Wet method ball mill belly expansion fault prediction device and method

A wet ball mill and fault prediction technology, which is applied in the testing of measuring devices, machine/structural components, and vibration measurement, etc., can solve the problems of noise detection devices easily disturbed, high working noise, and poor application effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

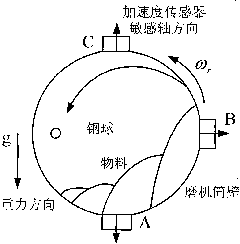

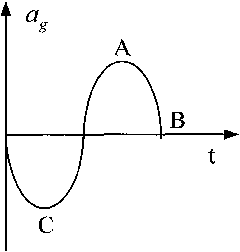

[0037] The present invention detects the vibration acceleration signal of the cylinder wall through the acceleration sensor arranged on the outer surface of the cylinder wall of the wet ball mill (hereinafter referred to as the ball mill), and predicts whether the ball mill will have belly swelling failure according to the average intensity of the vibration acceleration signal.

[0038] The acceleration sensor that the present invention adopts satisfies the following requirements: the minimum frequency response of the acceleration sensor (unit Hz) lower than the speed ω of the ball mill r (Convert the speed unit to "rev / s" for comparison with the frequency unit Hz), the highest frequency response (unit Hz) higher than the highest frequency f of the vibration acceleration signal generated by the steel ball in the ball mill colliding with the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com