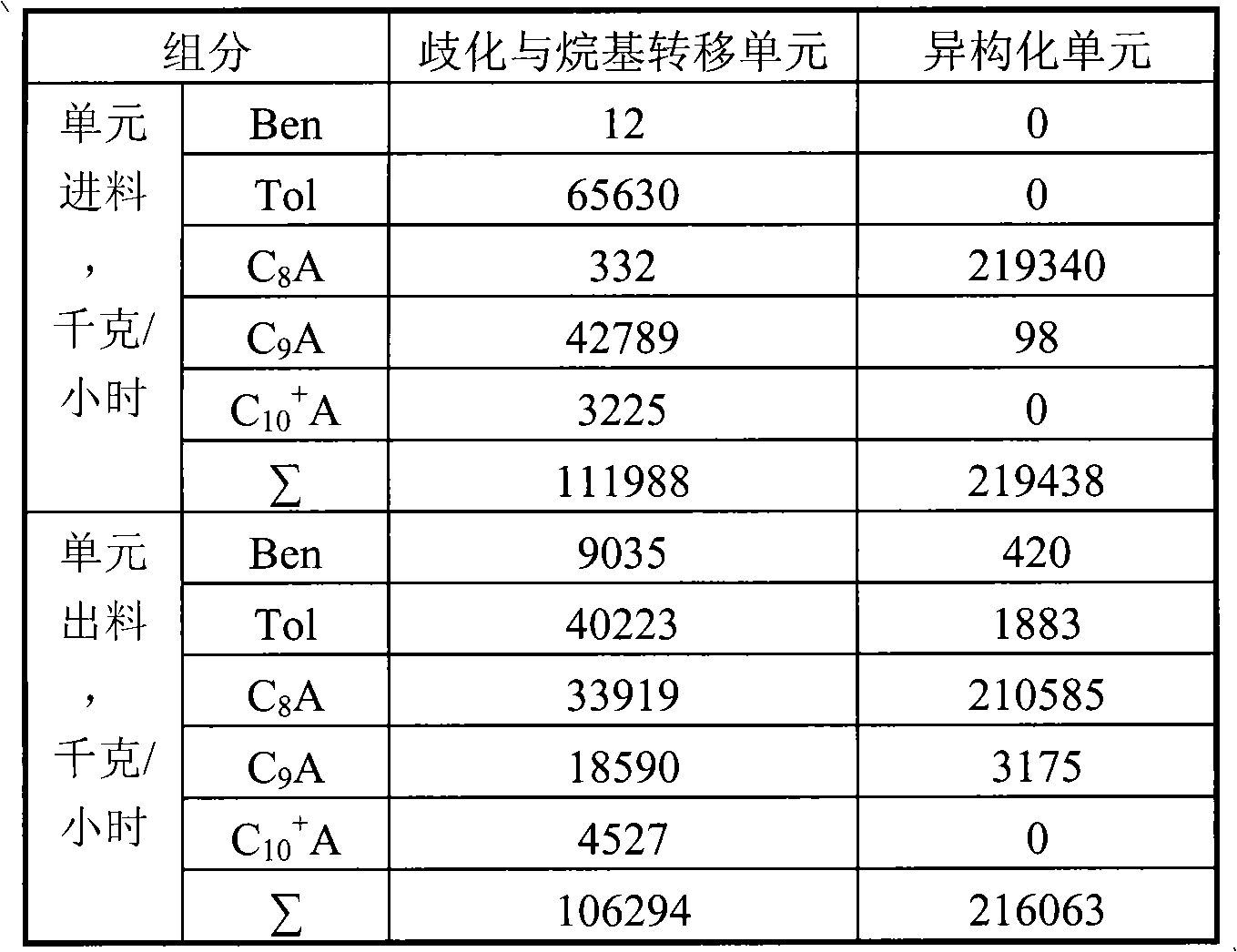

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

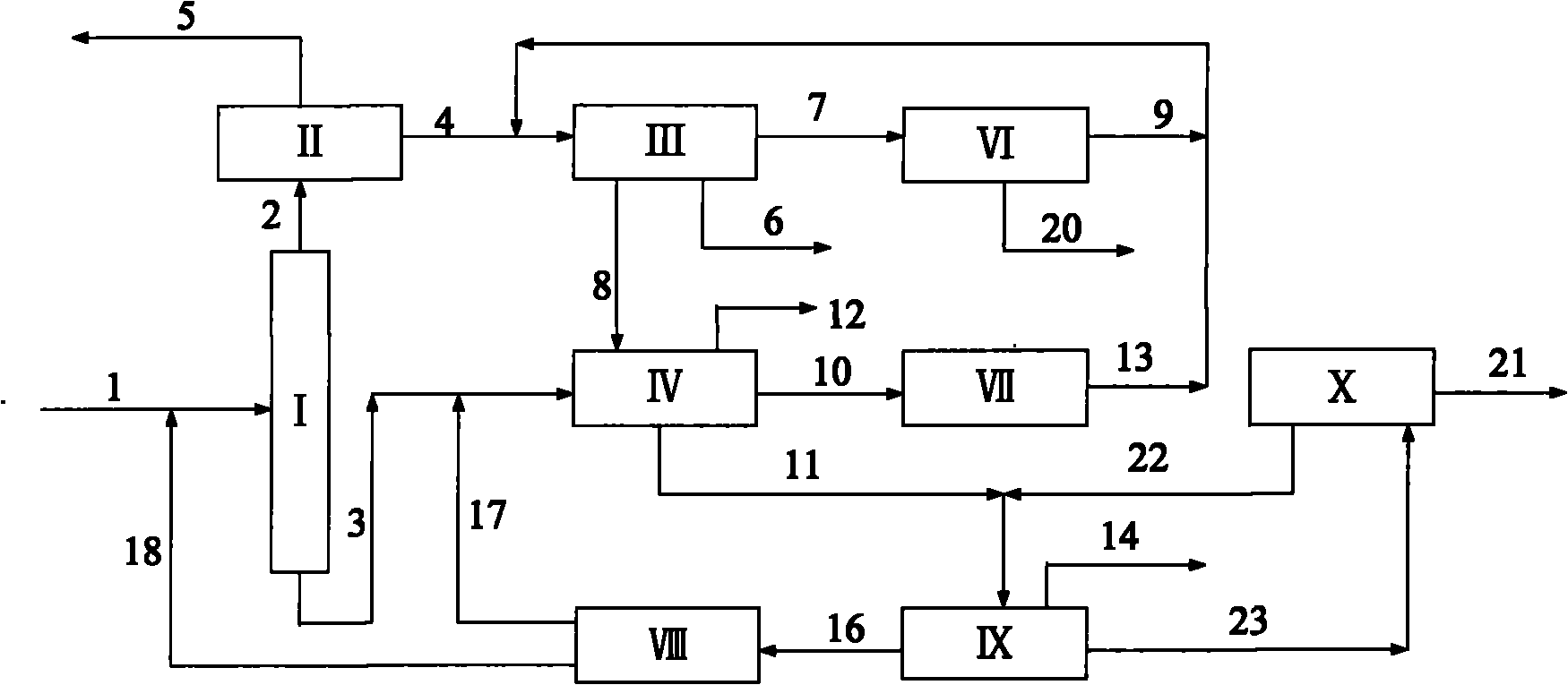

The invention relates to a method for producing paraxylene, which manly solves the problems of low concentration of paraxylene in mixed xylene during paraxylene production, large circulating load of aromatic hydrocarbon treatment, strict requirements for raw reaction materials, high energy consumption and the like existing in the prior art. The method comprises the following steps of: separating mixed raw materials from a reforming unit; introducing separated C9 and heavier aromatic hydrocarbons into a C9 and heavier aromatic hydrocarbon dealkylation processing unit for a dealkylation reaction to produce a second part of benzene, a second part of methylbenzene and a second part of C8 aromatic hydrocarbon; introducing methylbenzene into a methylbenzene selective disproportionation processing unit for a selective disproportionation reaction of methylbenzene to produce a C8 aromatic hydrocarbon and benzene flow including paraxylene so as to obtain a third part of C8 aromatic hydrocarbon,a third part of methylbenzene and a third part of benzene; after mixing the low-concentration C8 aromatic hydrocarbon, introducing the mixture into a crystallization and separation unit to obtain C8 aromatic hydrocarbon including paraxylene with high concentration; and introducing the C8 aromatic hydrocarbon including paraxylene with high concentration into an absorption and separation unit to obtain the product of paraxylene. With the technical scheme, the invention well solves the problems and can be applied to the industrial production of paraxylene.

Description

technical field The invention relates to a method for producing p-xylene. Background technique P-xylene is one of the main basic organic raw materials in the petrochemical industry. It is widely used in many chemical production fields such as chemical fibers, synthetic resins, pesticides, medicines, and plastics. The typical production method of p-xylene is from the thermodynamically balanced xylene containing ethylbenzene, that is, C8 aromatics generated by catalytic reforming of naphtha, through multi-stage cryogenic crystallization separation or molecular sieve simulated moving bed adsorption separation (adsorption separation for short) Technology to separate p-xylene from a mixture of isomers with similar boiling points. For the treatment of ortho- and meta-xylene, C 8 A isomerization (referred to as isomerization) technology to isomerize it into p-xylene. In order to increase the production of p-xylene, the disproportionation of toluene or the disproportionation and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07C15/08C07C4/12C07C5/52C07C7/12C07C7/14C07C7/00

Inventor 钟禄平肖剑杨卫胜郭艳姿张惠明

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com