Construction technology of cross-shaped profile steel column

A construction technology and section steel technology, applied in the direction of columns, pillars, piers, etc., can solve the problems of increased workload, unfavorable effective construction, and complicated installation procedures of cross-shaped steel columns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

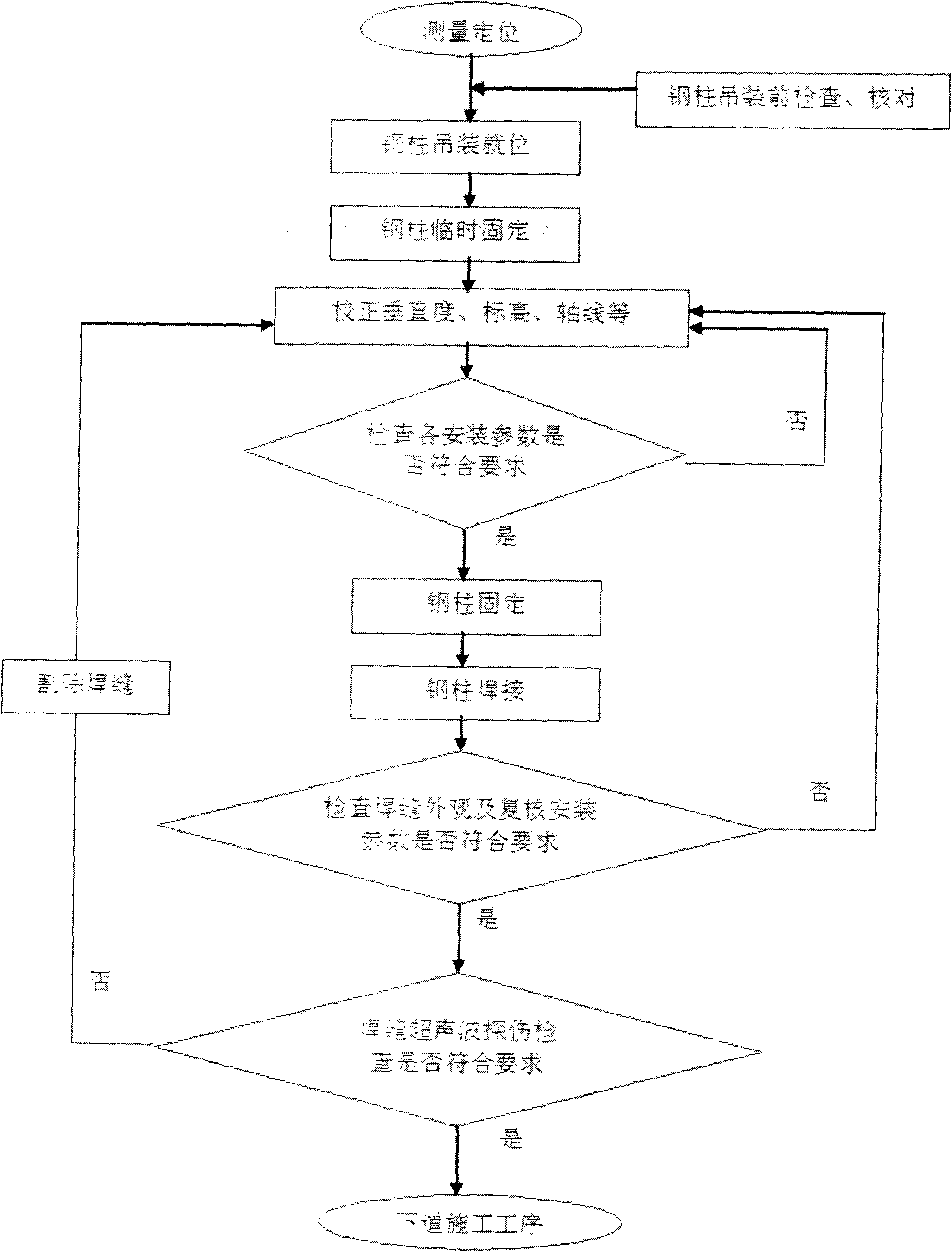

[0031] Construction technology of the present invention is as follows:

[0032] The first step is to measure and mark the cross axis of the steel column to be installed. The cross axis is used as the basis for the installation and positioning of the steel column and the control of installation parameters;

[0033] The second step is to check and check the shape and size of the steel column to be installed, the model of the steel column, and whether it is deformed during transportation;

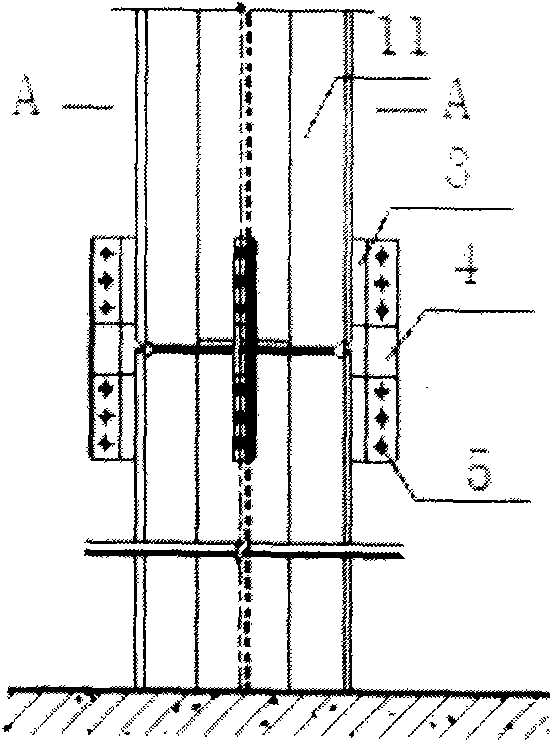

[0034] The third step is to vertically lift the verified upper and lower section steel columns to the installation site with a lifting machine, and place a circle of steel bars with a diameter of 6mm at the joint of the upper and lower section steel columns to reserve adjustment space;

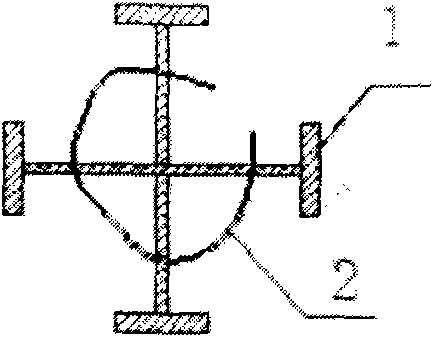

[0035] Step 4: After hoisting the upper and lower section steel columns in place, install ear plates outside the flange plates of the upper and lower section steel columns, clamp the ear plates with connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com