System and method for detecting thickness of industrial boiler scale based on SH (Shear) wave

A technology for industrial boilers and thickness detection, applied in measuring devices, using ultrasonic/sonic/infrasonic waves, using sound waves/ultrasonic/infrasonic waves to analyze solids, etc., can solve problems such as indistinguishable, overlapping reflected waves, and limited measurement accuracy, and achieve good results The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

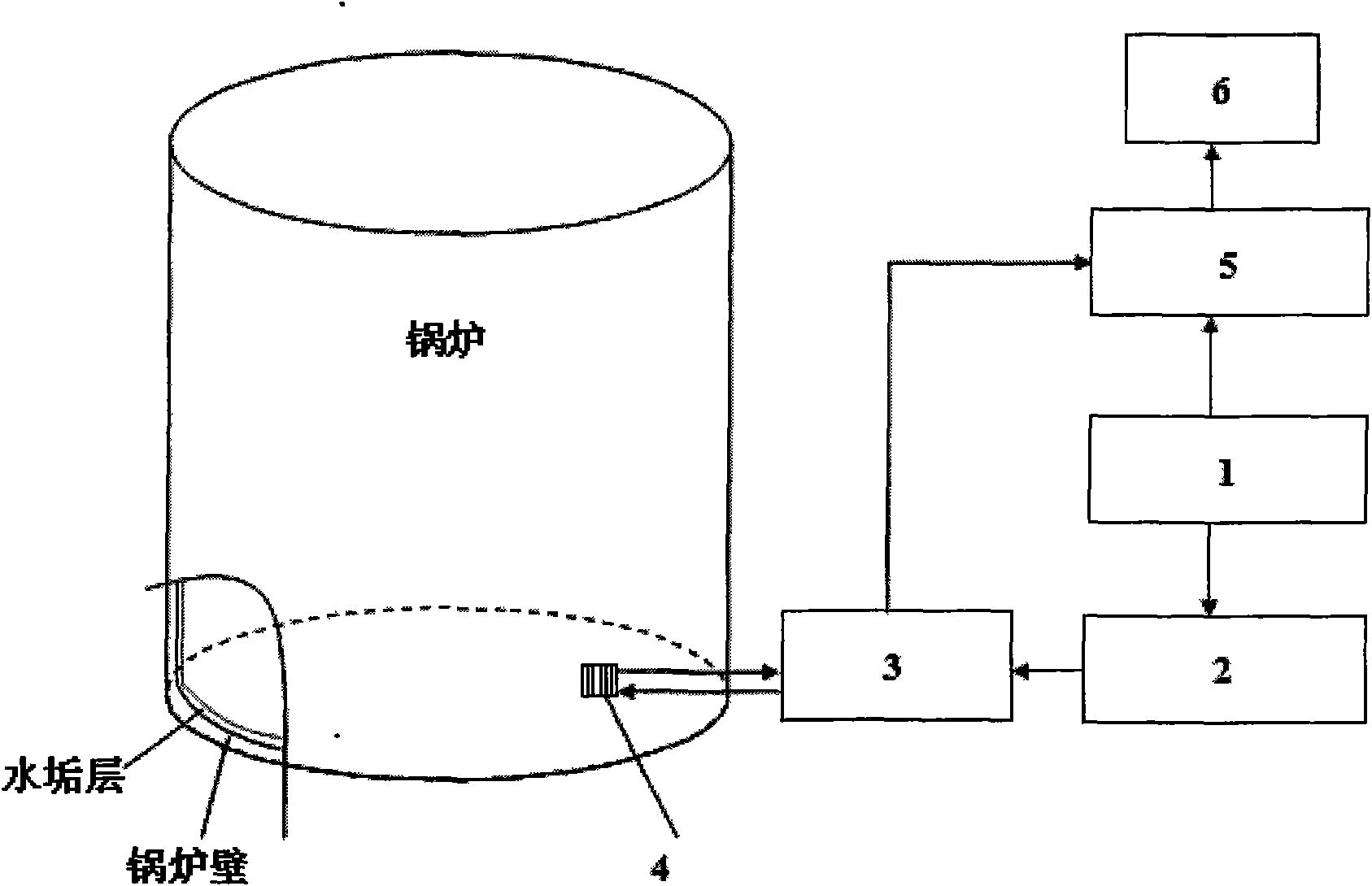

[0043] Concrete implementation steps of the present invention include:

