Gas burner

A gas burner and gas technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of large NOx emissions of flue gas components, uneven burner flame temperature field, insufficient and incomplete combustion of gas, etc. Achieve the effect of compact structure, easy maintenance and favorable utilization of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

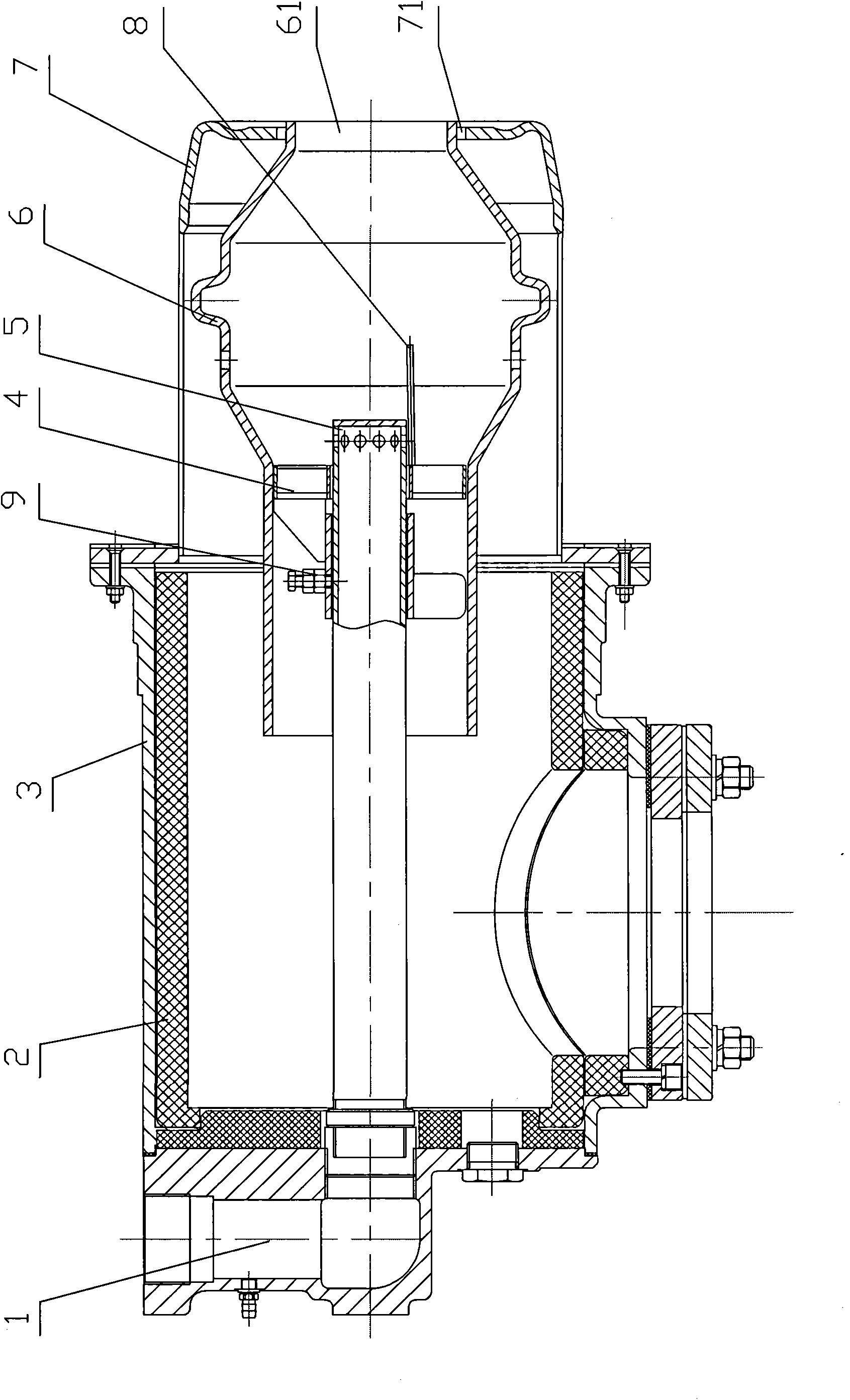

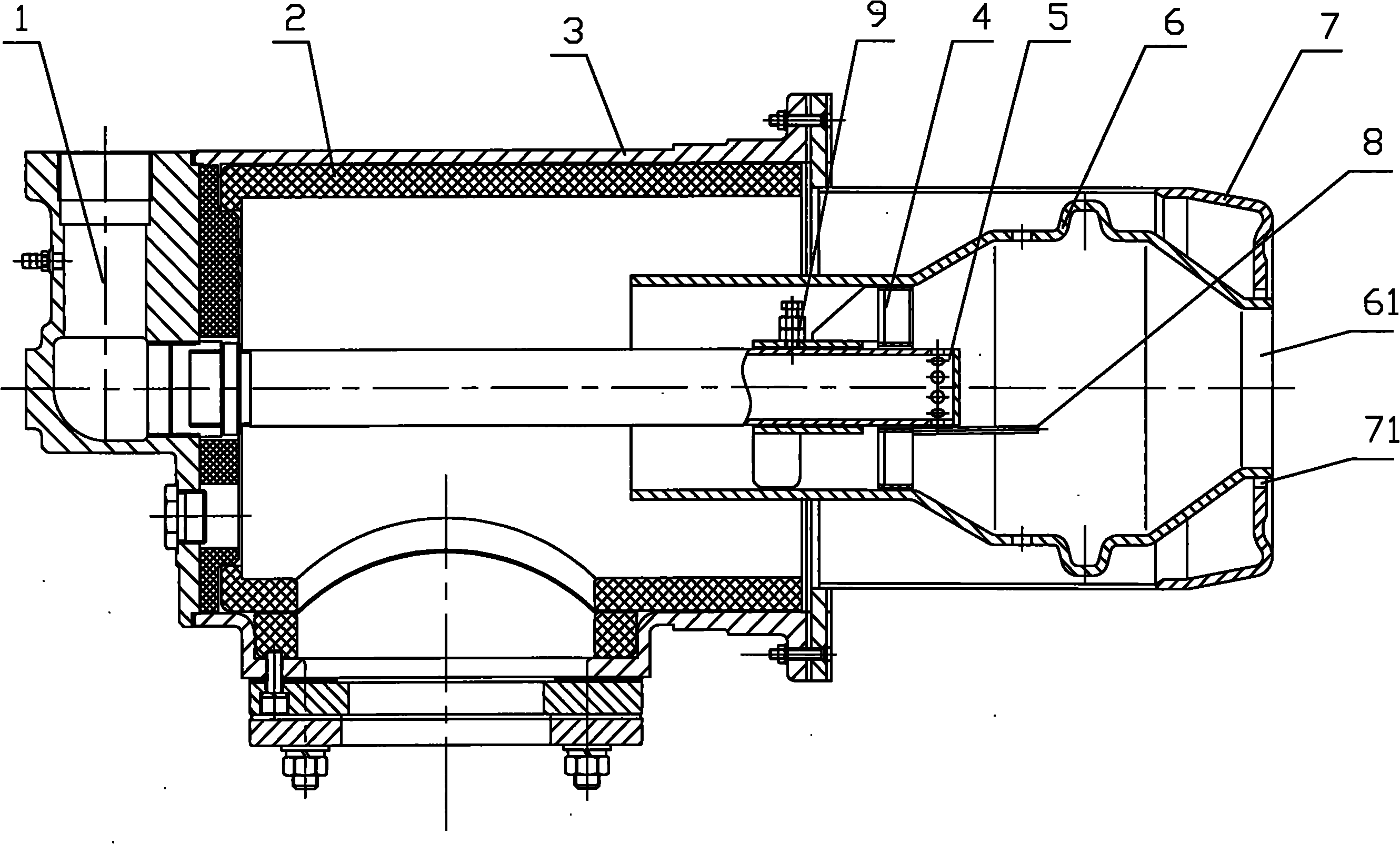

[0009] Reference figure 1 , A gas burner of the present invention includes a gas casing 1, a gas pipe 5 communicating with the gas casing 1, an air casing 3 arranged around the periphery of the gas pipe 5, and the front end of the gas pipe 5 is provided with an ignition Electrode 8, the front end of the gas pipe 5 is provided with a combustion chamber 6, the electrode 8 is located in the combustion chamber 6, the back end of the combustion chamber 6 is connected to the front end of the gas pipe 5 through a wind plate 4, the combustion chamber 6 and air The casing 3 is in communication, the front end of the combustion chamber 6 is a reduced flame nozzle 61, the periphery of the combustion chamber 6 is sleeved with an outer tube 7 communicating with the air casing 3, and the front end of the outer tube 7 surrounds the flame nozzle 61 A ring-shaped combustion-supporting air nozzle 71 is provided on the periphery of the device.

[0010] The above technical solution can also have the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap