Active element array substrate and manufacturing method thereof

A technology of active components and array substrates, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, and electric solid-state devices. The effect of sexual potency

Inactive Publication Date: 2010-08-25

AU OPTRONICS CORP

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when the copper metal is manufactured, copper oxide will be formed on the surface of the copper metal. Since the etching rate of the copper oxide on the copper surface is different from that of copper, it is easy to cause disconnection in the etching manufacturing process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

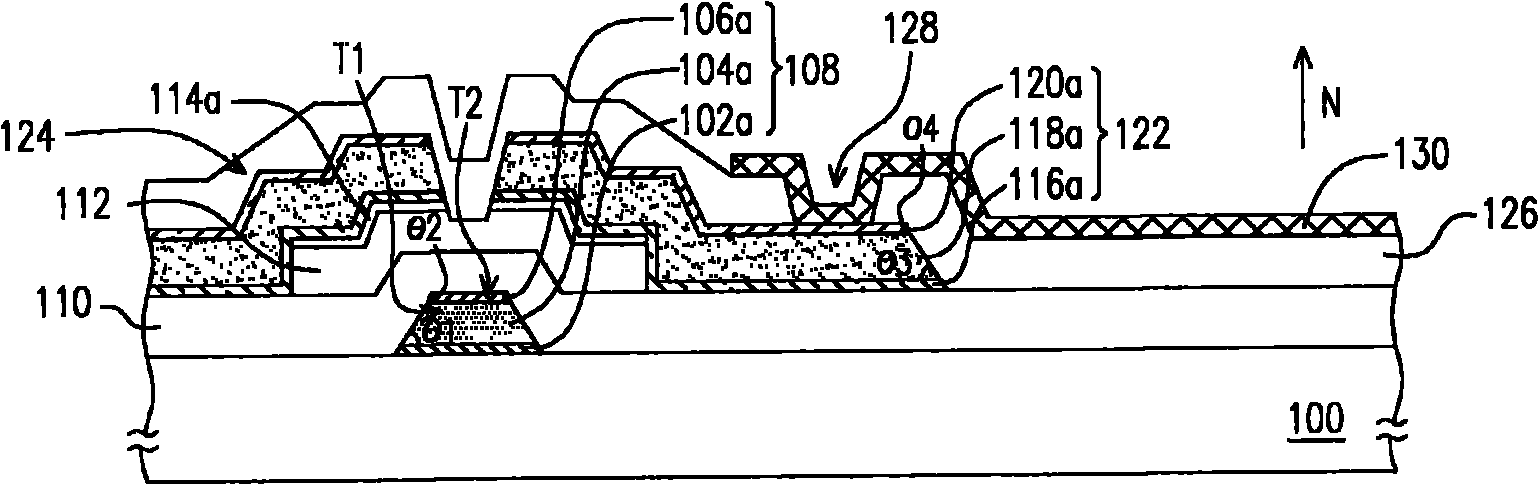

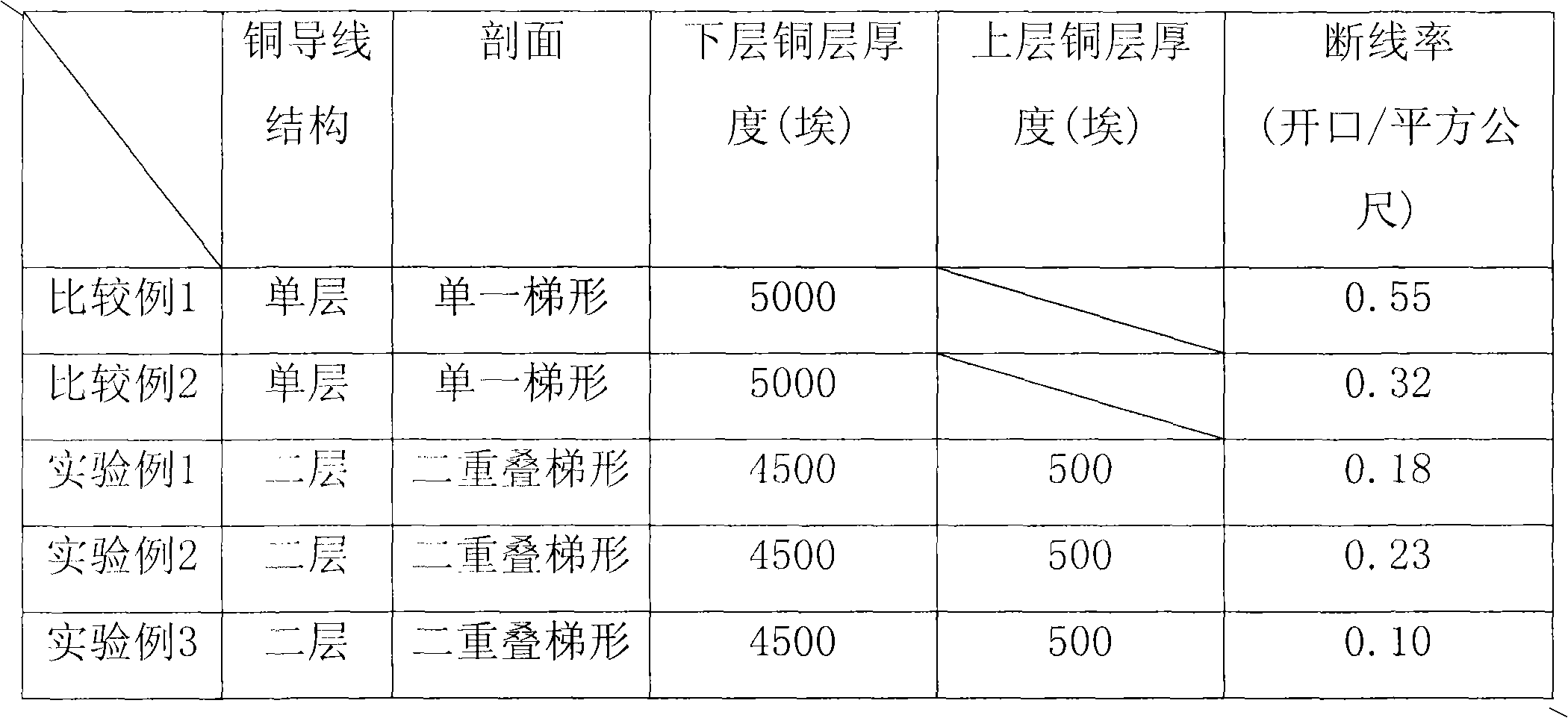

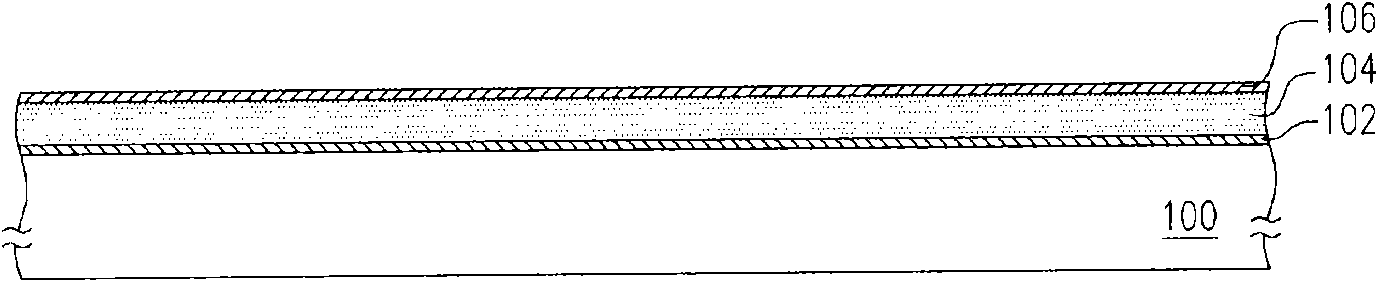

The embodiment of the invention provides an active element array substrate and a manufacturing method thereof. The active element array substrate is provided with at least one pattern conducting layer; the pattern conducting layer comprises a copper layer; the section of the copper layer in the normal direction parallel to the copper layer consisting of a first trapezoid and a second trapezoid overlapped on the trapezoid; and the angle difference between the base angle of the first trapezoid and the base angle of the second trapezoid is an acute angle between 5 and 30 degrees. Due to the embodiment of the invention, better electrical efficiency can be provided, and the line broken ratio can be effectively improved.

Description

technical field The present invention relates to an active device array substrate (Active Device Array Substrate), in particular to an active device array substrate with a copper conductive layer. Background technique As the size of the thin film transistor liquid crystal display (TFT-LCD) panel becomes larger and larger, it is accompanied by the resistance capacitance (RC) delay effect caused by the resistance of the metal wire not being low enough, thus causing distortion and distortion of the signal during transmission. , which affects the presentation of panel quality. Using a single-layer copper metal with low resistance to form a metal wire can effectively reduce the RC delay effect. However, when the copper metal is manufactured, copper oxide will be formed on the surface of the copper metal. Since the etching rate of the copper oxide on the copper surface layer is different from that of copper, the problem of disconnection is likely to occur during the etching manuf...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L23/14H01L23/48H01L23/525H01L23/535H01L21/768

Inventor 陈柏林林致远林瑜旻林俊男

Owner AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com