Method for even hydrogenation of NaZn13 structured rare earth-iron cobalt silicon material

A technology of iron-cobalt-silicon and rare earths, which is applied in the direction of magnetic materials, inorganic materials, electrical components, etc., can solve the problems that do not involve the uniformity of rare earth-iron-cobalt-silicon compounds, reduce preparation costs, reduce equipment maintenance, and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] will have NaZn 13 Structure LaFe 11.5 Si 1.5 The compound was placed in a closed hydrogen annealing furnace, and the vacuum was evacuated to 6×10 -1 Pa, heated to 150°C to 650°C, hydrogen at an atmospheric pressure, hydrogenated for 2 hours to obtain LaFe 11.5 Si 1.5 Hydride. Such as Figure 2 to Figure 9 Shown:

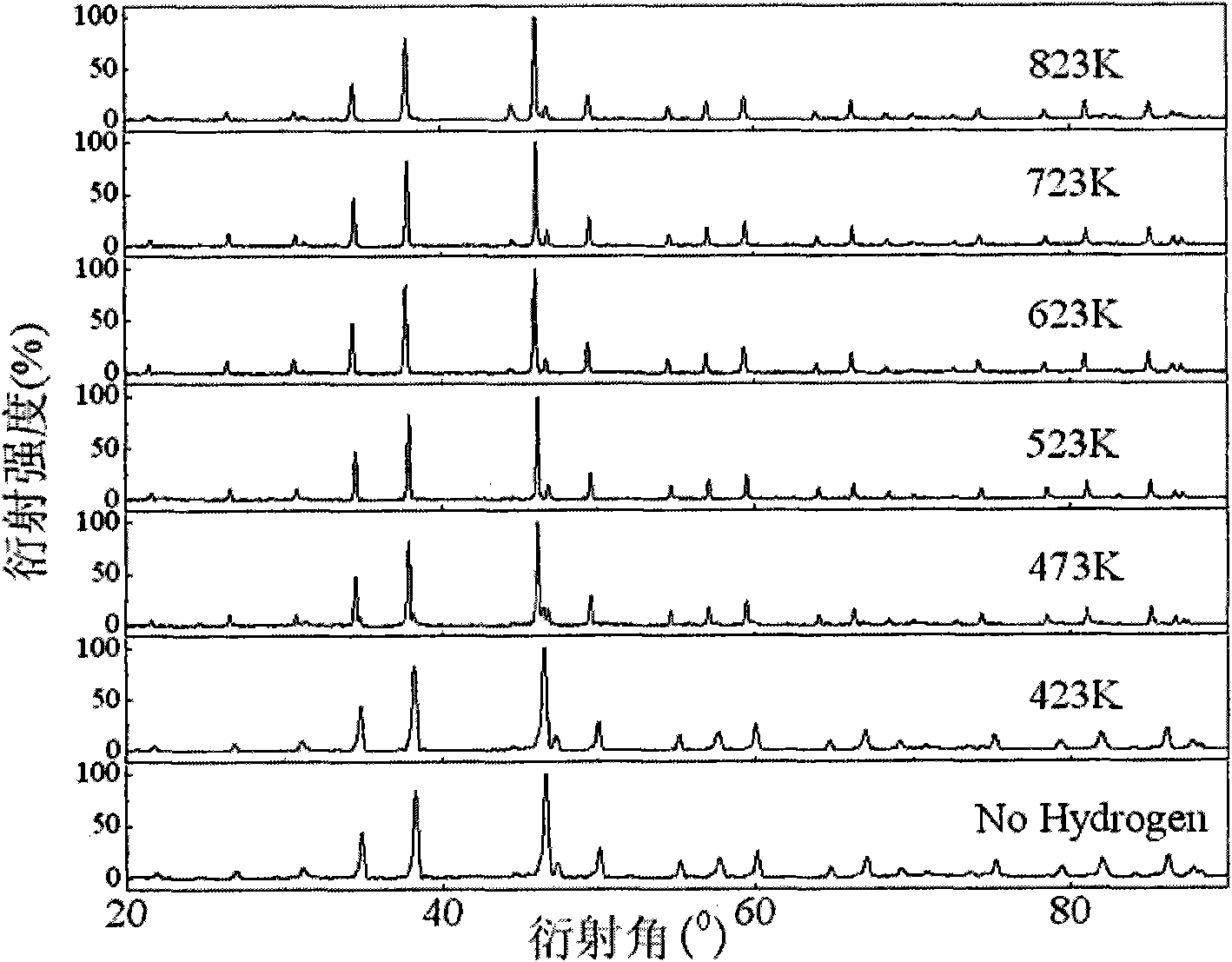

[0038] figure 2 It represents the X-ray diffraction pattern of the hydride obtained by hydrogenating the compound at various temperatures, wherein the abscissa is the diffraction angle, and the ordinate is the diffraction intensity. It can be seen from the figure that when the hydrogenation temperature is 150°C, LaFe 11.5 Si 1.5 The X-ray diffraction pattern of the compound and the original LaFe 11.5 Si 1.5 The ratio of the compound does not change, indicating that at 150 °C LaFe 11.5 Si 1.5 The compound does not absorb hydrogen. However, the X-ray diffraction patterns of hydrogenation at other hydrogenation temperatures are consistent with shif...

