Method and device for measuring steam humidity and diameter of water droplet of non-contact type turbine

A technology of steam humidity and water droplet diameter, which is applied in the direction of measuring device, scattering characteristic measurement, optical device, etc. The effect of easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

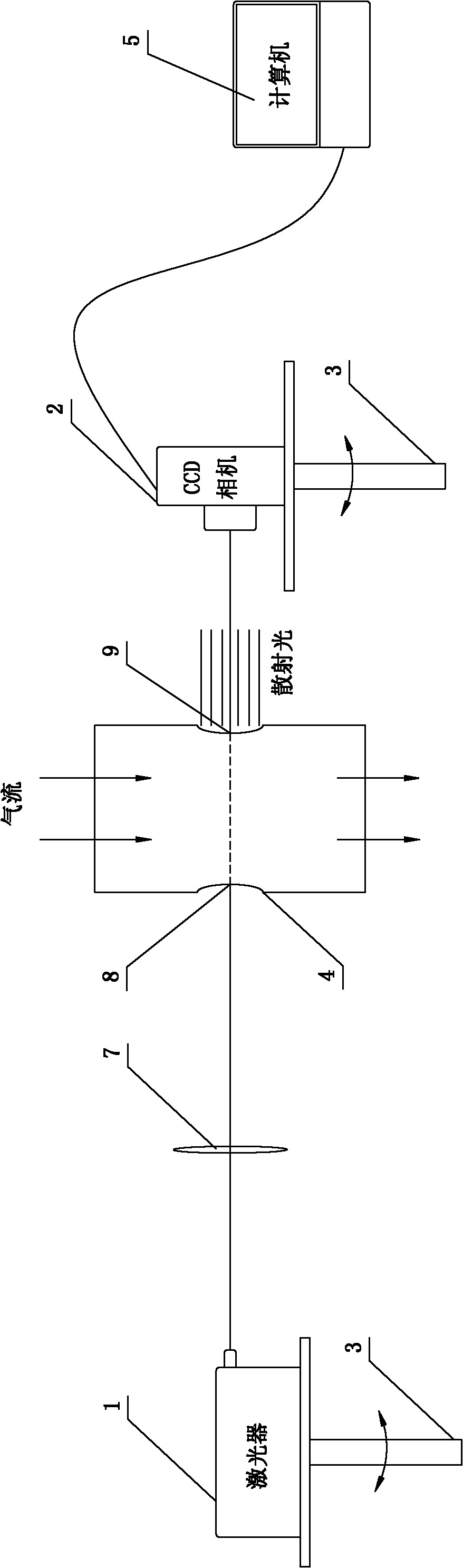

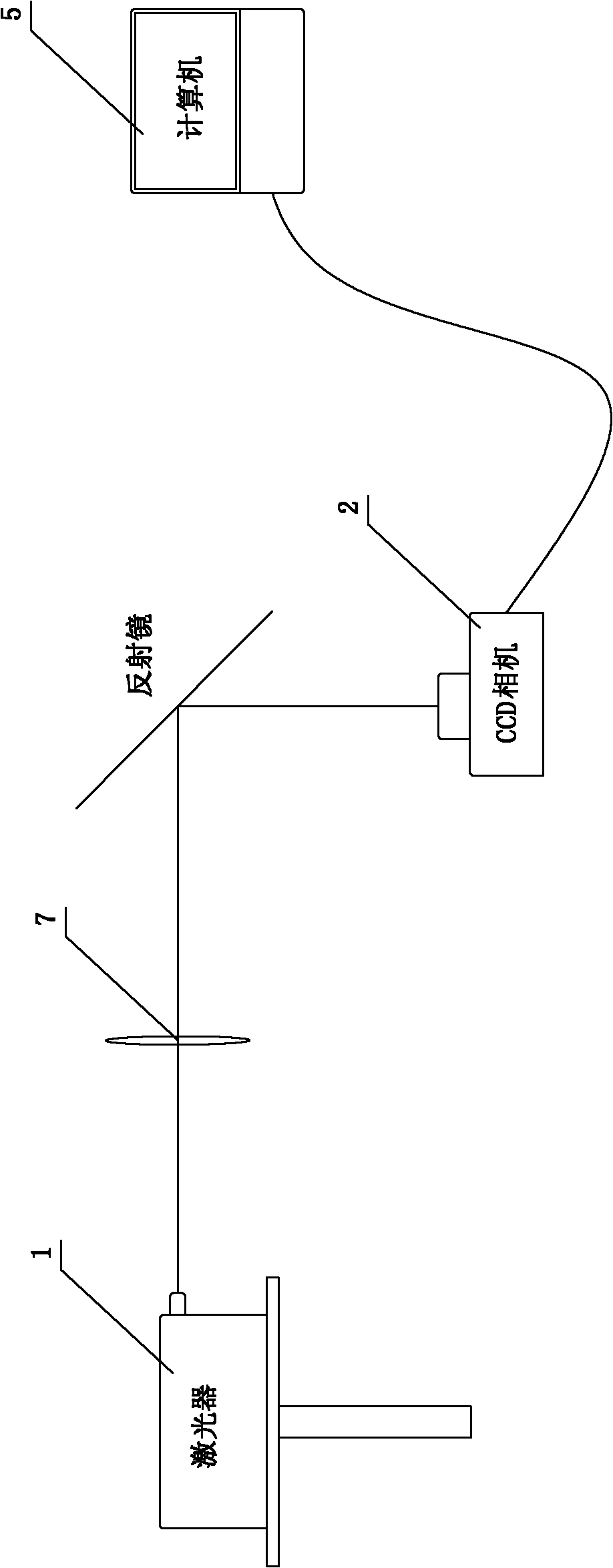

[0029] Such as figure 1 and figure 2 Shown, the present invention is a kind of method that adopts laser scattering theory and CCD technology to combine, to measure steam turbine last stage steam humidity and water drop particle diameter, in the present embodiment the specific steps of the present invention method are:

