Hydraulic vibration rock splitter

A technology of hydraulic vibration and splitter, which is applied in the fields of discharging machinery, earthwork drilling and mining, etc., can solve the problems of unfavorable large-scale construction, low efficiency, and high labor cost, and achieve the advantages of large-scale construction, high work efficiency, and high use. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and with the best embodiment.

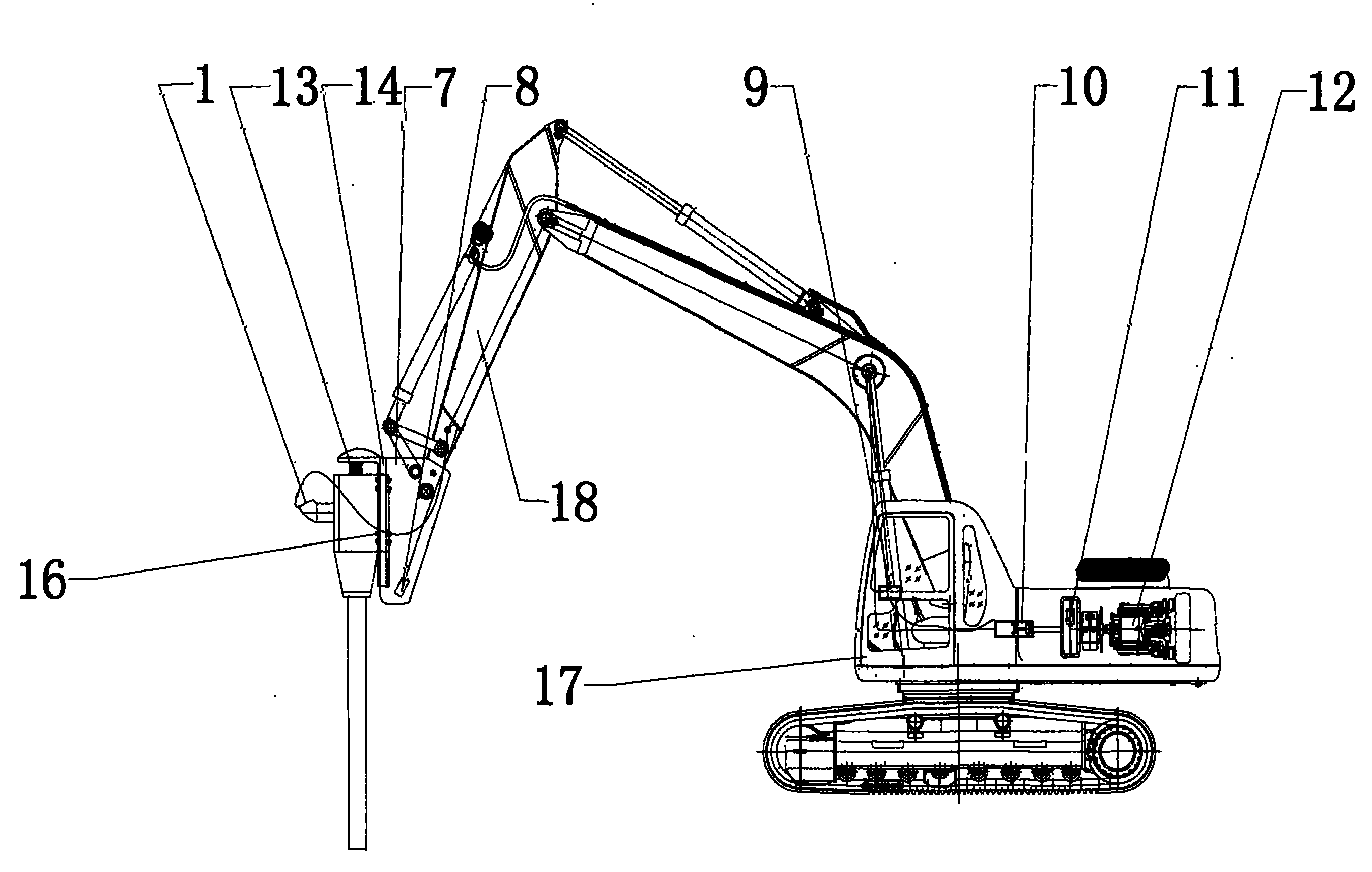