Embodiment 2

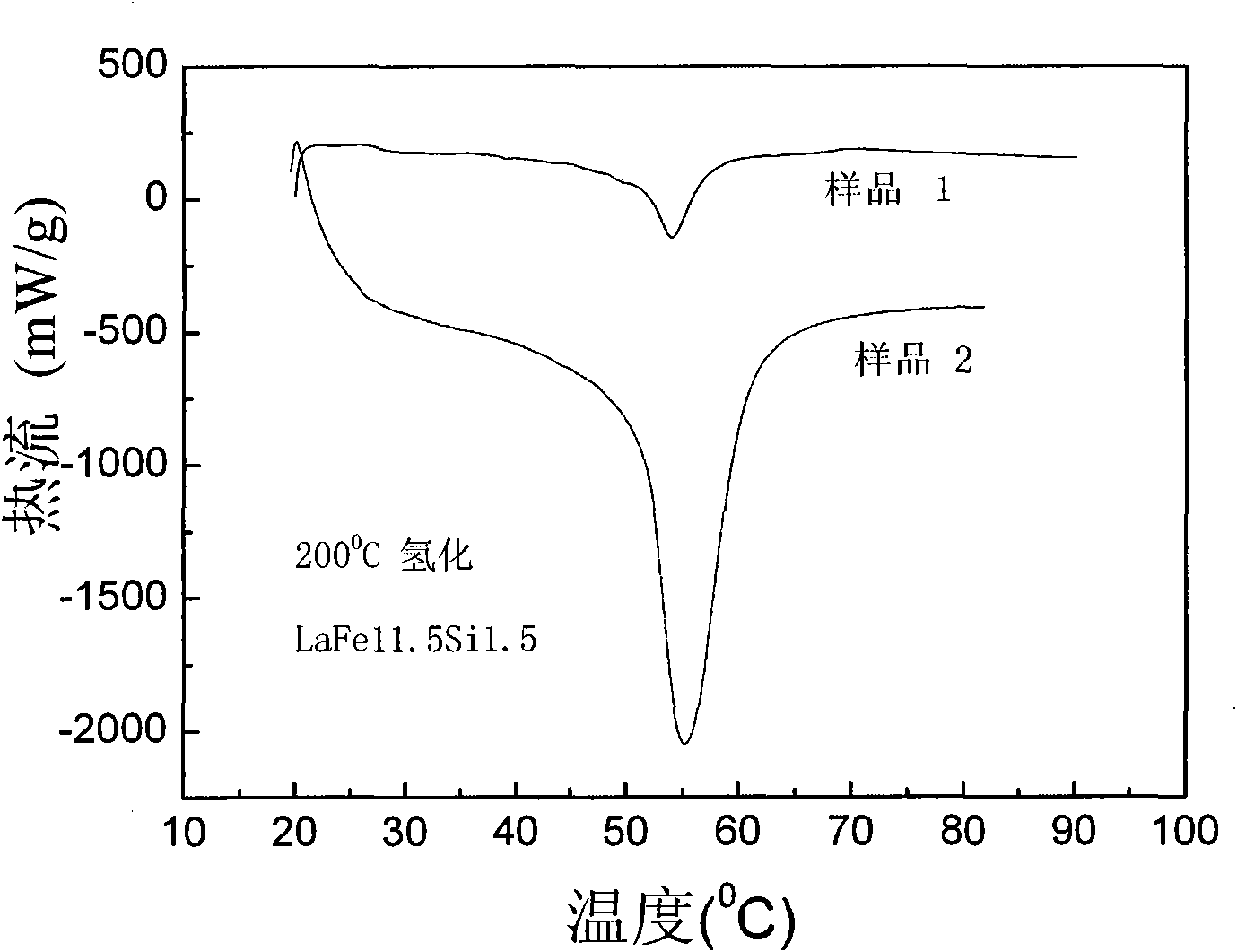

[0043] will have NaZn 13 Structure LaFe 11.6 Si 1.4 Put the compound into an open hydrogen annealing furnace, firstly pass argon gas for 30 minutes, change the atmosphere in the furnace to an argon atmosphere, and then heat it to 550°C and pass in hydrogen gas for hydrogenation, then ignite and burn hydrogen gas at the outlet of the hydrogen annealing furnace, The hydrogenation time is 2h, and the furnace is cooled after hydrogenation. Randomly selected 3 samples for DSC curve analysis, the results are as follows Figure 10 as shown, Figure 10 Be the LaFe of embodiment 2 11.6 Si 1.4 The DSC curve of the hydride; where the abscissa is temperature and the ordinate is heat flow. The exothermic peaks of the three hydride samples are sharp, with significant first-order phase transition characteristics, and the Curie temperature of the three samples is at the same temperature, indicating that hydrogen is absorbed uniformly at this time.

