Hollow sample making device

A kind of sample preparation device and hollow technology, applied in the field of hollow sample preparation device, can solve the problems of affecting the normal work of others, noise pollution, poor comparability of test results, etc., achieve a good man-machine exchange interface, ensure flatness, intuitive and easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

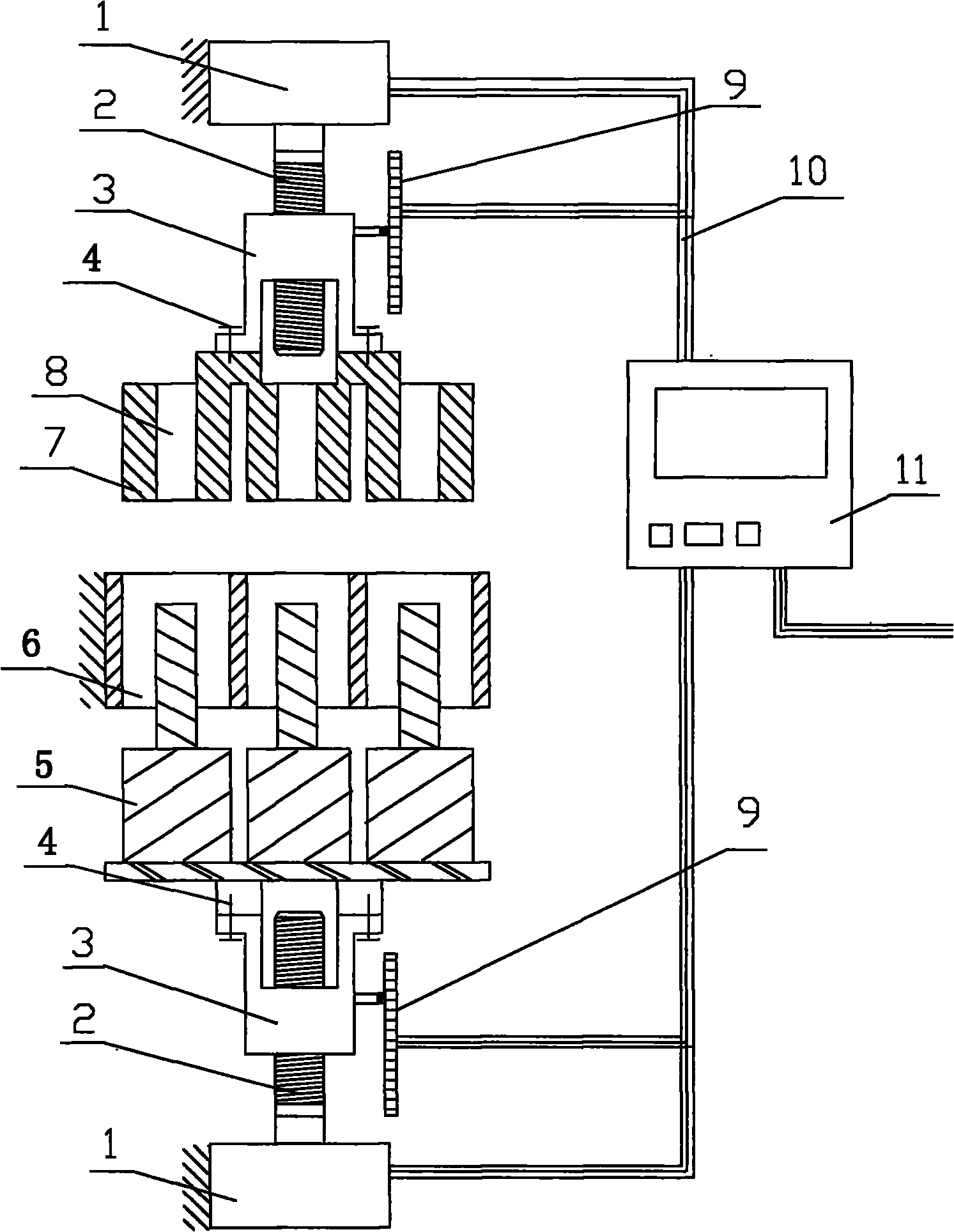

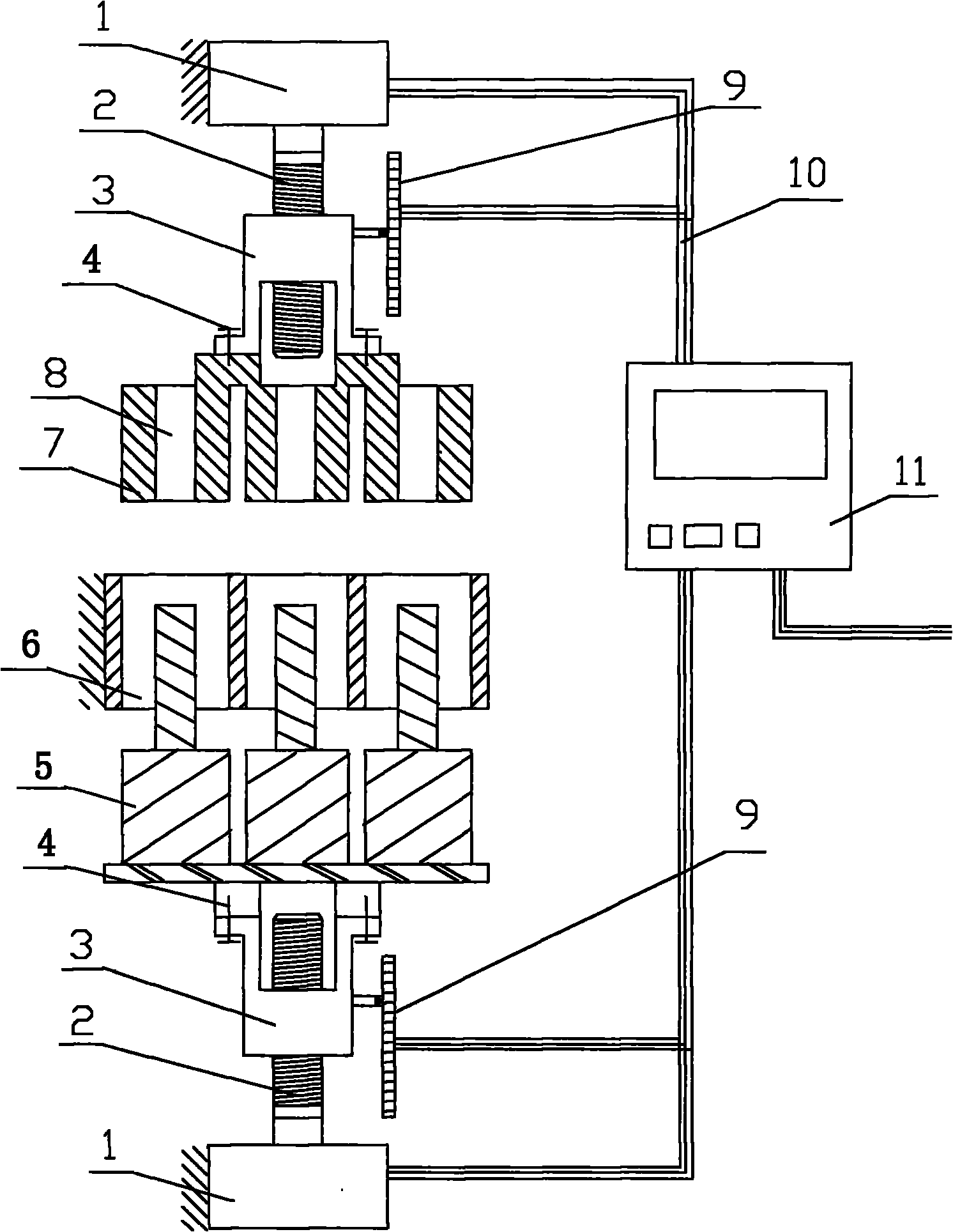

[0025] Embodiment 1: The overall structure of the hollow sample sample preparation instrument of the present invention is shown in Figure 1, including an indenter mechanism, a transmission mechanism, and a controller. The indenter mechanism is composed of a lower die head 5, an outer die head 6 and an upper die head 7. Two servo motors are selected as the transmission mechanism 1, the transmission shafts of the two servo motors are symmetrically connected to the two screw rods 2, and the two screw rods are respectively connected to the two nut parts 3, and the two nut parts are respectively fastened to the lower die head 5 and the Upper die head 7 is equipped with position sensor 9 on two nut parts 3, two servo motors and position sensor are connected with controller 11 by cable 10, two servo motors and outer mold 6 are installed on the fixture respectively.

Embodiment 2

[0026] Embodiment 2: the use steps of the hollow sample sample preparation instrument of embodiment 1 of the present invention:

[0027] (1) Turn on the power supply of the controller 11, and set various parameters;

[0028] (2) The servo motor as the transmission mechanism starts to run, and drives the screw mandrel 2 and the lower die head 5 to move upward until the ladder plane in the middle of the lower die head coincides with the lower plane of the adventitia cavity, and pauses;

[0029] (3) Load the material to be pressed;

[0030] (4) The upper die head 7 starts to move downwards, and when the lower plane of the upper die head coincides with the upper plane of the adventitia cavity, the lower die head also starts to move at the same setting speed until the upper die head and the lower die head The distance is shortened to the set value. And automatically execute the set compaction times and holding time in a cycle;

[0031] (5) The upper die head retreats to the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com