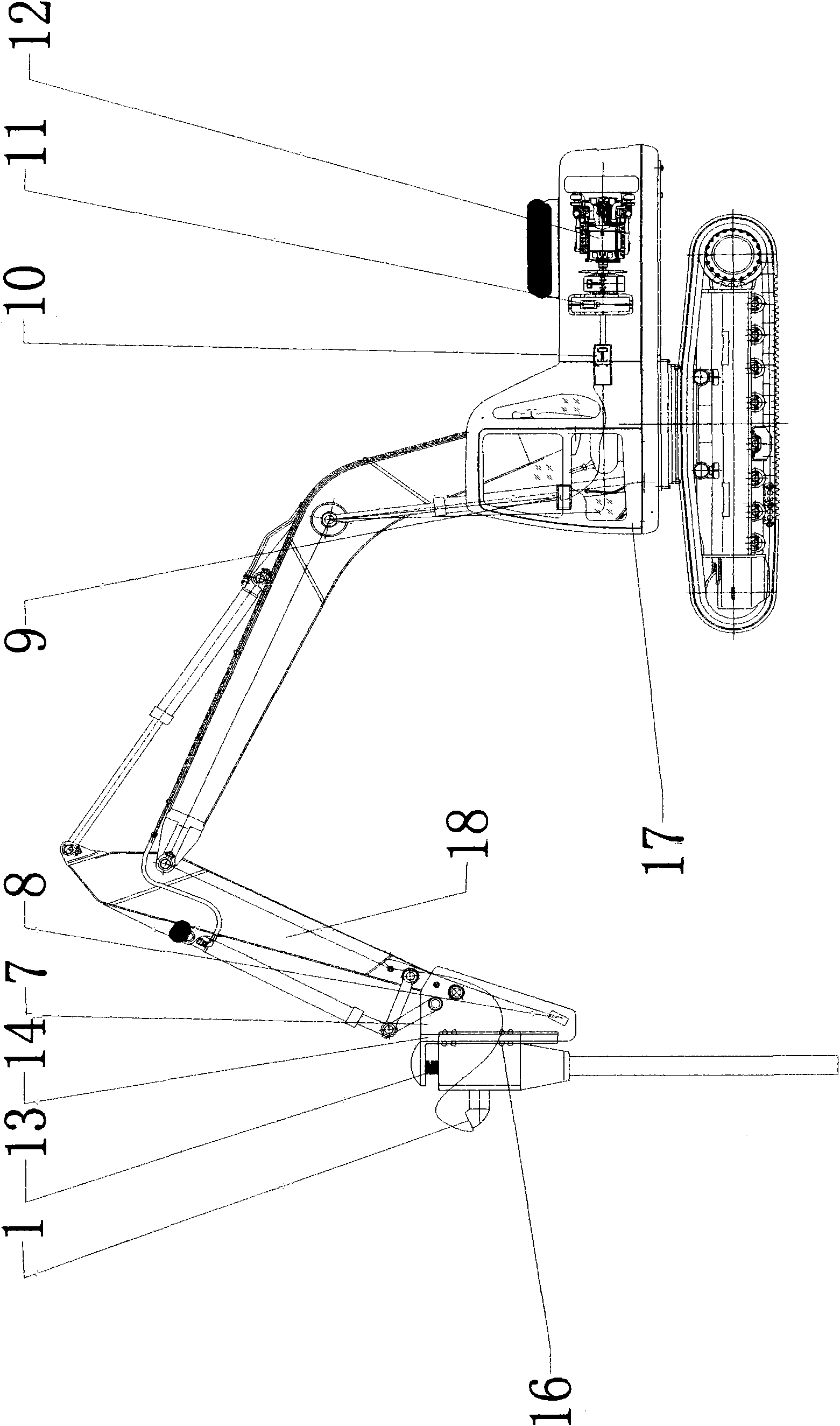

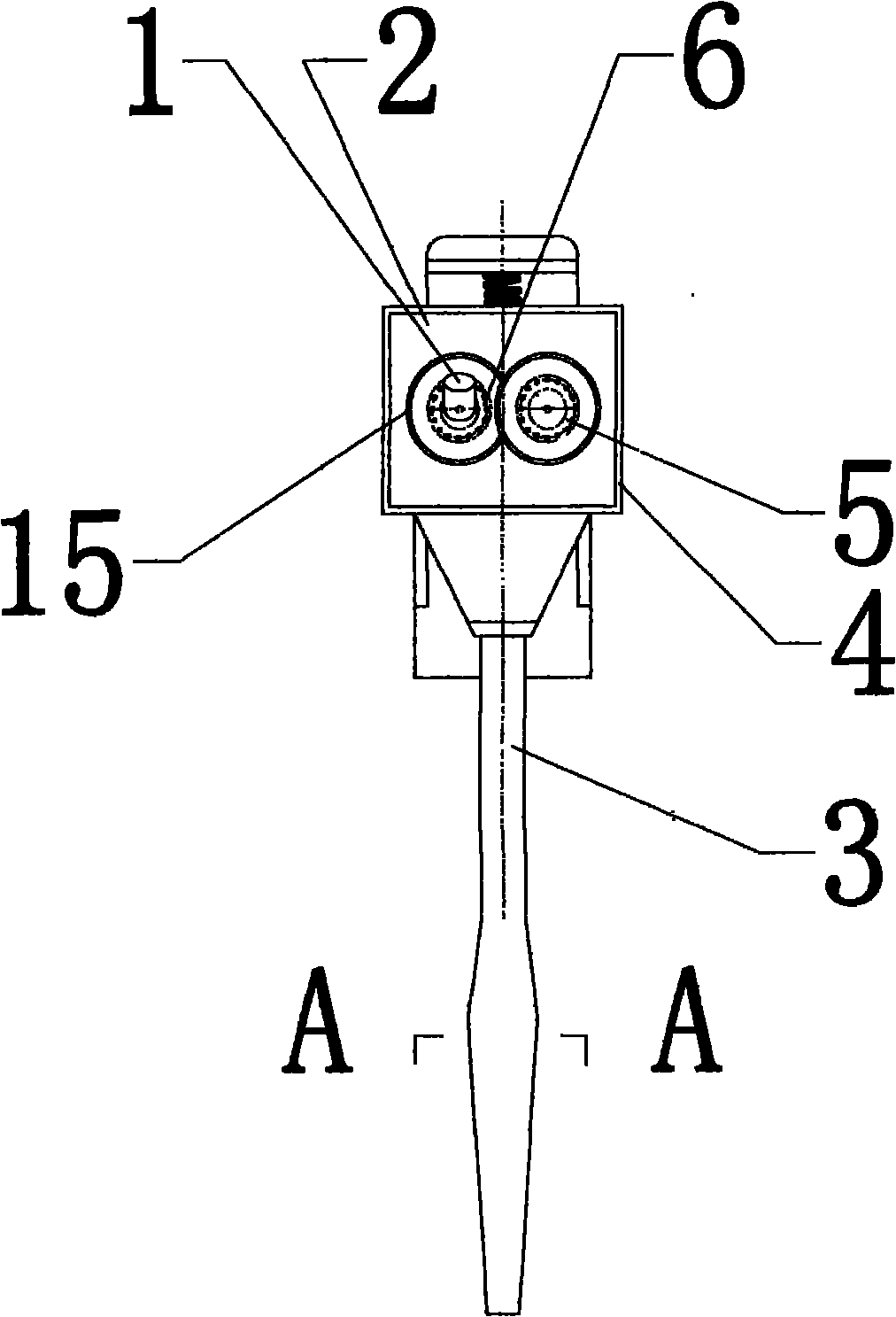

[0021] Referring to Figures 1-5, the hydraulic vibrating rock splitter includes an excavator body 17, an excavator arm 18 installed on the excavator body 17, a hydraulic drive system, a vibrator, a coupling mechanism, and a control system. The hydraulic drive system is composed of a hydraulic motor 1 , a hydraulic pump 11 , and an electronically controlled hydraulic distribution valve 10 . The hydraulic drive system is composed of a hydraulic motor 1, a hydraulic pump 11, and an electronically controlled hydraulic distribution valve 10. The engine 12 is connected to the driving hydraulic pump 11, the driving hydraulic pump 11 is connected to the electronically controlled hydraulic distribution valve 10, and the electronically controlled hydraulic distribution valve 10 is connected to the hydraulic motor. 1. The exciter 2 is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com