Device and method for automatically adjusting loaded mass center of platform surface of single-shaft air floatation rotating platform

An air-floating turntable and automatic adjustment technology, which is applied to measuring devices, static/dynamic balance tests, and machine/structural component tests, can solve the problems of low adjustment efficiency and low accuracy of adjustment results, and achieve high adjustment efficiency , low cost, precise adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

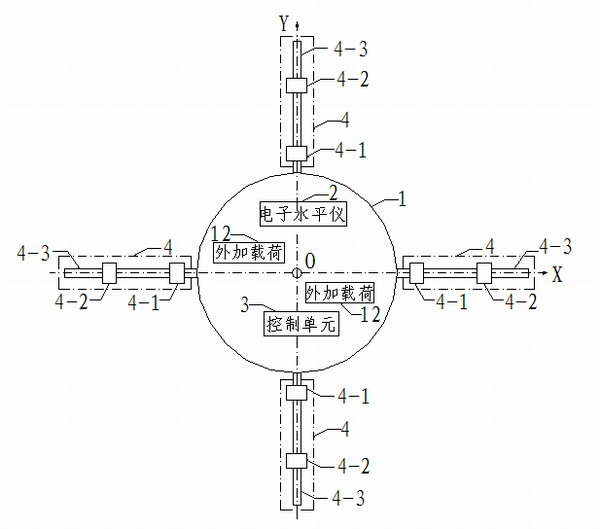

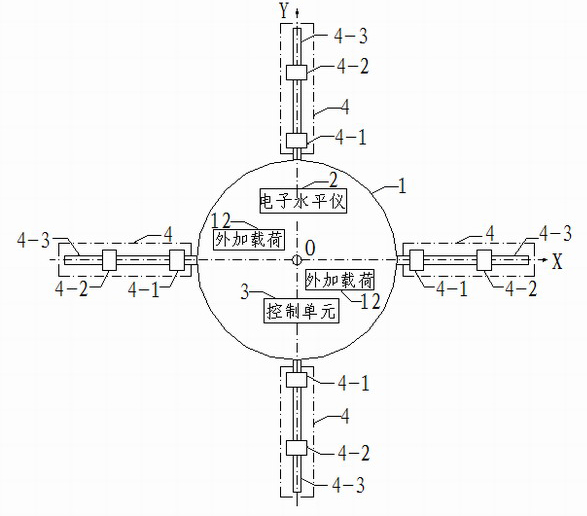

[0016] Specific Embodiments 1. This specific embodiment is described in conjunction with FIG. 1 and FIG. 2. The device for automatically adjusting the center of mass after the surface of a uniaxial air-floating turntable is loaded with an external load includes a uniaxial air-floating turntable 1, and it also includes an electronic level 2 and a control module. 3 and four identical quality adjustment devices 4, take the center of the single-axis air bearing turntable 1 as the origin, take the horizontal direction as the X axis, and take the vertical and horizontal direction as the Y axis to establish a plane Cartesian coordinate system XOY; the four The mass adjustment device 4 is distributed on the positive semi-axis of X, the negative semi-axis of Y, the negative semi-axis of X and the positive semi-axis of Y, and they are symmetrical in pairs, that is, the positive semi-axis mass adjustment device of X and the positive semi-axis of Y respectively. Negative half-axis quality ...

specific Embodiment approach 2

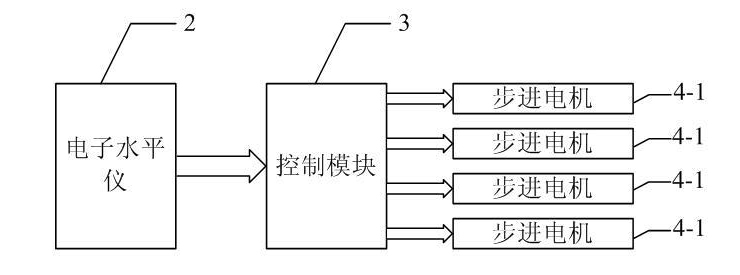

[0017] Embodiment 2. The difference between this embodiment and the device for automatically adjusting the center of mass of the uniaxial air-floating turntable table top described in Embodiment 1 is that the control module 3 includes a single-chip microcomputer and a stepping motor driver, and the single-chip microcomputer The signal input end is the signal input end of the control module 3, the signal output end of the single-chip microcomputer is connected with the signal input end of the stepper motor driver, and the four drive signal ends of the stepper motor driver are the drive signal output ends of the control module 3.

[0018] In this embodiment, the operating power supply voltages of the single-chip microcomputer and the stepper motor driver in the control module 3 are both +5v, which are provided by the power supply of the simulation system on the table of the single-axis air-floating turntable 1 .

specific Embodiment approach 3

[0019] Specific embodiment three, the difference between this specific embodiment and the device for automatically adjusting the center of mass after the uniaxial air-floating turntable table top is added load described in specific embodiment two is that it also includes the RS232 bus, between the electronic level 2 and the single-chip microcomputer Connection via RS232 bus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com