Intelligent micro-pressure full-automatic soybean milk machine

A soybean milk machine, fully automatic technology, applied in the fields of boiling milk, intelligent micro-pressure automatic soybean milk machine, automatic pulping and automatic filtering device, and food refining, which can solve the complex structure, inconvenient operation, no Reservation function and other issues to achieve the effect of simple product structure, fast cooking speed, and removal of beany smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] According to the technical scheme proposed, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

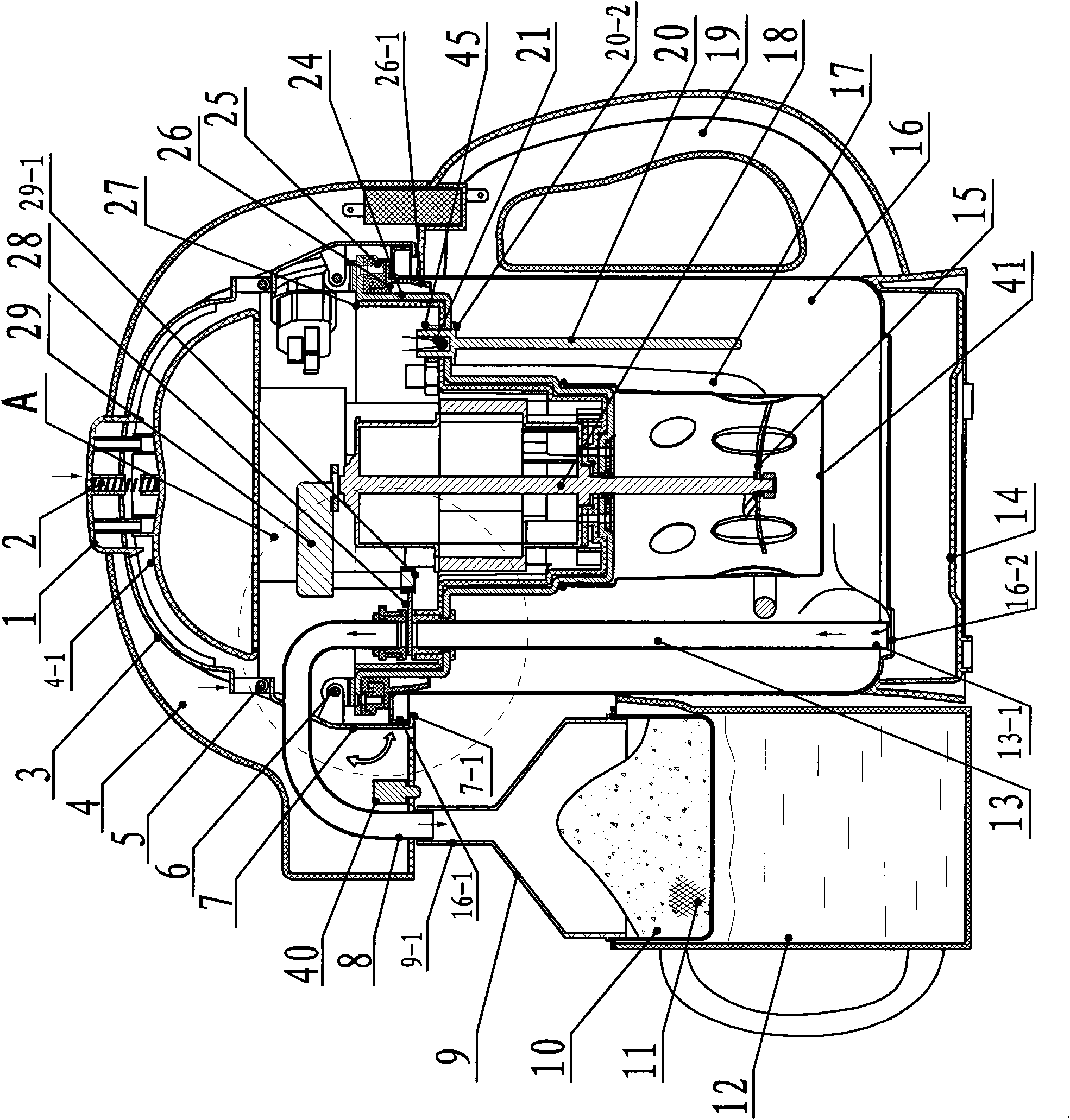

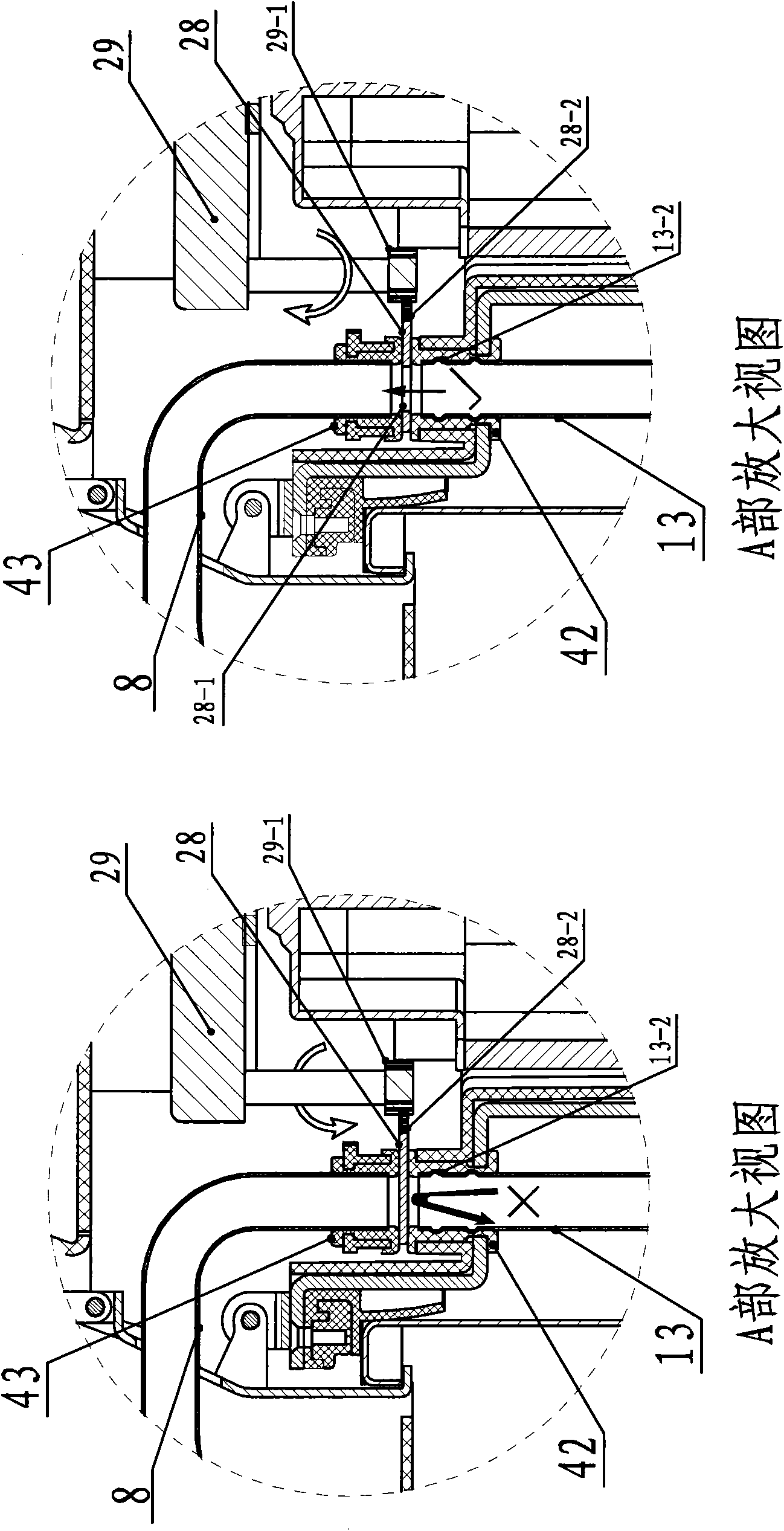

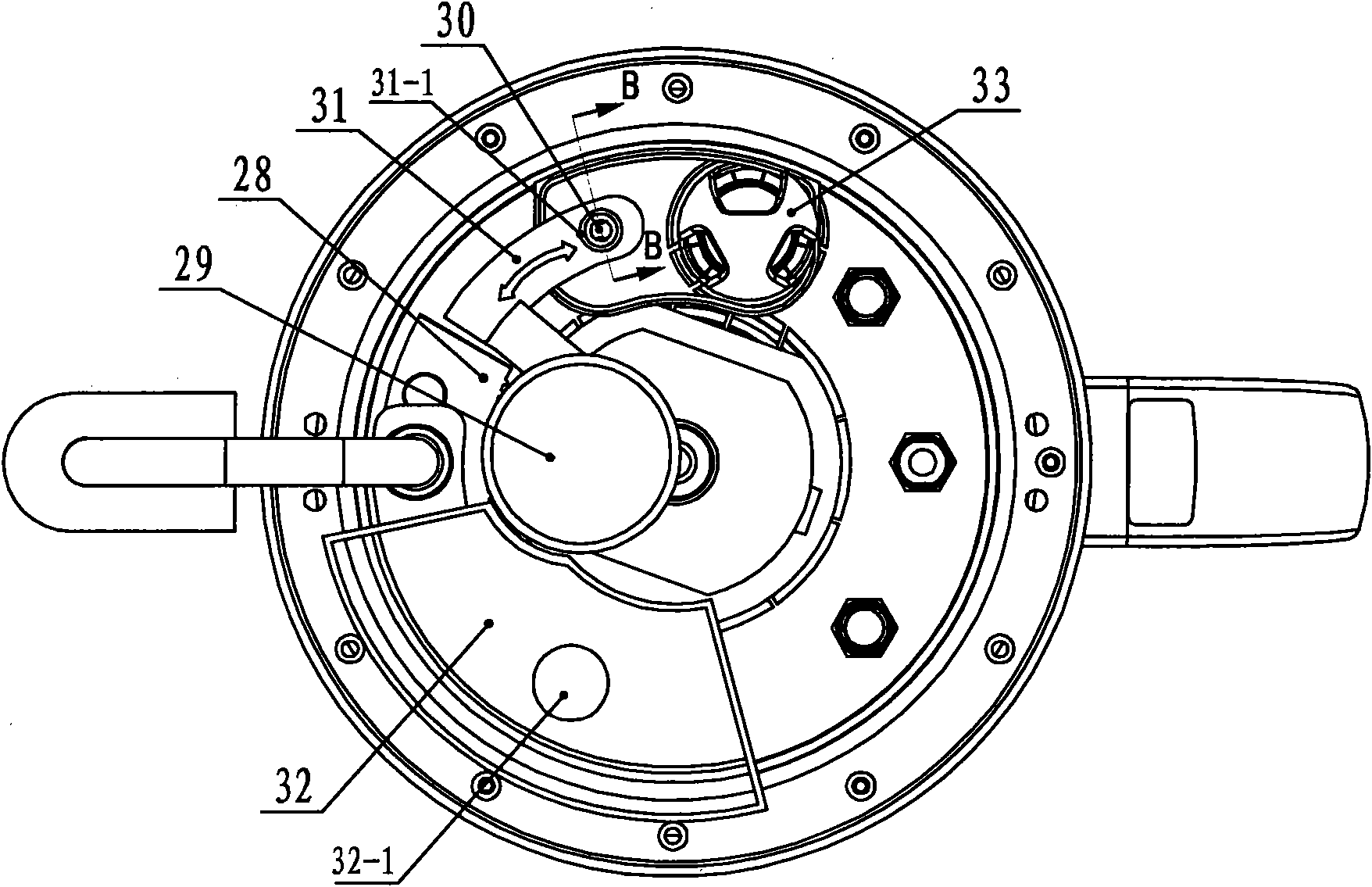

[0025] The first example is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 shown.

[0026] An intelligent micro-pressure full-automatic soymilk machine, which is a motor top-mounted machine base structure, consists of four main parts: machine base, cup body, soybean milk cup, and automatic filter; 27. Machine base cover 24, machine base buckle cover mechanism, sealing mechanism, pulp refining and pulp cooking mechanism, temperature measurement and pressure control mechanism, automatic pulp discharge mechanism, safety interlock mechanism, automatic bean adding mechanism, and safety pressure relief device; The automatic filter is made up of a blowout preventer 9, a filter frame 10, a filter gauze 11, and a soybean milk cup 12;

[0027] The first embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com