Diamond drill bit and manufacturing method thereof

A diamond drill bit and drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve problems such as poor adaptability, low drilling speed, and increased drilling cost, and achieve long service life, strong wear resistance, and high hardness. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Content of the present invention is as follows:

[0017] (1) Adopt a thinking and design method to improve the wear resistance of the drill bit, while improving the wear resistance of the matrix, strengthen the diameter protection effect of the working layer of the drill bit, realize the smooth operation of the drill bit and the balanced wear of the working layer, in order to improve Purpose of bit life.

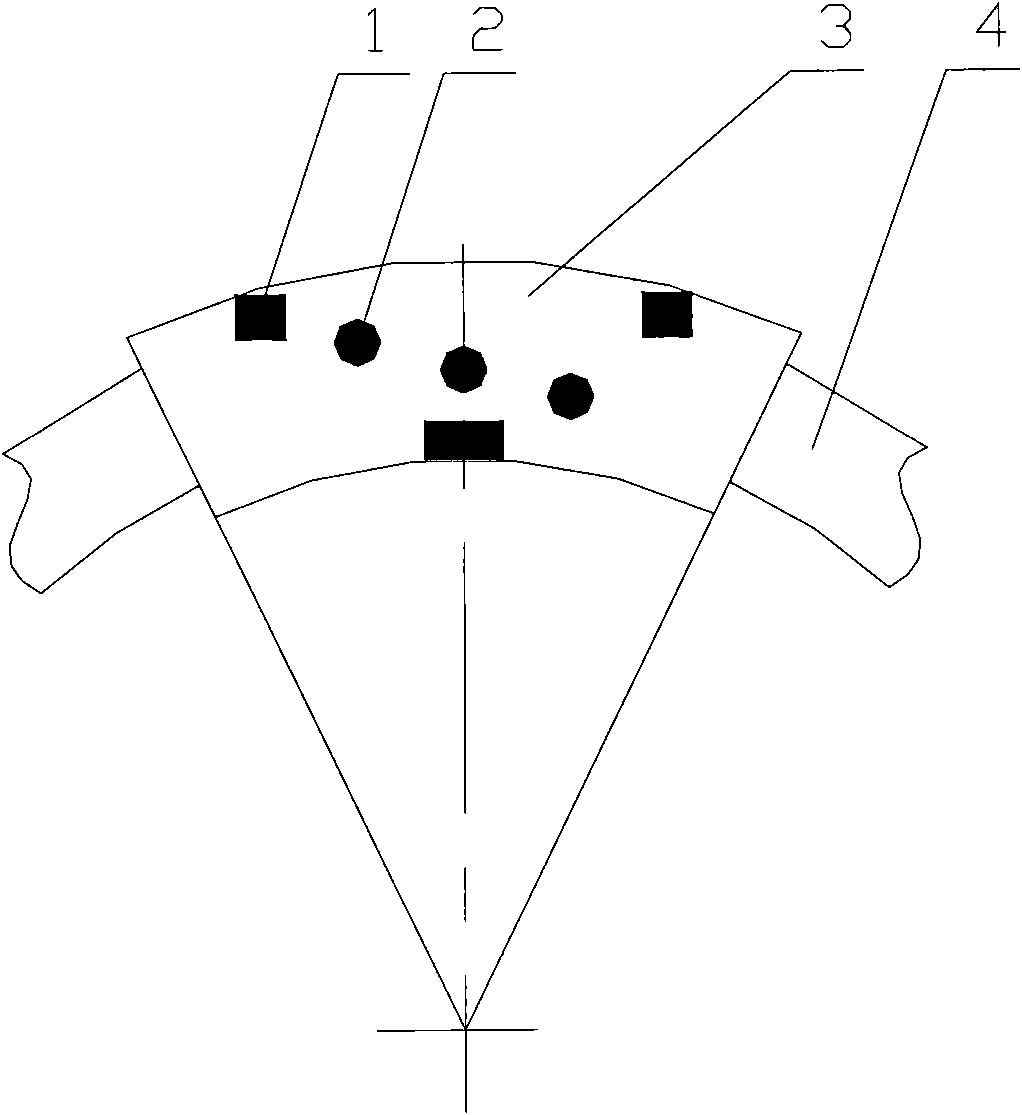

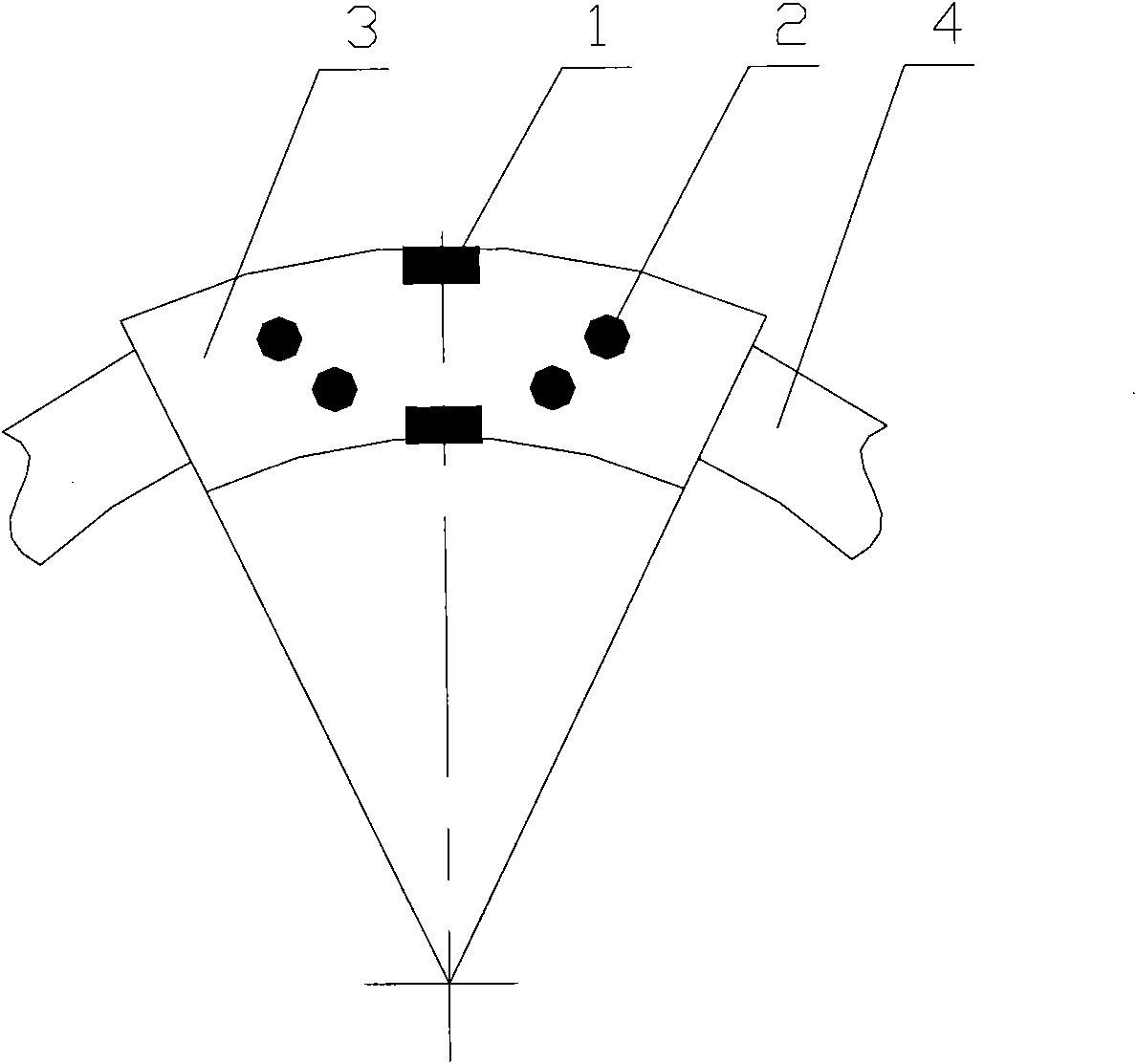

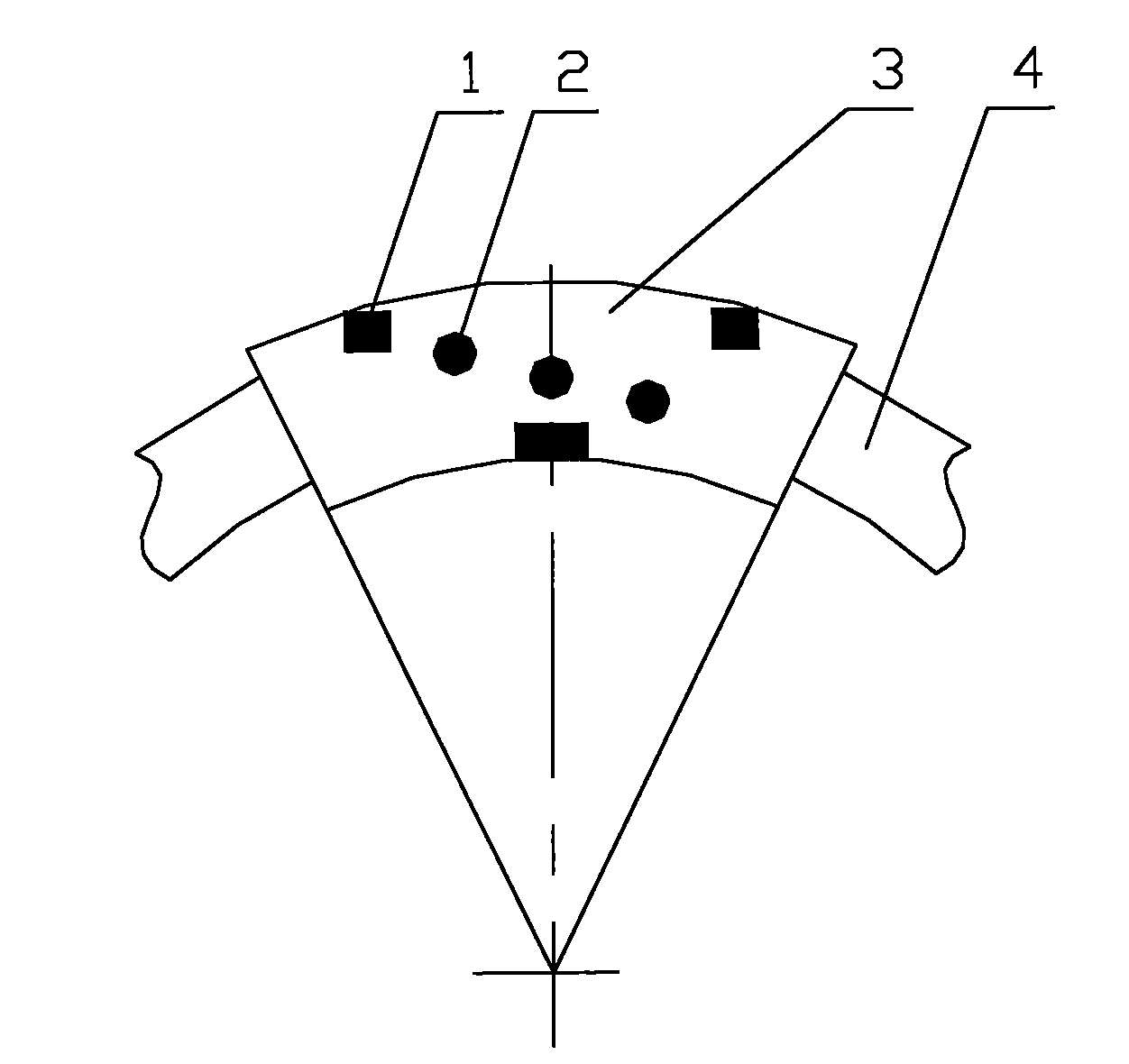

[0018] (2) On the basis of ordinary hot-pressed diamond drill bits, thermally stable polycrystals are regularly and orderly distributed and arranged in the working layer of the drill bit. Thermally stable polycrystalline not only plays the role of breaking rocks, but also strengthens the wear resistance of the drill bit and the effect of diameter protection, which effectively improves the stability and service life of the drill bit.

[0019] (3) Improving the wear resistance of the drill bit is not only the use of a high wear-resistant matrix, but often the use of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com