Catalyst for preparing vinylidene chloride by trichloroethane gas-phase catalytic cracking and preparation method thereof

A catalytic cracking, trichloroethane technology, applied in physical/chemical process catalysts, dehydrohalogenation preparation, chemical instruments and methods, etc., can solve problems such as unsatisfactory selectivity, achieve difficult surface area carbon deactivation, and prolong life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

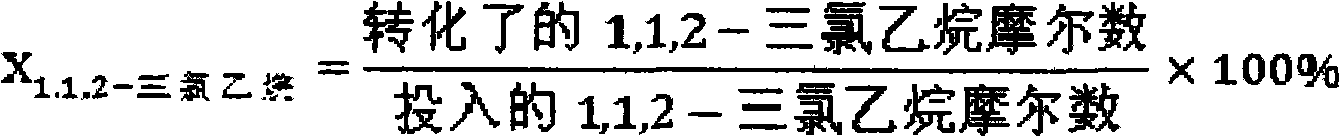

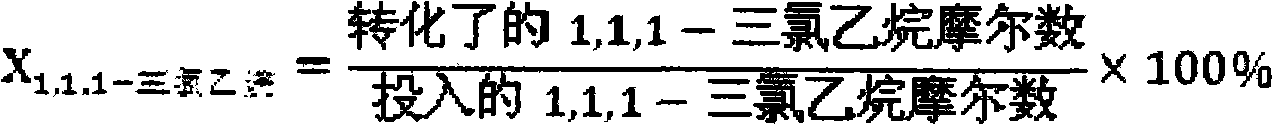

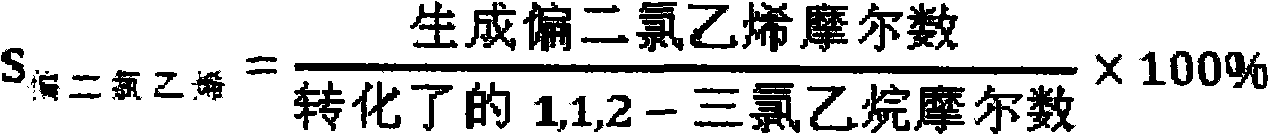

Image

Examples

Embodiment 1

[0032] (1) cesium nitrate is mixed with the saturated solution under 80 ℃;

[0033] (2) At 90°C, the solution obtained in step (1) was impregnated on the carrier by an equal-volume impregnation method, and dried at 70°C under a vacuum of 0.1 Pa for 28 hours;

[0034] The equal-volume impregnation method is a conventional method for preparing catalysts, such as the method provided in the document "Introduction to Catalyst Engineering" (Wang Shangdi, Sun Junquan. Chemical Industry Press. 2001.55).

[0035] The carrier is a macroporous and mesoporous composite silica-alumina molecular sieve. The document "Synthesis and Characterization of a Hierarchically Ordered Porous Silica Material" (T.Sen.Synthesis and Characterization of Hierarchically Ordered Porous SilicaMaterials[J]Chem.Materials[J]Chem.Materials .2004, 16, 2044-2054) reported method, there is a regular macropore structure with a pore size of 100-500nm inside the molecular sieve, and a mesoporous structure with a pore si...

Embodiment 2

[0042] (1) Potassium nitrate is mixed with the saturated solution under 80 ℃;

[0043] (2) At 95°C, impregnate the solution obtained in step (1) on the carrier by an equal-volume impregnation method, and dry at 50°C for 20 hours under a vacuum of 100 Pa;

[0044] The weight ratio of the solution of the step (1) and the carrier is: the solution of the step (1): carrier=1:? ;

[0045] The carrier is a macroporous and mesoporous composite silica-alumina molecular sieve. The document "Synthesis and Characterization of a Hierarchically Ordered Porous Silica Material" (T.Sen.Synthesis and Characterization of Hierarchically Ordered Porous SilicaMaterials[J]Chem.Materials[J]Chem.Materials .2004, 16, 2044-2054) reported method, there is a regular macropore structure with a pore size of 100-500nm inside the molecular sieve, and a mesoporous structure with a pore size of 3-10nm exists on the macropore wall, and the porosity is greater than 74.05%. , and the molecular sieve with all the...

Embodiment 3

[0053] (1) Rubidium nitrate is prepared into a saturated solution at 80°C;

[0054](2) At 80°C, the solution obtained in step (1) was impregnated on the carrier by an equal-volume impregnation method, and dried at 60°C for 24 hours under a vacuum of 50 Pa;

[0055] The carrier is a macroporous and mesoporous composite silica-alumina molecular sieve. The document "Synthesis and Characterization of a Hierarchically Ordered Porous Silica Material" (T.Sen.Synthesis and Characterization of Hierarchically Ordered Porous SilicaMaterials[J]Chem.Materials[J]Chem.Materials .2004, 16, 2044-2054) reported method, there is a regular macropore structure with a pore size of 100-500nm inside the molecular sieve, and a mesoporous structure with a pore size of 3-10nm exists on the macropore wall, and the porosity is greater than 74.05%. , and the molecular sieve with all the channels connected.

[0056] (3) The product obtained in step (2) was roasted at 550° C. for 36 hours;

[0057] (4) pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com