Embodiment 3

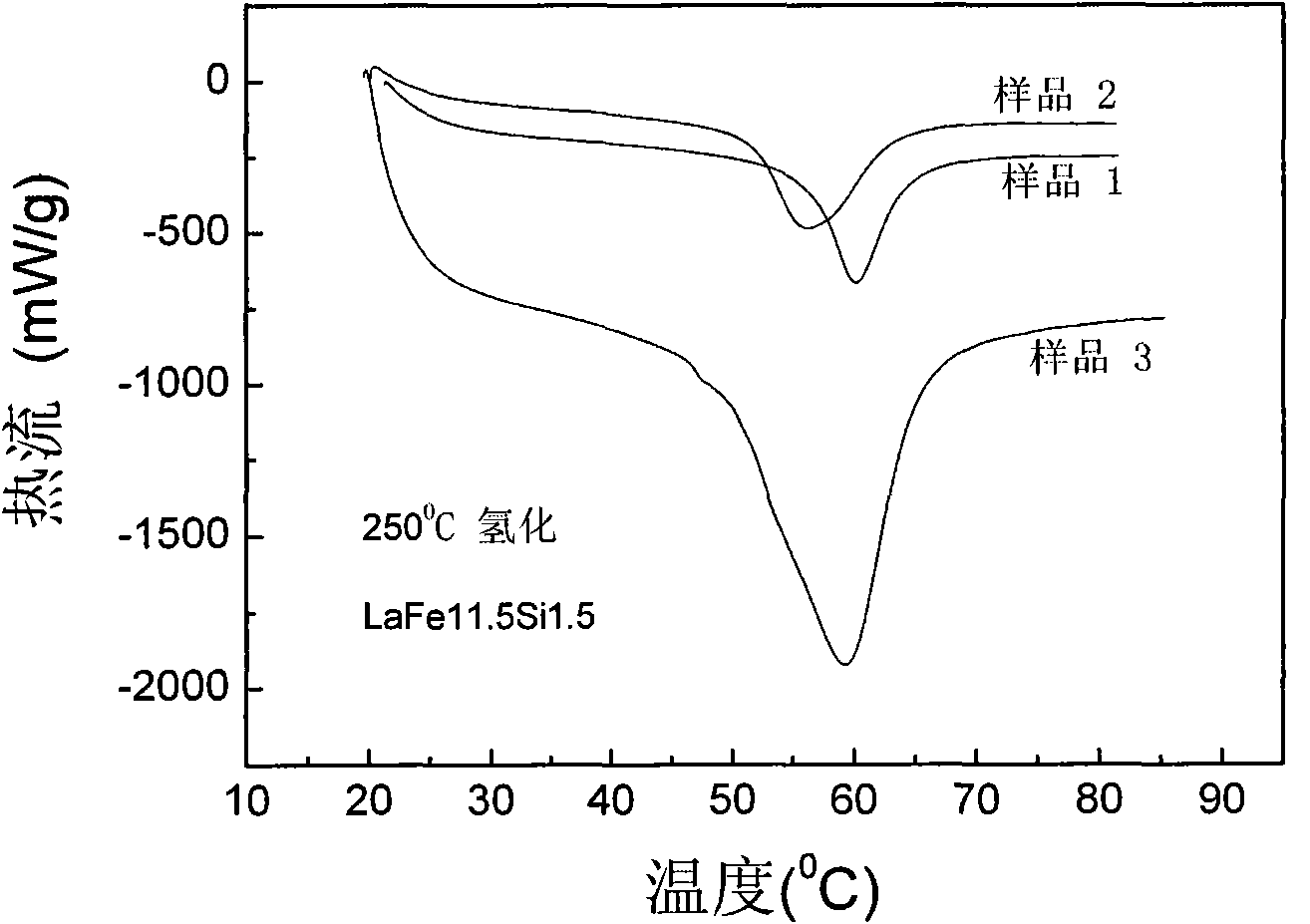

[0045] will have NaZn 13 Structure LaFe 11.6 Si 1.4 The compound was placed in a closed hydrogen annealing furnace, and the vacuum was evacuated to 6×10 -1 Pa, heated to 650°C in vacuum and held for 8 hours, then the sample was cooled to room temperature with the furnace. Then heated to 250 °C, and hydrogen gas at an atmospheric pressure was introduced, and LaFe was obtained after hydrogenation for 4 hours. 11.6 Si 1.4 Hydride. In order to test the uniformity of the activated hydrogen-charged sample, 3 small particles with a weight of about 5 mg were randomly selected in the sample for DSC measurement. The results are as follows Figure 11 shown. Figure 11 Be the LaFe of embodiment 3 11.6 Si 1.4 The DSC curve of the hydride; where the abscissa is temperature and the ordinate is heat flow. It can be seen from the figure that the peaks of the three DSC curves are relatively sharp, and the temperatures corresponding to the peaks are very close, so it can be confirmed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com