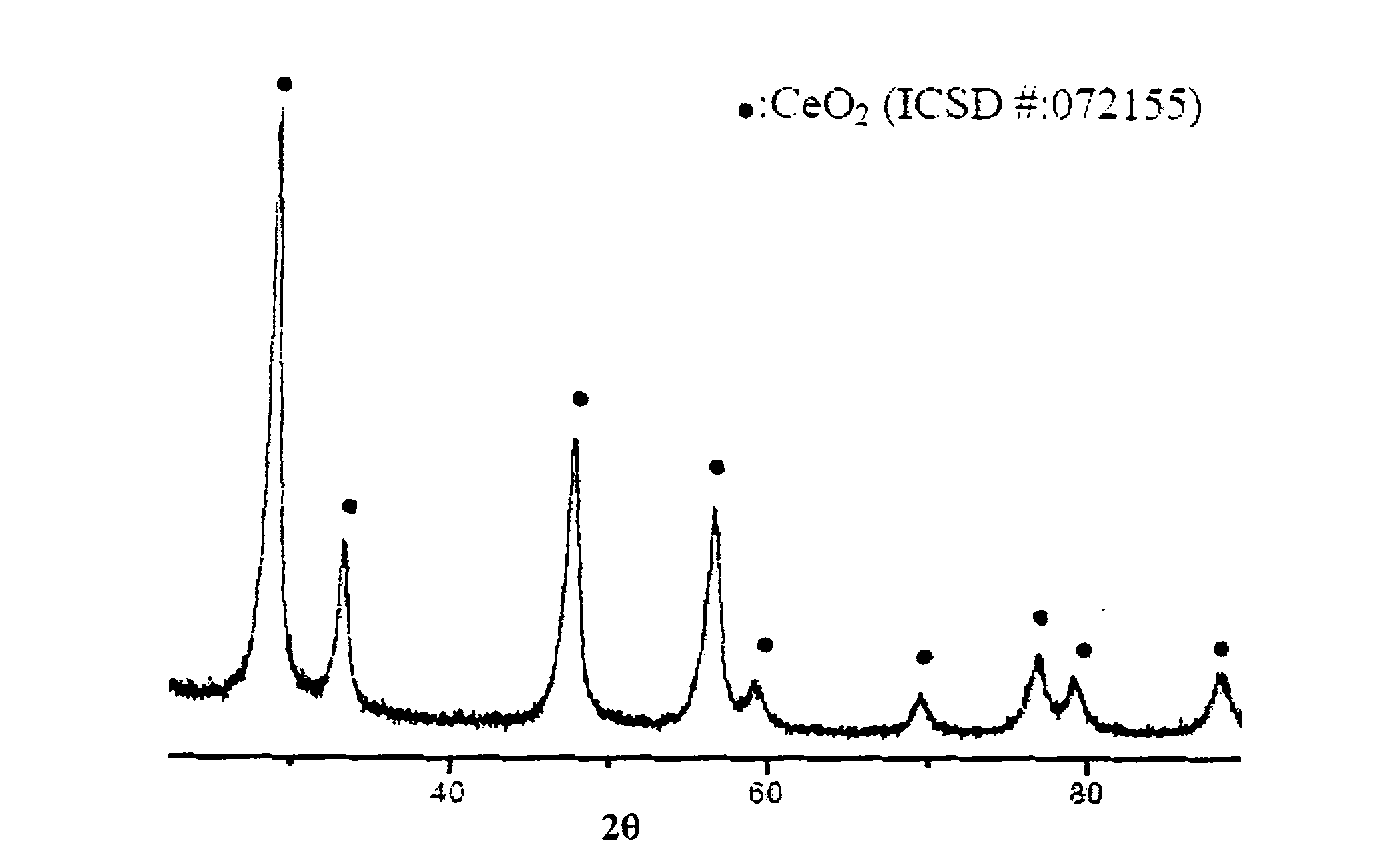

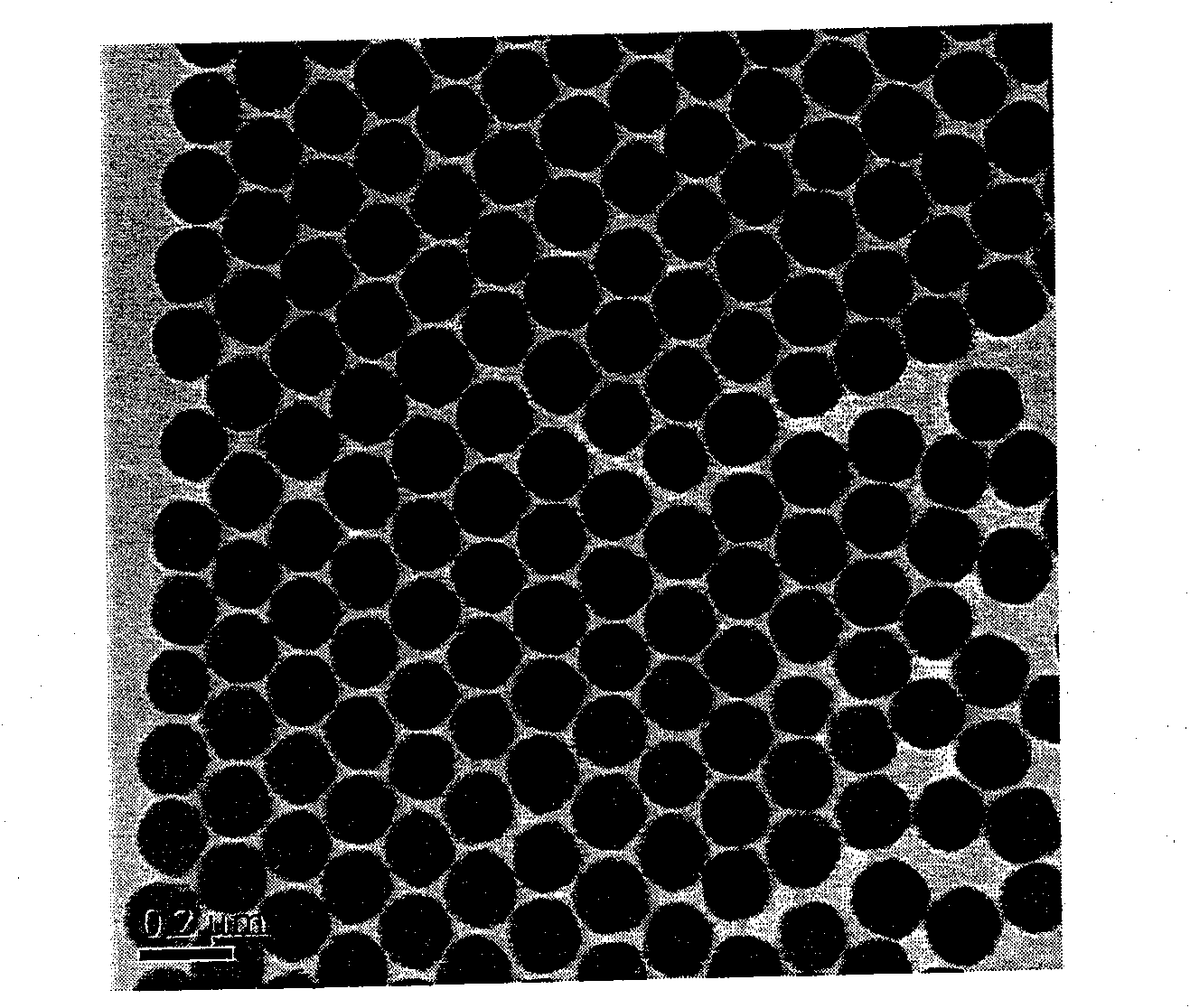

Cerium dioxide microsphere used as dimension standard material

A ceria and standard substance technology, applied in the field of ceria microspheres, can solve the problems of poor particle size uniformity, high degree of particle agglomeration, irregular morphology, etc., achieves good sphericity, is not easy to be eroded by bacteria, and has a large specific gravity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mix 19.6g of cerium nitrate, 9.8g of polyvinylpyrrolidone (K90) and 400g of water, stir to dissolve, dilute to 500mL, pour it into a 1000mL hydrothermal kettle, set the hydrothermal temperature to 140℃, rotate speed 800rpm, and proceed A hydrothermal reaction, the reaction stopped after 48h. After the reaction kettle is cooled, the reaction product mixture is centrifuged at a centrifugal temperature of -4°C and a centrifugal speed of 10000 rpm for 20 minutes. The particles settle at the bottom of the centrifuge tube, and the supernatant is slowly poured into the centrifuge tube that has been cleaned beforehand. Collect and discard the bottom particles, centrifuge the supernatant again at the same temperature and speed for 20 minutes at high speed, remove the bottom particles of the centrifuge tube, collect the supernatant, and repeat the process twice to obtain the supernatant as the inorganic-organic composite template solution . Pour the composite template solution in...

Embodiment 2

[0028] Mix 55.6g of cerium nitrate, 48.5g of polyvinylpyrrolidone (K30) and 650g of water, stir to dissolve, dilute to 800mL, pour it into a 1000mL hydrothermal kettle, set the hydrothermal temperature to 170℃, rotate speed 25rpm, and proceed A hydrothermal reaction, the reaction was stopped after 24h. After