Active element array substrate and manufacturing method thereof

A technology of active components and array substrates, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, and electric solid-state devices. The effect of oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

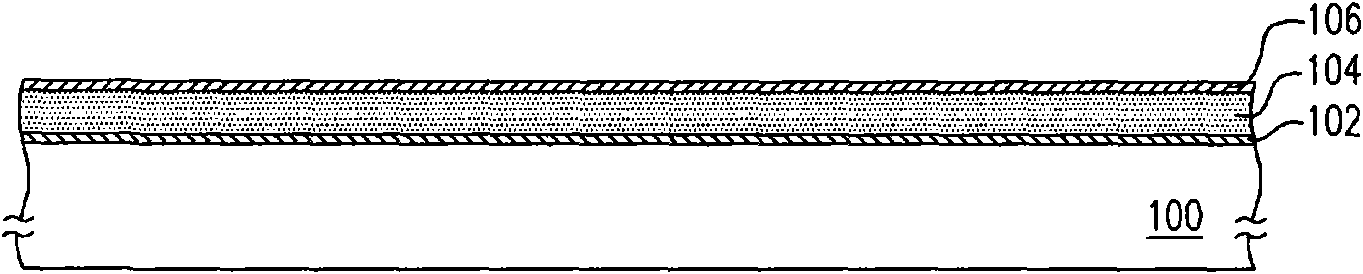

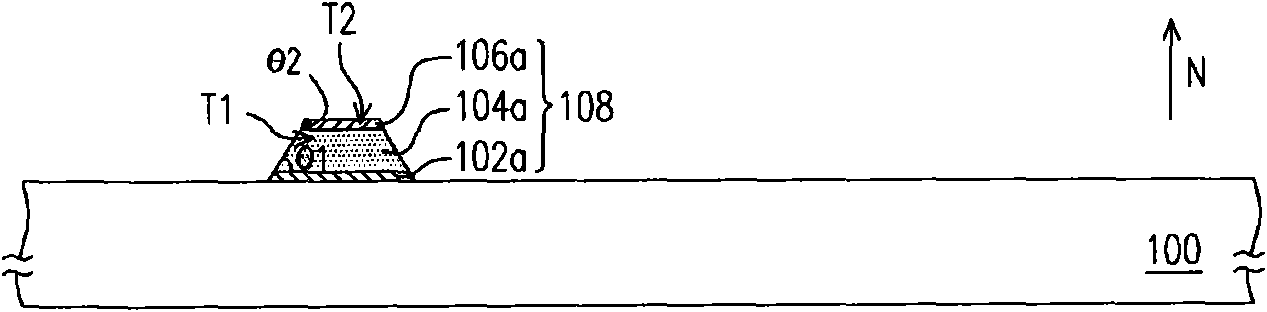

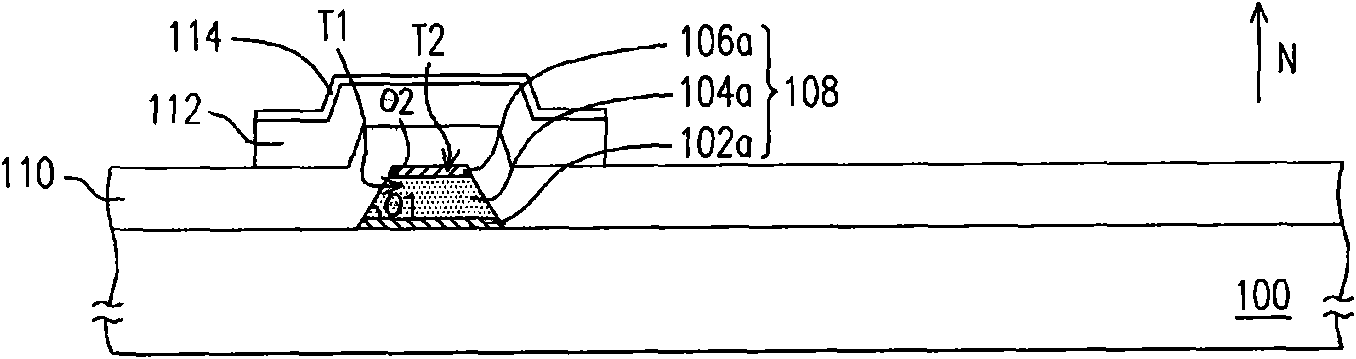

[0040] Figure 1A to Figure 1G It is a cross-sectional view of a manufacturing process of an active device array substrate according to an embodiment of the present invention. figure 2 for Figure 1E A cross-sectional view of the patterned conductive layer 122 in another cross-sectional direction, where figure 2 The section direction of Figure 1E The section directions are perpendicular to each other.

[0041] First, please refer to Figure 1A , Provide a substrate 100. The material of the substrate 100 is, for example, a transparent material, an opaque material, a flexible material, or a combination of the foregoing materials.

[0042] Then, a barrier layer 102 can be selectively formed on the substrate 100. The material of the barrier layer 102 is, for example, at least one selected from the group consisting of molybdenum, molybdenum alloy, titanium, titanium alloy, aluminum alloy, and copper alloy. The formation method of the barrier layer 102 is, for example, a physical vapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com