Laser triggered vacuum switch

A vacuum switch and laser technology, applied in the direction of electric switch, electronic switch, high-voltage/high-current switch, etc., can solve the problems of difficult manufacturing and processing, reduce production efficiency, affect work performance, etc., achieve convenient optical path calibration, prolong service life, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

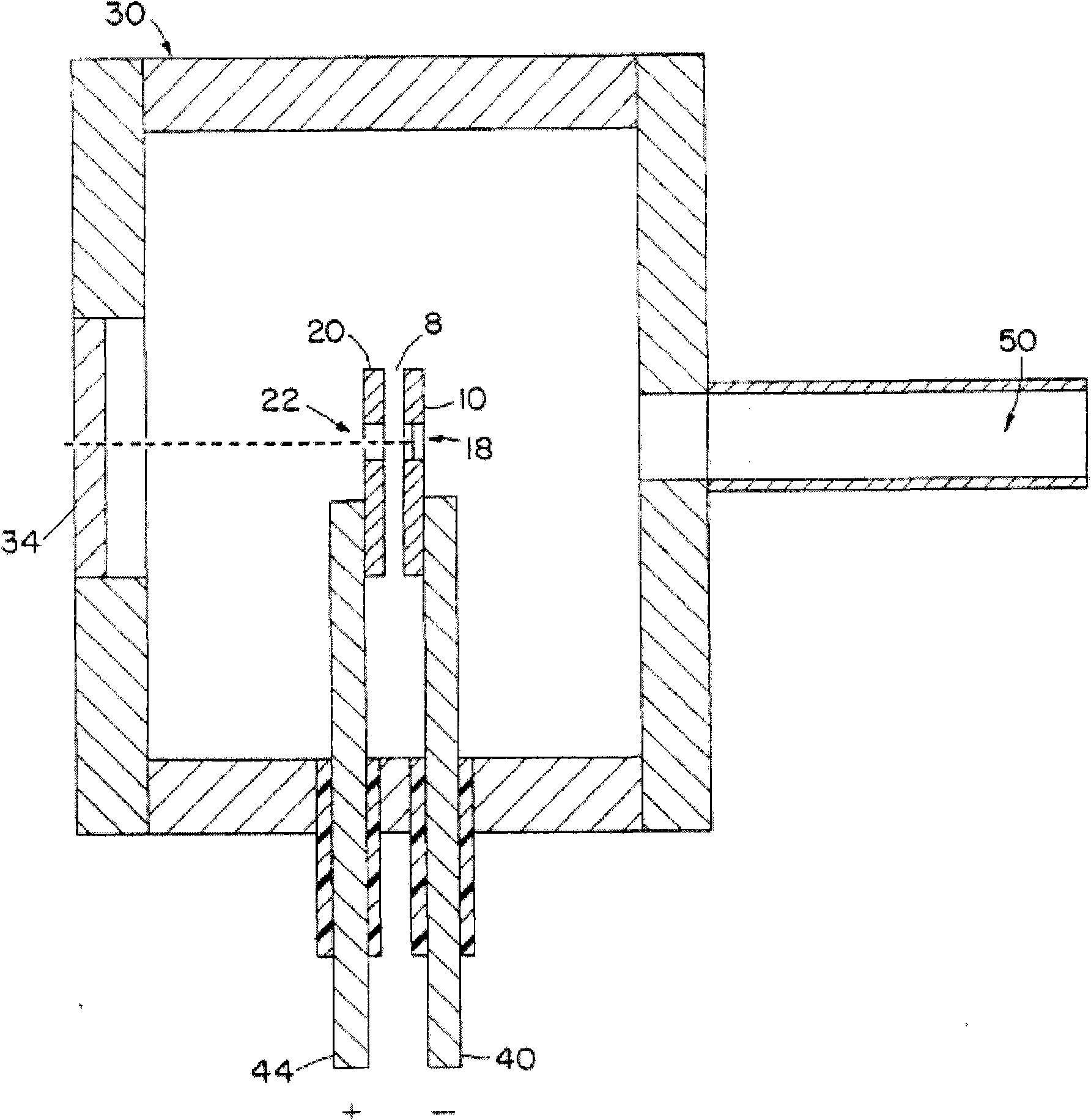

