Device and method for fabric dyeing with supercritical carbon dioxide fluid

A carbon dioxide, fabric dyeing technology, applied in the field of textile dyeing and finishing, can solve problems such as difficulty in realization, achieve broad application prospects, easy operation, and reduce non-uniform loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The dyed fabric used in this embodiment is 240 polyester pongee (75D / 75D low-elastic polyester yarn, 130.0g / m 2 ), the dye used is Celliton Disperse Red GG (Disperse C.I.Red 17, o.m.f is 0.1%).

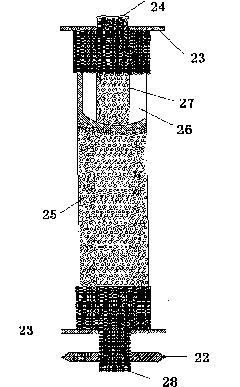

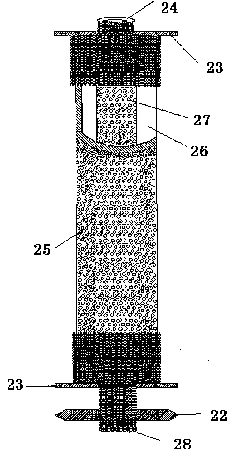

[0022] See attached figure 2 , the dyed warp beam provided by the present embodiment, the warp beam outer layer 26 in contact with the fabric is a hollow seamless shaft, the material is Teflon, and a non-thermally conductive material resistant to supercritical carbon dioxide fluid and with a certain hardness can also be used. The shaft body is covered with 800-mesh micropores; the warp shaft inner layer 27 is a hollow shaft, and the shaft body is covered with circular holes with a diameter of 6 mm, and the distance between each hole is 2 mm; the warp shaft outer layer and the warp shaft inner layer are coaxially installed, Their upper and lower ends are respectively fixed on the upper sealing head 24 and the lower sealing head 28, and a buffer cavity 26 is formed between the ...

Embodiment 2

[0042] This embodiment adopts Celliton disperse red GG (Disperse C.I.Red 17, o.m.f is 0.1%) to 240 polyester pongee (75D / 75D low elastic polyester yarn, 130.0g / m 2 ) for dyeing processing; the dyeing conditions are 20MPa supercritical carbon dioxide fluid, the ratio of each cycle of the fluid to the subsequent static dyeing time is 1 / 10, the total dyeing time is 2hr, and the dyeing temperatures are 90°C, 100°C, 120°C, 140°C ℃; the micropores in the outer layer of the dyed warp shaft are δ00 mesh.

[0043] According to the method of Example 1, the 240 polyester pongee was dyed and processed under the above-mentioned different temperature conditions, and the specific steps and other conditions were as described in Example 1.

[0044] Table 2 shows the experimental results of dyeing 240 polyester pongee with Celliton red GG (0.1% o.m.f) at different temperatures using the method described in this example.

[0045] Table 2

[0046]

[0047] From the data shown in Table 2, it ...

Embodiment 3

[0049] This embodiment adopts Celliton disperse red GG (Disperse C.I.Red 17, o.m.f is 0.1%) to 240 polyester pongee (75D / 75D low elastic polyester yarn, 130.0g / m 2 ) for dyeing processing; the dyeing conditions are 20MPa supercritical carbon dioxide fluid, the ratio of each cycle of the fluid to the subsequent static dyeing time is 1 / 10, the dyeing temperature is 120°C, and the total dyeing time is 1hr, 4hr, 5hr; The micropores of the outer layer are 100 mesh.

[0050] According to the method of Example 1, the 240 polyester pongee was dyed and processed under the above-mentioned different dyeing time conditions, and the specific steps and other conditions were as described in Example 1.

[0051] Table 3 shows the experimental results of dyeing 240 polyester pongee with Celliton red GG (0.1% o.m.f) under different dyeing time conditions by using the method described in this example.

[0052] table 3

[0053]

[0054] As can be seen from the data shown in Table 3, even in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com