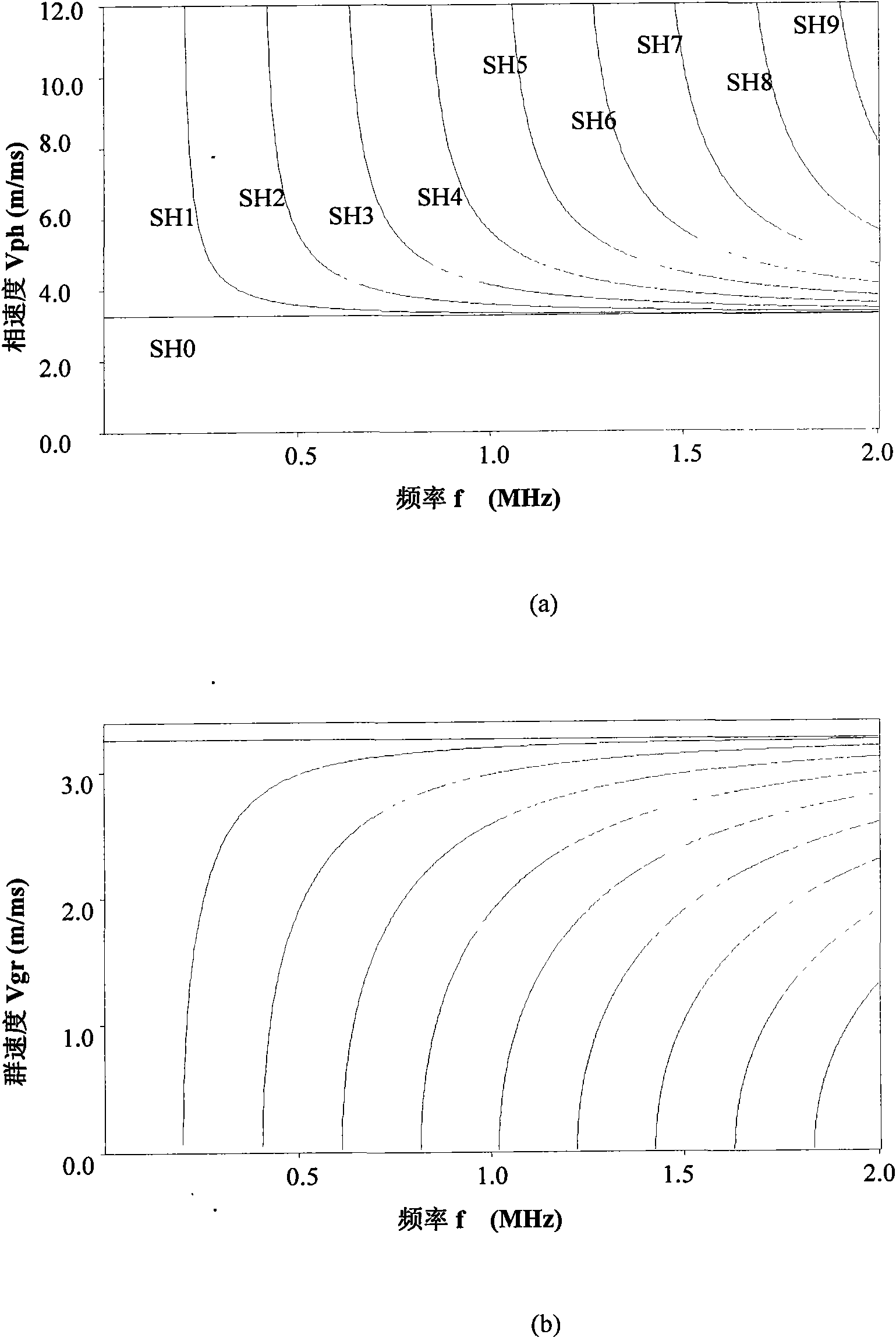

[0044] Step 1: Draw the dispersion curve

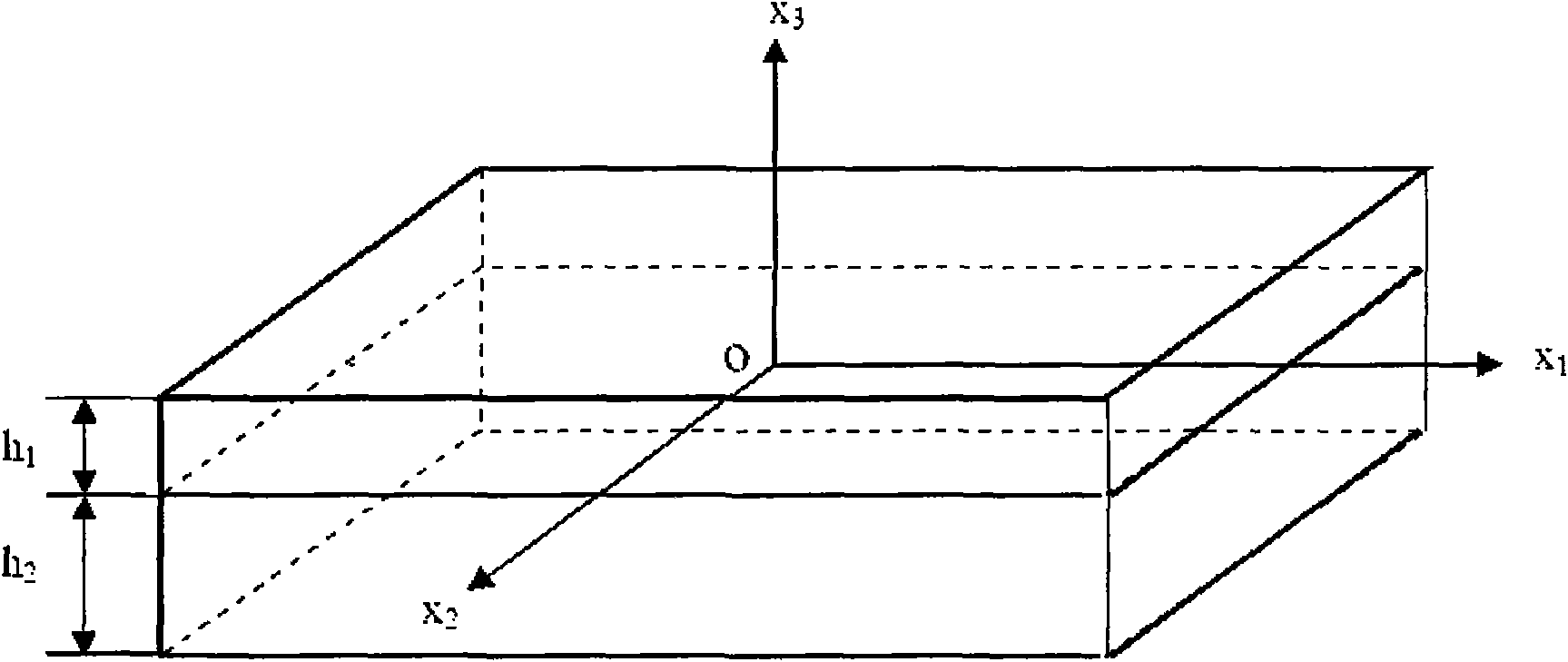

[0045] The dispersion equation (9) derived from the wave model of SH waves in the double-layer structure is used to build a model for the boiler wall and scale structure. In this example, 8mm steel plates are used as the boiler wall, and 0.5mm-3mm marble is selected. (The chemical composition is calcium carbonate, which is the same as that of ordinary scale.) As scale, the thickness of scale is selected between 0-3mm, and a dispersion curve is drawn every 0.1mm. The SH wave dispersion curves under different scale thicknesses are attached Figure 3-9 shown.

[0046] The acoustic parameters of steel plate and marble are as follows:

[0047]

[0048] Step 2: Draw the dispersion curves of the SH0 mode under different scale thicknesses

[0049] Extract the dispersion curve of the SH0 mode from the dispersion curve obtained in step 1, and draw it in the same gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com