Wet method lixiviating method for copper-contained tailings

A technology of copper tailings and leaching, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of uneconomical copper extraction process, and achieve the effects of alleviating the shortage of copper resources, low production costs and good economic benefits

Active Publication Date: 2010-08-25

ZIJIN MINING GROUP

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This part of the tailings is strongly alkaline. If the traditional acid method is used for recovery, a large amount of acid will be consumed, making the copper extraction process uneconomical.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a wet method lixiviating method for copper-contained tailings, belonging to a tailing comprehensive utilization technical method. The method comprises the following steps of: firstly carrying out soda treatment on the copper-contained tailings, then adding ammonium salt with a certain concentration, respectively carrying out dump leaching and agitation leaching according to the thickness of the granularity of the copper-contained tailings to obtain lixivium having higher copper concentration, finally recovering metal copper with conventional extraction, electrowinning process or direct electrowinning, and returning an ammonium salt contained solution for lixiviating. The method has the advantages of simple process, short process, low energy consumption, no additional equipment, easy implementation, comprehensive recovery of copper resource, less investment and low production cost, and is a copper recovering method which is easy to realize industrial production and has good economic benefits.

Description

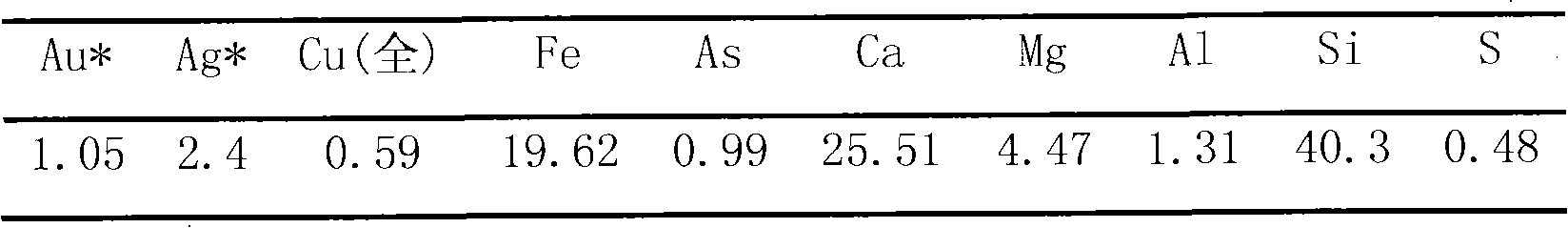

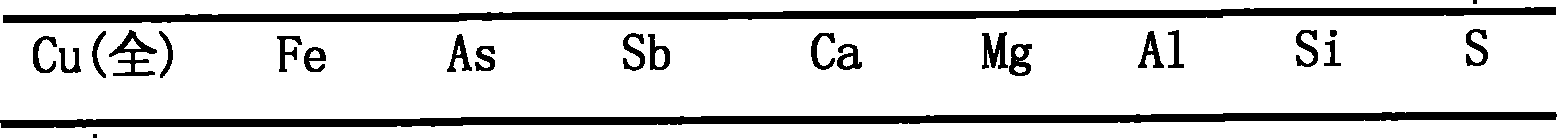

technical field The invention relates to a tailings comprehensive utilization method, in particular to a wet leaching method for copper-containing tailings. Background technique Copper is an important non-ferrous metal and an irreplaceable important raw material in the development of the national economy. It is widely used in various fields of military industry, electronics, communications, construction, light industry, machinery manufacturing and transportation. With the development of the national economy, The demand for copper is increasing year by year. my country needs to import a large amount of copper raw materials and products every year, and the contradiction between supply and demand of copper is very prominent. A large amount of copper-containing tailings exists in the selective leaching gold extraction tailings of gold mines and intermediate products of copper smelting processes, such as waste water and slag. This part of the tailings is strongly alkaline. If t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B3/12C22B3/18C25C1/12

CPCY02P10/20

Inventor 阮仁满衷水平甘永刚

Owner ZIJIN MINING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com