Use of flash sintering technique for the synthesis and densification of iodoapatites

An iodoapatite and rapid sintering technology, applied in radioactive purification, nuclear engineering and other directions, can solve problems such as unfavorable energy, time and cost burden, pollution, etc., and achieve the effect of eliminating the risk of diffusion and iodine volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

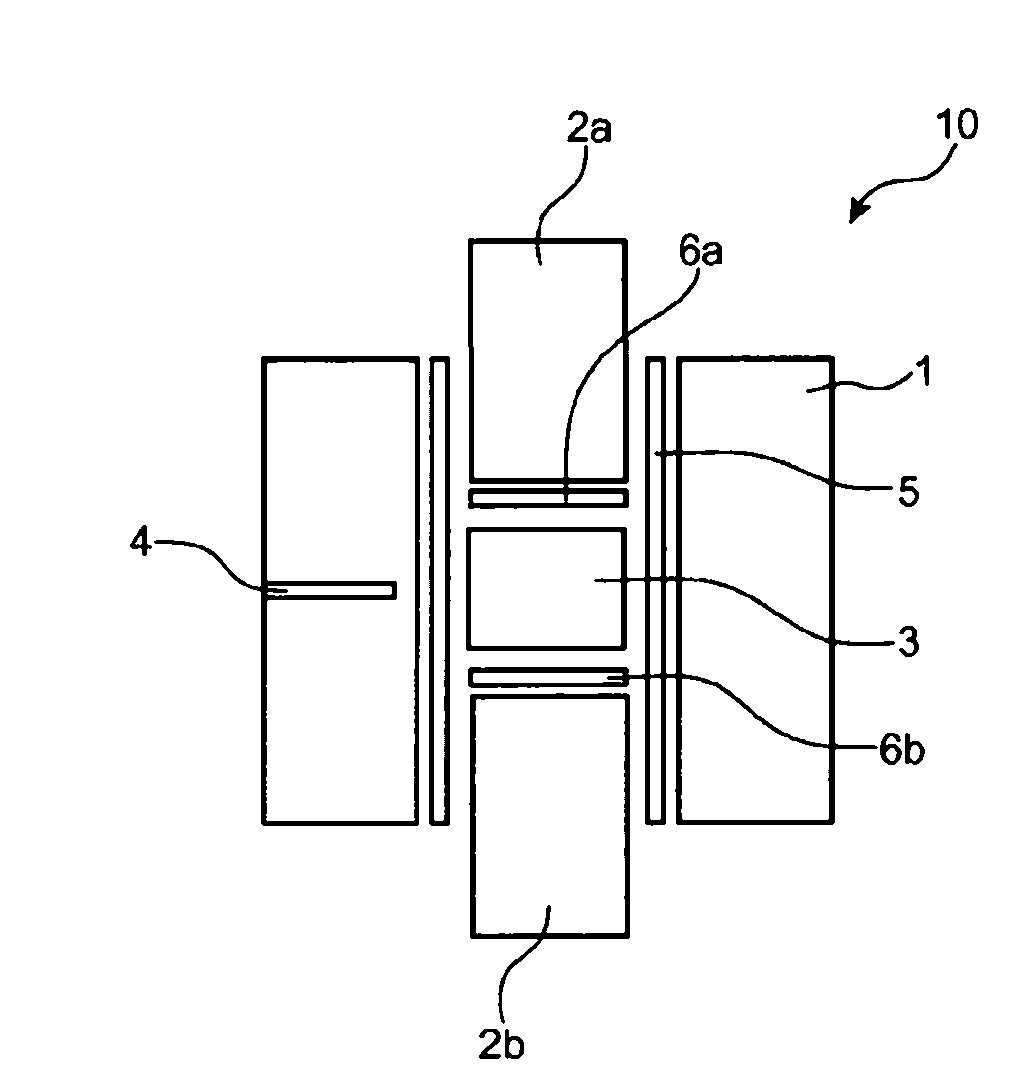

Method used

Image

Examples

Embodiment Construction

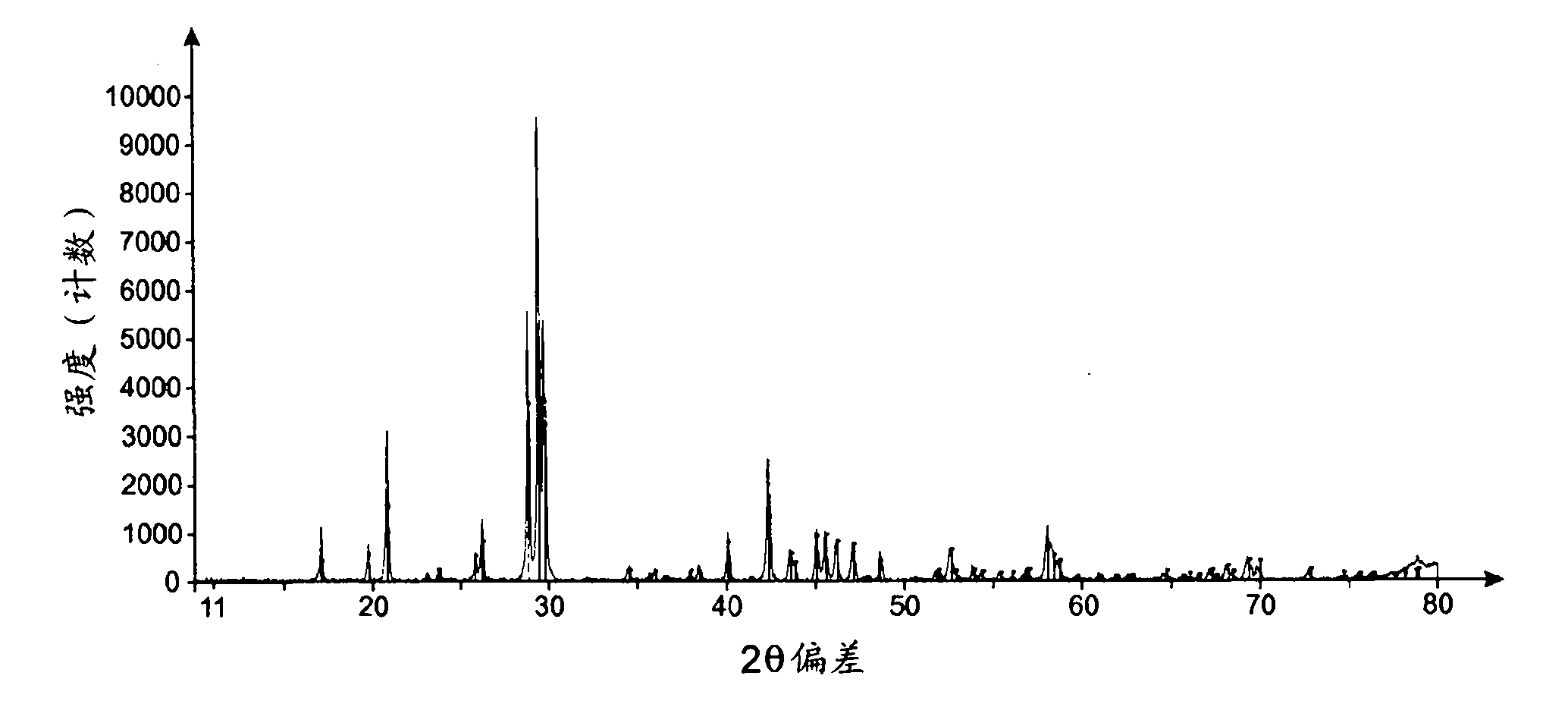

[0061] The chemical formula Pb is prepared in the following manner 10 (VO 4 ) 4.8 (PO 4 ) 1.2 I 2 of iodoapatite.

[0062] Preparation of lead vanadate phosphate / lead iodide mixture:

[0063] First, the composition Pb 3 (VO 4 ) 1.6 (PO 4 ) 0.4 lead vanadate phosphate.

[0064] The response is as follows:

[0065] 3PbO+0.8V 2 o 5 +0.4(NH 4 ) 2 HPO 4 →Pb 3 (VO 4 ) 1.6 (PO 4 ) 0.4 +0.6H 2 O+0.8NH 3 .

[0066] The lead vanadate phosphate thus obtained was then subjected to first grinding in ultrapure water (solids / water weight ratio=1) using a planetary mill equipped with a cylinder made of tungsten carbide and ball. This milling was performed for 1 hour at a speed of 300 rpm.

[0067] Next, the lead vanadate phosphate was subjected to a second milling in water. At 750cm made of zirconia 3 The milling was carried out in a cylinder with a powder / ball weight ratio equal to 1 / 9 (weight of powder = 100 g) and using as milling media a medium consisting of z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com