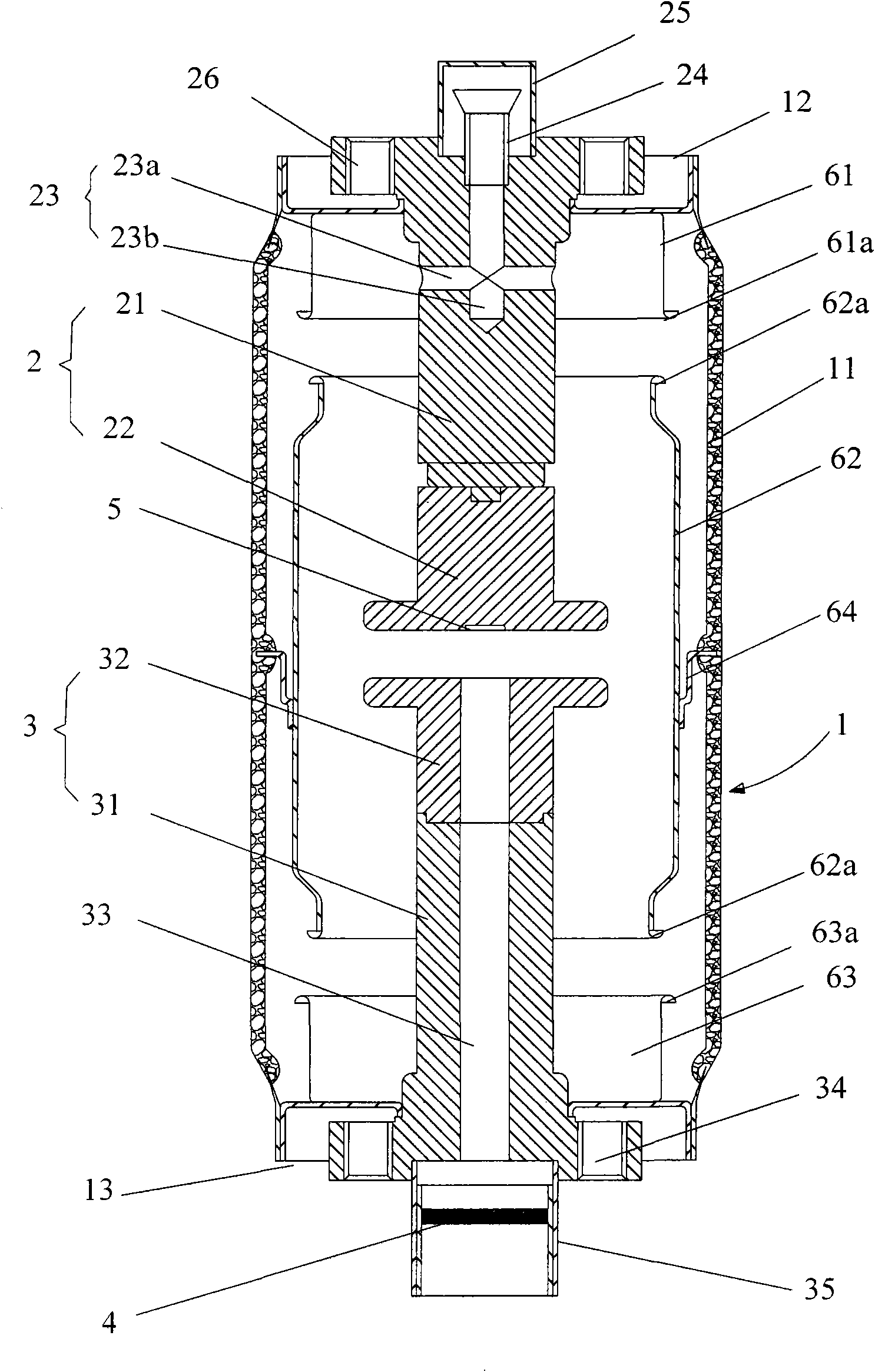

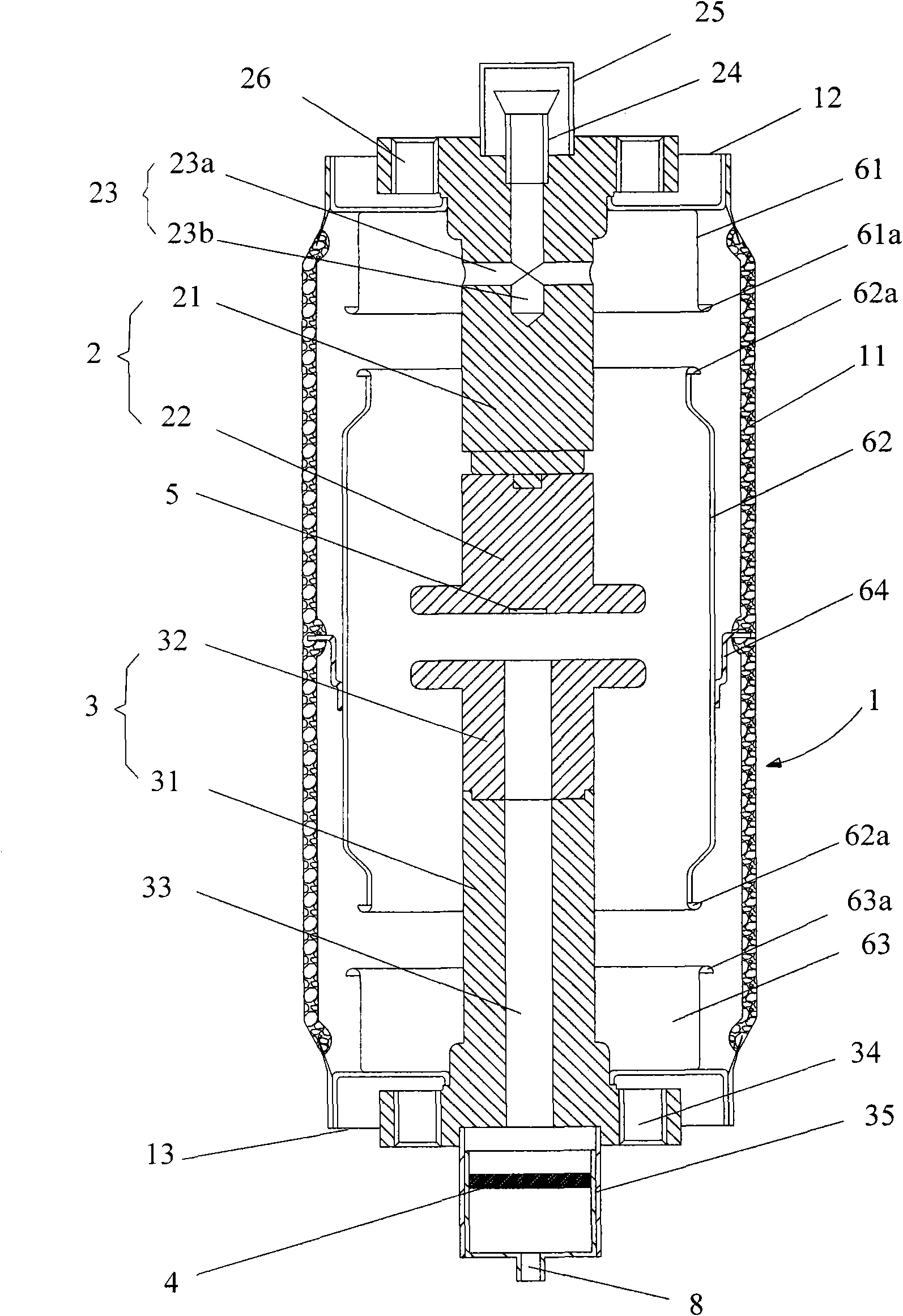

[0020] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a laser trigger vacuum switch, which has simple structure, stable trigger performance, long service life and convenient processing.

[0021] The technical solutions of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 2 As shown, the laser-triggered vacuum switch of this embodiment includes an airtight casing 1 , a first electrode 2 and a second electrode 3 arranged on the airtight casing 1 , and a laser irradiation window 4 . The first electrode 2 and the second electrode 3 are respectively fixed at two ends of the airtight casing 1 .

[0022] Specifically, the airtight housing 1 includes an insulating shell 11, an upper end flange 12 and a lower end flange 13, and the upper end flang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com