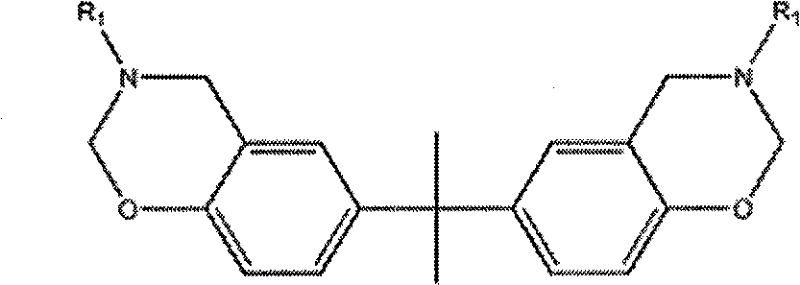

Preparation method of bisphenol A benzoxazine resin with high stability

A benzoxazine, stability technology, applied in the field of preparation of bisphenol A benzoxazine, can solve the problem of easy precipitation of benzoxazine solids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] At room temperature, add 93 grams (1mol) of aniline and 60 grams (2mol) of paraformaldehyde into a 1000ml four-necked reaction flask equipped with a reflux and water removal device, stir for 0.5 hours, then gradually raise the temperature to 50-80°C and react for 5 hours. Then add 114 grams (0.5mol) of bisphenol A, and add Pd(OAc) in 3 times on average 2 2H 2 O 1 g, heat up to 90-105 °C for 8 hours and remove water, then gradually heat up to 100-120 °C and keep reacting for 1.5 hours, add 100 g of butanone, cool the product to obtain bisphenol A benzoxazine resin solution.

Embodiment 2

[0023] At room temperature, add 59 grams (1mol) of propylamine and 216 grams (2mol) of benzaldehyde into a 1000ml four-necked reaction flask equipped with a reflux and water removal device, stir for 1 hour, then gradually raise the temperature to 55-80°C and react for 5 hours. Then add 114 grams (0.5mol) of bisphenol A, and add Mg(OAc) in 3 times on average 2 4H 2 O 1.5g, heat up to 90-105°C to react for 8.5 hours and remove water, then gradually raise the temperature to 100-120°C and keep the reaction for 1-2 hours, then add 80g of methyl ethyl ketone, cool the product to obtain bisphenol A benzox oxazine resin solution.

Embodiment 3

[0025] At room temperature, add 97 grams (1mol) of furfurylamine and 64 grams (2.1mol) of paraformaldehyde into a 1000ml four-necked reaction bottle equipped with a reflux and water removal device, stir for 1 hour, then gradually raise the temperature to 50-90°C and react for 4 Hour. Then add 114 grams (0.5mol) of bisphenol A, and add Co(OAc) in 3 times on average 2 4H 2 O 3 grams, heat up to 90-110 ° C for 8.5 hours and remove water, then gradually heat up to 100-120 ° C and keep the reaction for 1-2 hours, add 100 grams of ethylene glycol methyl ether, and cool the product to obtain bisphenol A benzene Oxazine resin solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com