Automatic control device of infrared ray burner

An automatic control device and an infrared burner technology, applied in the direction of combustion method, combustion control, fuel supply adjustment, etc., can solve problems such as low thermal efficiency of the burner, non-operation, unstable gas pressure, etc., and achieve high cost savings, The best energy-saving effect and the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

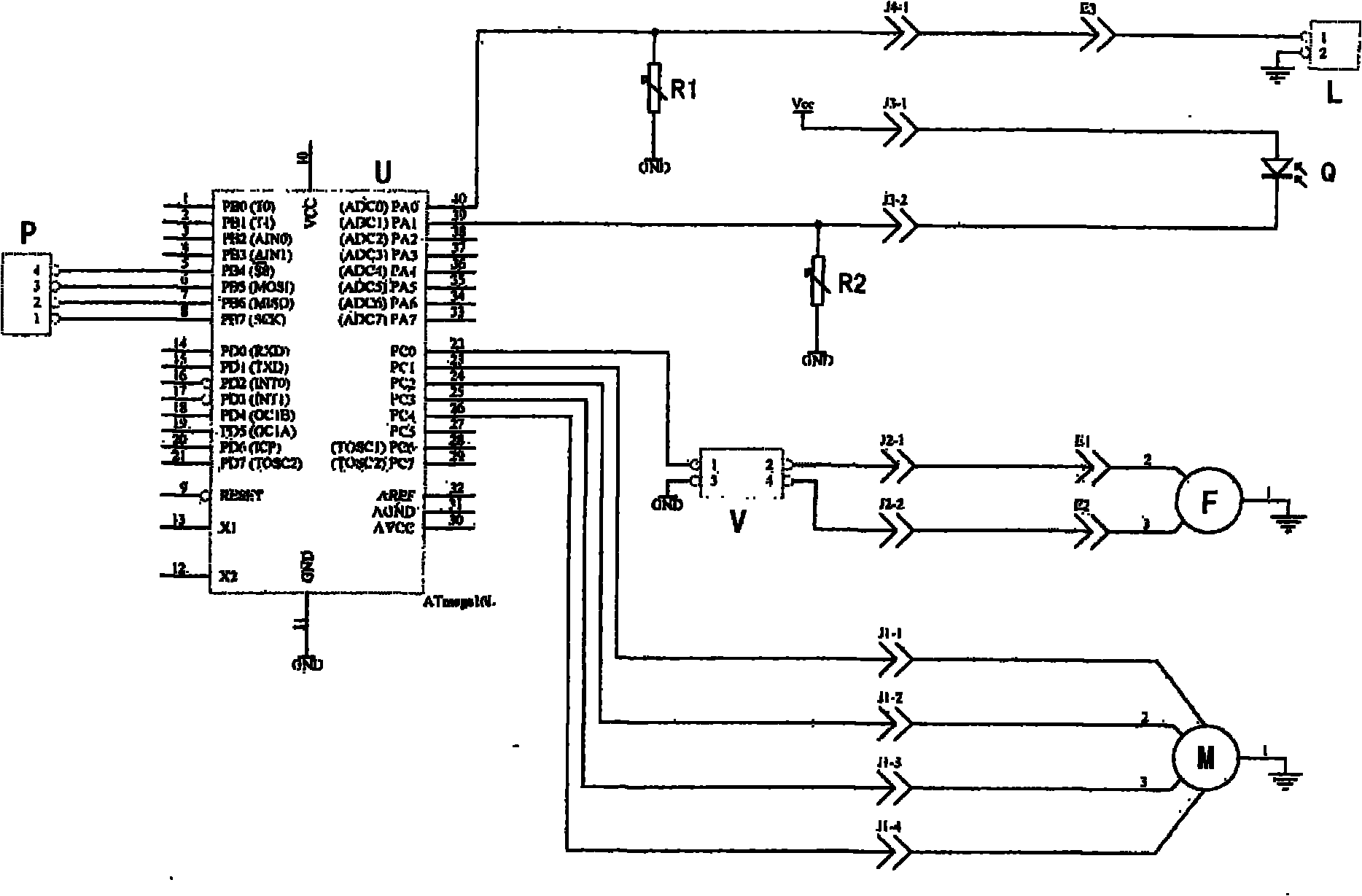

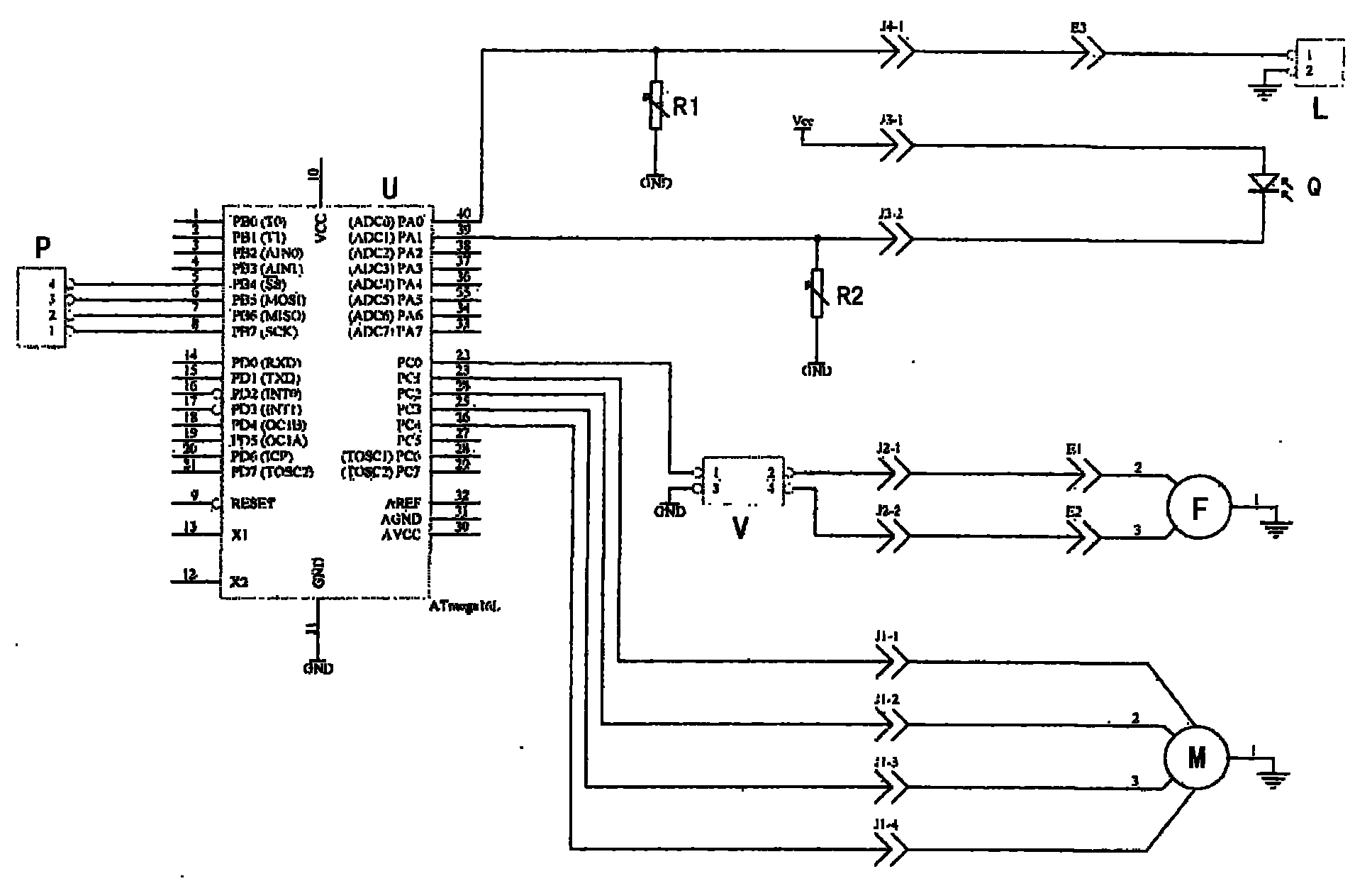

[0011] see figure 1 , the present invention comprises an infrared sensor Q, a single-chip microcomputer U, a variable frequency speed regulator V, a variable frequency speed regulating fan F, a stepping motor M and a damper, and the signal output terminal of the infrared sensor Q is connected with an input terminal PA1 of the single chip microcomputer U, and the PA1 end is connected with an input terminal PA1 of the single chip microcomputer U. A potentiometer R1 is connected between the grounds for adjusting the potential input to the microcontroller. One output terminal PC0 of the single-chip microcomputer U is connected to the frequency conversion speed regulating fan F through the frequency conversion speed regulator V, and the other output terminal PC1-PC4 of the single-chip microcomputer U is connected to the stepping motor M, and the stepping motor is used to drive the infrared burner the damper. An interface PA0 of the single-chip microcomputer U is connected with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com