the reactor is cooled, the reaction product mixture is centrifuged at a centrifugal temperature of -3°C and a centrifugal speed of 10000 rpm for 20 minutes. The particles settle at the bottom of the centrifuge tube, and the supernatant is slowly poured into the centrifuge tube that has been cleaned beforehand. Collect and discard the bottom particles, centrifuge the supernatant again at the same temperature and speed for 20 minutes at high speed, remove the bottom particles of the centrifuge tube, collect the supernatant, and repeat the process twice to obtain the supernatant as the inorganic-organic composite template solution . Pour the composite template solution into a...

Embodiment 3

[0031] Mix 158.8g of cerium chloride, 165.3g of polyvinylpyrrolidone (K60) and 1900g of water, stir to dissolve, dilute to 2100mL, pour it into a 3000mL hydrothermal kettle, set the hydrothermal temperature to 180°C, and rotate at 450rpm. The first hydrothermal reaction, the reaction was stopped after 36h. After the reactor is cooled, the reaction product mixture is centrifuged at a centrifugal temperature of 0°C and a centrifugal speed of 20,000 rpm for 25 minutes. The particles settle at the bottom of the centrifuge tube. The supernatant is slowly poured into the centrifuge tube that has been cleaned beforehand. The bottom particles are discarded, and the supernatant is centrifuged again at high speed for 25 minutes at the same temperature and speed to remove the bottom particles of the centrifuge tube, collect the supernatant, and repeat the treatment twice to obtain the supernatant as the inorganic-organic composite template solution. Pour the composite template solution in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape factor | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com