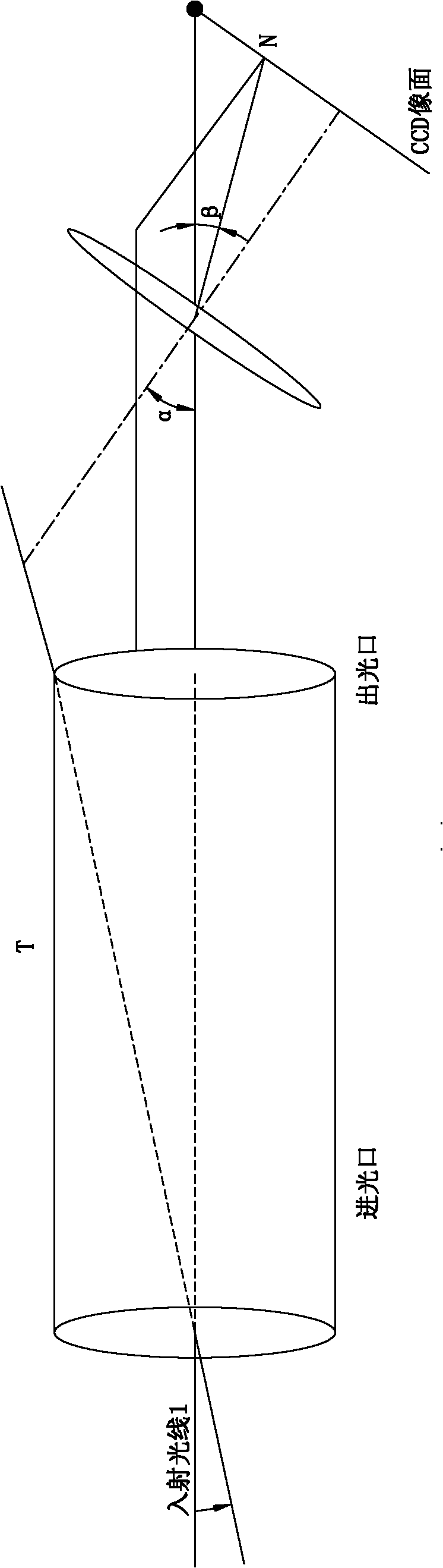

[0030] ①. Calibration: Before the measurement, the CCD camera 2 is first calibrated multiple times, and the average value of multiple calibrations is used to determine the average scale factor of the CCD camera 2. The calibration system is as follows: image 3 shown;

[0031] ②. Installation: Fix the laser 1 and the CCD camera 2 respectively on the precision two-dimensional turntable 3 on both sides of the observation window 4 of the low-pressure cylinder of the steam turbine, so that the angle between the incident ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scattering angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com